ADJUSTMENT DATA

NOZZLE

TYPE

Pump

pressure

Burner flow-rate

3

Air gate

adjustment

2

Disc position

adjustment

Burner model

GPH

bar

kg/h

Set-point n°

Set-point n°

0.85 3.40

3.5 6

0.75 2.90

2.5

4.5

0.60 2.40

2 3

0.50 1.80

1.5

0.5

RiNOx 35

(with pre-heating

0.40

12

1.50 1

0.5

NOTE:

The values reported on this table are

referred at the 12% CO

2

at the mean

sea level and with 0.1 mbar pressure

in the combustion chamber.

NOTE:

The values indicated in the table are purely

indicative; for best burner performance adjustment

needs to be made in accordance with the demands

of the particular boiler type.

RECOMMENDED NOZZLES

STEINES type ......... S 60°

MONARCH type ..... R 60°

DAN FOSS type ...... S 60°

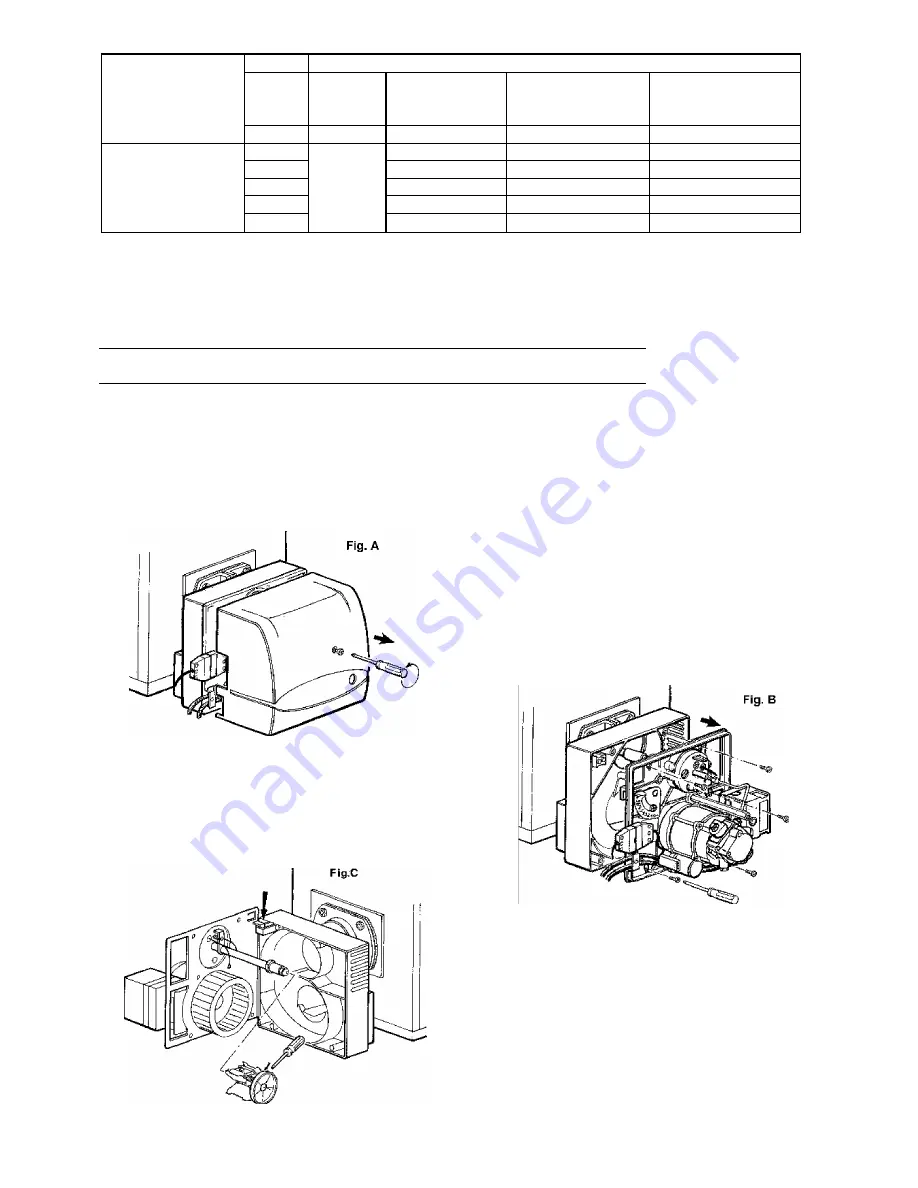

Most components can be inspected by removing the hood. To inspect the head you must disassemble the component-carrying

plate which can be hung on hung on the burner body in two different positions to make work as practical as possible. The

motor, transformer and solenoid valve are connected via a connector while the photo-resistor is push-locked into place.

MAINTENANCE

2) Undo the 4 screws of the plate, as indicated,

in order to access nozzle, electrodes and pre-

heater (if fitted).

1) Undo the lid screw to gain access to the

interior of the burner.

3) The plate must be hung up as illustrated in

fig. C.

- 12 -