30

GB

For the installation of sauna heaters, please

pay attention to the DIN VDE 0100 part 703 !

This standard makes the following statement

valid in your newest expenditure, since Februa-

ry 2006, paragraph 703.412.05; Quotation:

The additional must be planned for all electric

circuits of the Sauna by one or more fault current

protection device (RCDs) with a calculation diff e-

rence stream not more largely than 30 mA, exclu-

ded of it is Sauna heating.

The EN 60335-1 DIN VDE 0700 part 1 of Janu-

ary 2001 states the following in paragraph 13;

quote:

The leakage current may not exceed the following

values during operation:

- for stationary heaters of protection class I 0,75

mA; or 0,75 mA each kW input of the appliance,

depending on the higher value, at a maximum

value of 5 mA.

If the appliance is equipped with a protective

device for leakage current (ELCB), please pay at-

tention to the fact that no other electrical units

will be protected by this ELCB.

Under current manufacturing technology, it is

not reasonable to use heating elements for sau-

na heaters which do not collect moisture from

the surrounding air. It is therefore possible that

a little bit of moisture from the surrounding air

may reach the magnesium-oxide fi lling in the

heating elements during transport or storage

and may cause the ELCB to release.

In this case the oven must be heated up under

supervision of an expert, during which the PE

conductor is not connected. After about 10

minutes, when moisture has evaporated from

the heating elements, the oven must be recon-

nected to the PE conductor!

If the sauna heater is not in use for a signifi cant

period of time, we recommend running it every

6 weeks, so as to avoid moisture concentrating

in the heating elements.

Therefore, should the ELCB be released during

start-up, the electrical installation must be che-

cked.

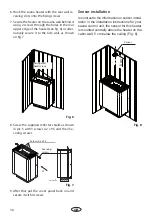

Installation of the sauna heater and control

unit must be undertaken only by an authorized

electrician.

Without a documented proof of

such installation a warranty is generally void.

Summary of Contents for Bi-O Filius

Page 2: ...2 Deutsch 3 English 20 o 37...

Page 16: ...16 D Auswechseln von Rohrheizk rpern 1 3 2 Abb 1 Abb 2 Abb 3 Abb 4 Abb 5...

Page 37: ...37 D Replacment of heating elements 1 3 2 Fig 1 Fig 2 Fig 3 Fig 4 Fig 5...

Page 45: ...34 RU DIN EN ISO 9001 2000 110 C 30 40 C 110 C 20 25 85 C 80 90 C...

Page 46: ...35 RU 8 VDE 0100 49 DA 6 VDE 0100 703 2006 2 5 10...

Page 47: ...36 RU DIN EN VDE 0100 T 703 40 170 C...

Page 48: ...37 RU S Guard...

Page 52: ...52 RU 4 3 4 4 2 5 2 2 3 3 3 3a 6 2 5 6 5 6 A Ansicht A 4 2 x 9 5 8 7 3 4 2 9 5...

Page 53: ...53 RU 5 7 5 cm 7...

Page 55: ...55 RU 4 3 4 4 2 5 5 2 2 3 3 3 3a 5...

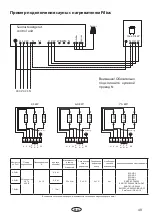

Page 56: ...56 RU A Ansicht A 5 6 5 cm 8 6 7 4 2 x 9 5 9 8 3 4 2 9 5 6 7 2 6 7...

Page 57: ...57 RU 1 3 2 1 2 3 4 5...

Page 58: ...58 RU 2 1 3 4 5 6 180 1 2 3 4 5 7 8 9 10 3 mm 2 1 6 28 3 mm 6 7...

Page 59: ...54 RU 4 5 5 1 0 8 4 II Ill 10...

Page 60: ...44 RU 100 10...

Page 62: ...46 RU RMA RMA RMA 3 1 2 2 RMA...