www.enware.com.au

Call 1300 369 27 15

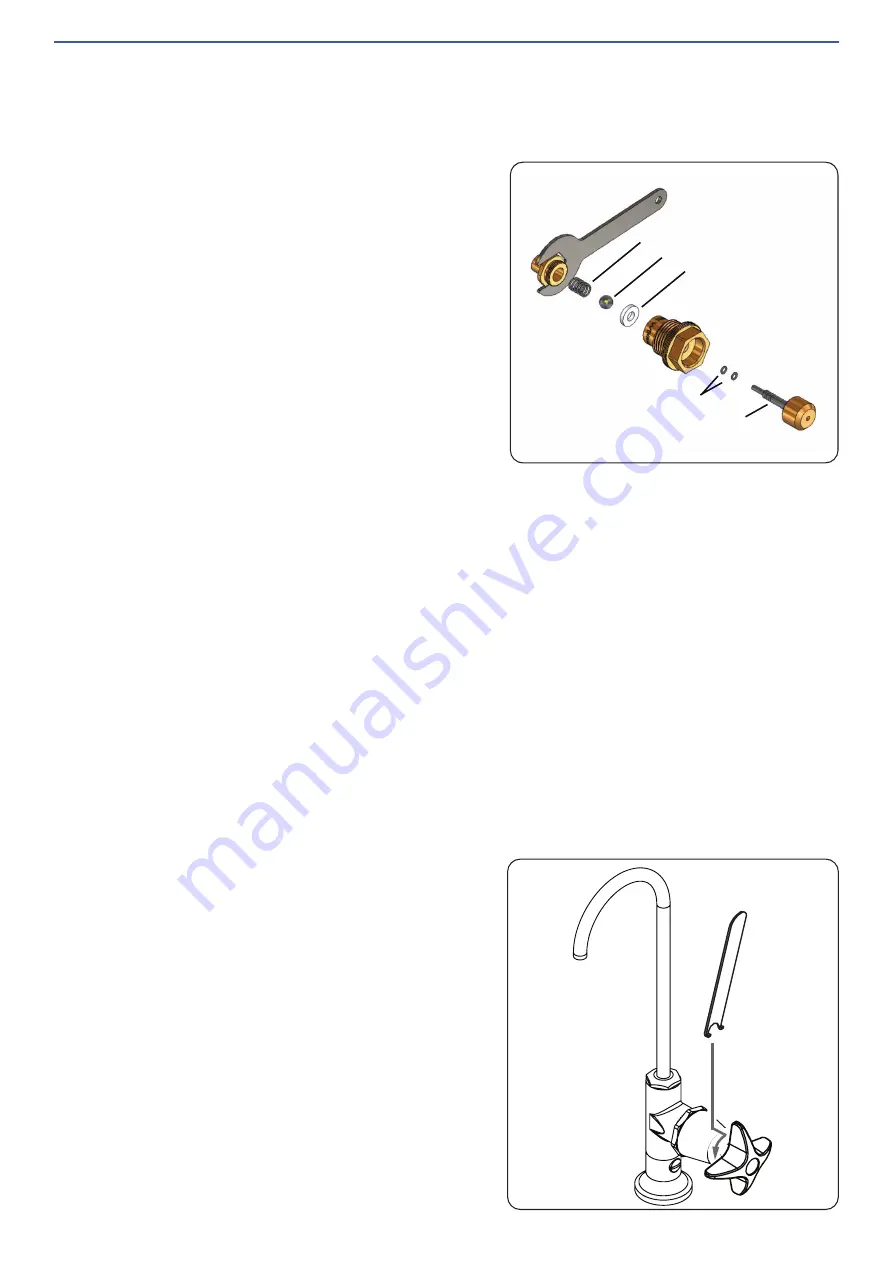

SERVICING THE SBA WITH SERVICE KIT

1. Pull the piston assembly out from the SBA and

remove the 2 piston o-rings.

2. Use a spanner to unscrew bottom inlet port,

remove spring and stainless steel ball in the port.

3. Insert a small screw driver in centre hole of the

ball seating washer and remove the ball seating

washer by levering it out.

4. Clean all brass and chrome components.

Remove any debris or scale, especially on the

piston, spindle and in the dome. Use a diluted

solution of CLR for cleaning if necessary. Check

all brass components for wear or damage.

5. Lightly grease the two small piston o-rings

with a silicon based, potable water approved grease (e.g. Hydroseal Tap Lubricant or

Molykote111) and fit the two o-rings to the piston.

6. Now reassemble the SBA with new components from Service Kit. Place the ball seating

washer, ball and spring back in the bottom inlet port, and tighten up the bottom inlet port

to the SBA. Refit the seat o-ring and seating washer. Push the piston into the SBA.

RE-FITTING THE TOP ASSEMBLY

1. Grease the inside of the dome around spindle mechanism

2. Fit the dome and handle assembly.

3. Adjust the position of dome. SEE DOME ADJUSTMENT

SBA SPRING

STAINLESS STEEL BALL

BALL SEATING WASHER

PISTON O-RINGS

PISTON

HANDLE

If the handle feels loose, check that the handle

insert is fitted, and tighten with the Anti Vandal

Handle Key.

To take off handle, use the Anti-Vandal Handle Key

to loosen the insert. Handle pulls off the spindle.