15

EN

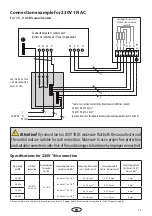

For the installation of sauna heaters, please

pay attention to the DIN VDE 0100 part 703 or

the corresponding national norms and legal

requirements, e.g. UL875 norm!

This standard makes the following statement

valid in your newest expenditure, since Febru-

ary 2006, paragraph 703.412.05; Quotation:

The addition must be planned for all electric cir-

cuits of the Sauna by one or more fault current

protection device (RCDs) with a calculation differ-

ence stream not more largely than 30 mA, exclud-

ed of it is Sauna heating.

The EN 60335-1 DIN (VDE 0700 part 1):2012-10

states the following in paragraph 13.2; quote:

The leakage current may not exceed the following

values during operation:

- for stationary heaters of protection class I 0,75

mA; or 0,75 mA each kW input of the appliance,

depending on the higher value, at a maximum

value of 5 mA.

If the appliance is equipped with a protective

device for leakage current (ELCB), please pay at-

tention to the fact that no other electrical units

will be protected by this ELCB.

Under current manufacturing technology, it is

not reasonable to use heating elements for sau-

na heaters which do not collect moisture from

the surrounding air. It is therefore possible that

a little bit of moisture from the surrounding air

may reach the magnesium-oxide filling in the

heating elements during transport or storage

and may cause the ELCB to release.

In this case the heater must be heated up un-

der supervision of an expert, during which

the Ground conductor is not connected. After

about 10 minutes, when moisture has evapo-

rated from the heating elements, the heater

must be reconnected to the Ground conductor!

If the sauna heater is not in use for a significant

period of time, we recommend running it every

6 weeks, so as to avoid moisture concentrating

in the heating elements.

Therefore, should the ELCB be released dur-

ing start-up, the electrical installation must be

checked.

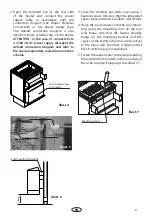

Installation of the sauna heater and control unit

must be undertaken only by an authorized and

appropriated qualified electrician.

Without a documented proof of such installa-

tion a warranty is generally void.