24431

Rev. A

10/12

http: www.networketi.com

Environmental Technology, Inc.

20 of 94

Automatic Air Dehydrator

ADH

®

SIROCCO™

Instruction Manual

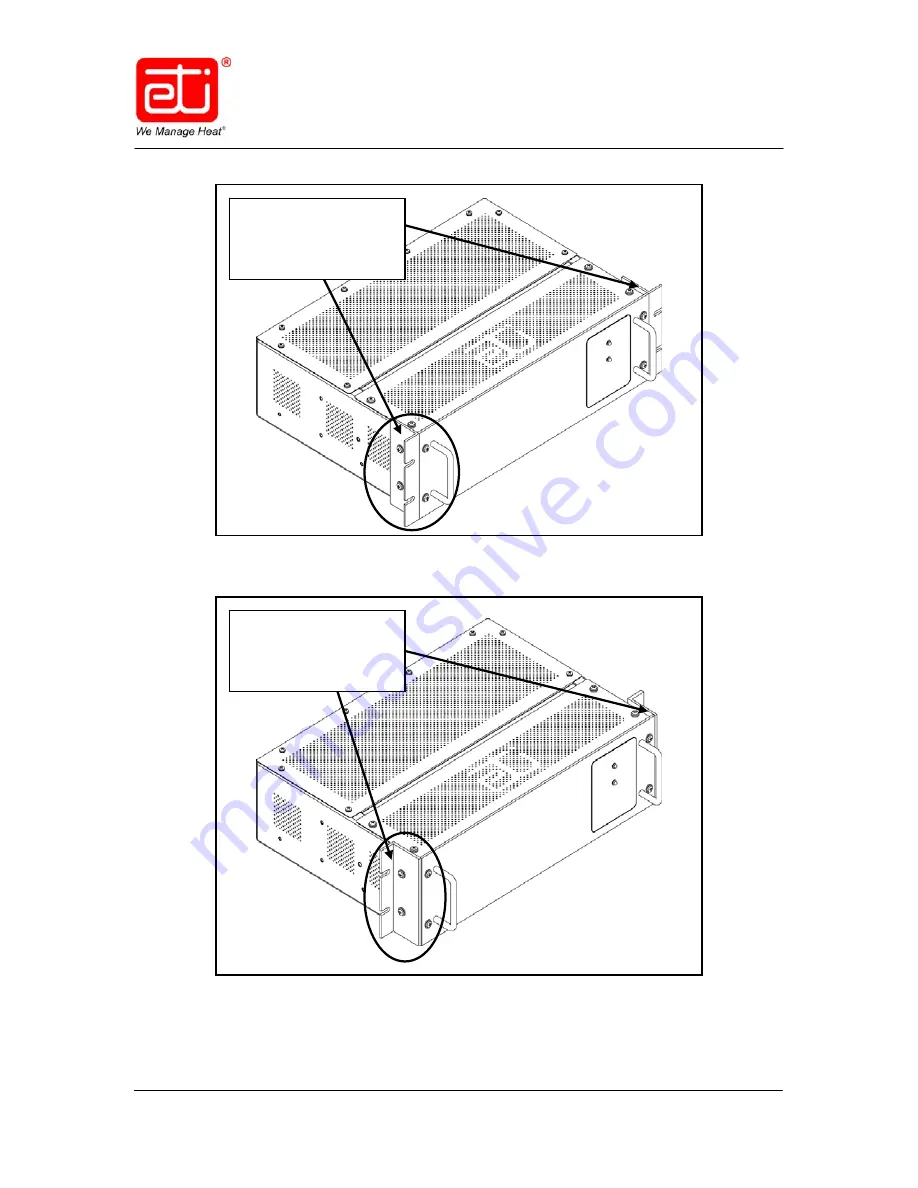

Figure 11. MOUNTING BRACKETS IN FLUSH MOUNT POSITION.

Figure 12. MOUNTING BRACKETS IN 2-INCH DEPTH POSITION.

Install mounting

brackets as shown for

flush mount installation

(2 places).

Install mounting

brackets as shown for

2-inch depth mount

installation (2 places).