ENVIRO-TEC

76

FORM ET115.24-NOM4 (819)

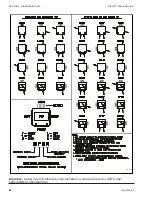

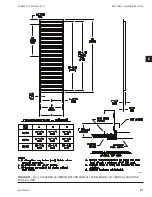

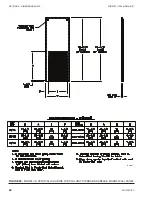

SECTION 6 - DIMENSIONAL DATA

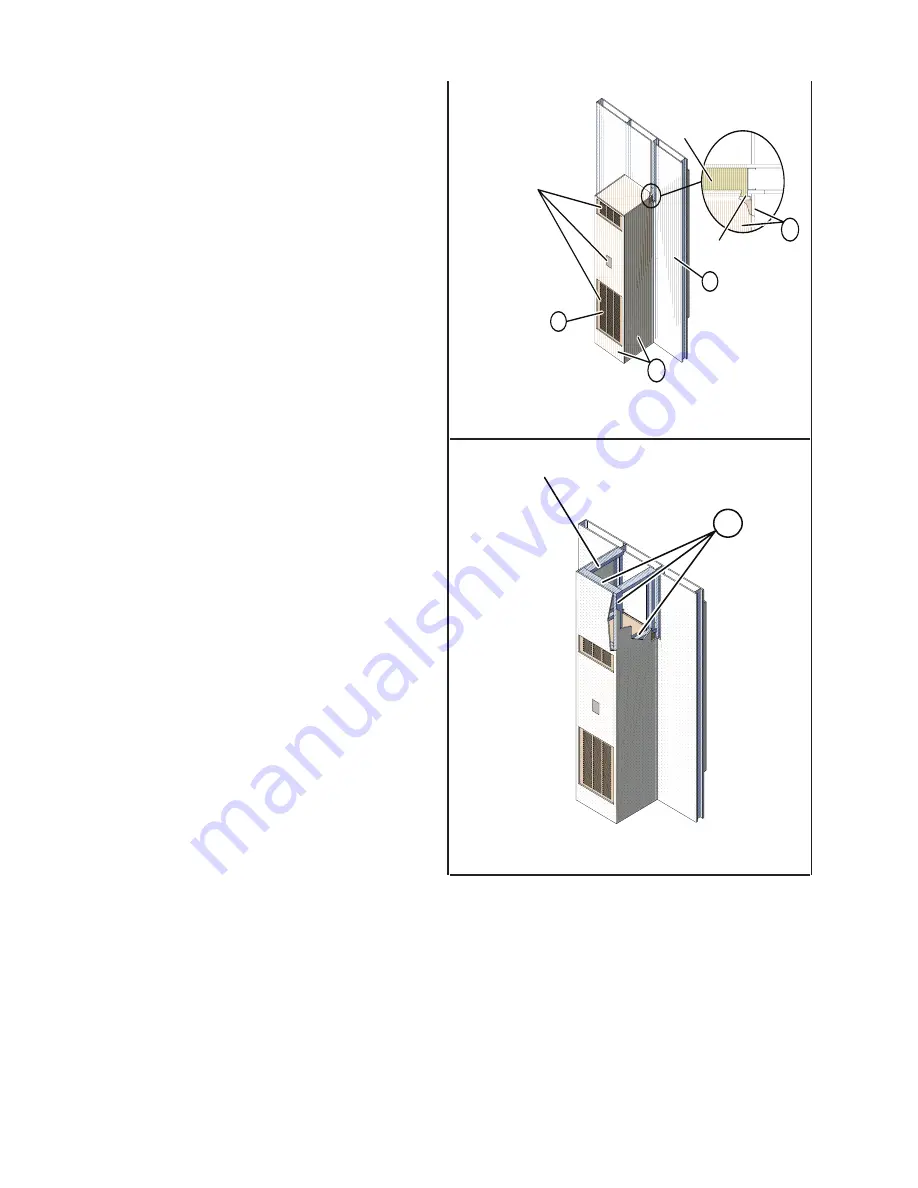

b. The gypsum panel installed to the face of the

unit should be applied directly to the front

of the unit, unless a wall recessed return air

grille is used, in which case this panel will be

furred-out. Any supply air, return air, or ther-

mostat openings shall be let-in as necessary.

c. Attach gypsum board to unit with sheet met-

al screws spaced 8” O.C. around the perim-

eter and 12” O.C. in the field, ensuring that

screws are not located where they might pen-

etrate interior working of unit.

d. Gypsum board shall be tightly butted against

the wall assembly on all exposed sides, in-

cluding top of unit.

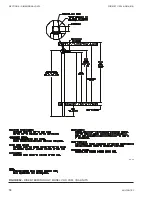

11. For alternate installation per

Figure 54 on page

76

, unit framing must be installed to top of unit.

a. Install minimum 25 GA, nominal 3-1/2”

wide, steel track to the top of the fan coil

unit, at top front and two top sides as shown

in

Figure 54 on page 76

.

b. Attach steel track using sheet metal screws

spaced 12” O.C.

c. Install identical steel track to the ceiling or

floor assembly using appropriate anchors.

Friction fit minimum 25 GA nominal 3-1/2”

steel studs into the top and bottom track and

secure with pan head screws.

d. Install one stud at each corner of the fan coil

unit.

e. Install gypsum board to the front and side of

the fan coil unit as described in Step 10.

f. Extend the gypsum board to the ceiling or

floor assembly, attaching to steel studs and

track with Type S screws spaced maximum

8” O.C.

12. Risers shown in the standard location. Risers may

be installed on the left or right side of Unit A. Wall

construction should remain the same, regardless

of riser location.

Gypsum may have cut out to

accomodate supply, return

and thermostat

1

1A

2

Factory Installed

Insulation

1A

Factory Installed

Gypsum

LD19316

FIGURE 53 -

STANDARD INSTALLATION

Attached to pre-existing ceiling or floor assembly

1Bi

FIGURE 54 -

ALTERNATE INSTALLATION

LD19316

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...