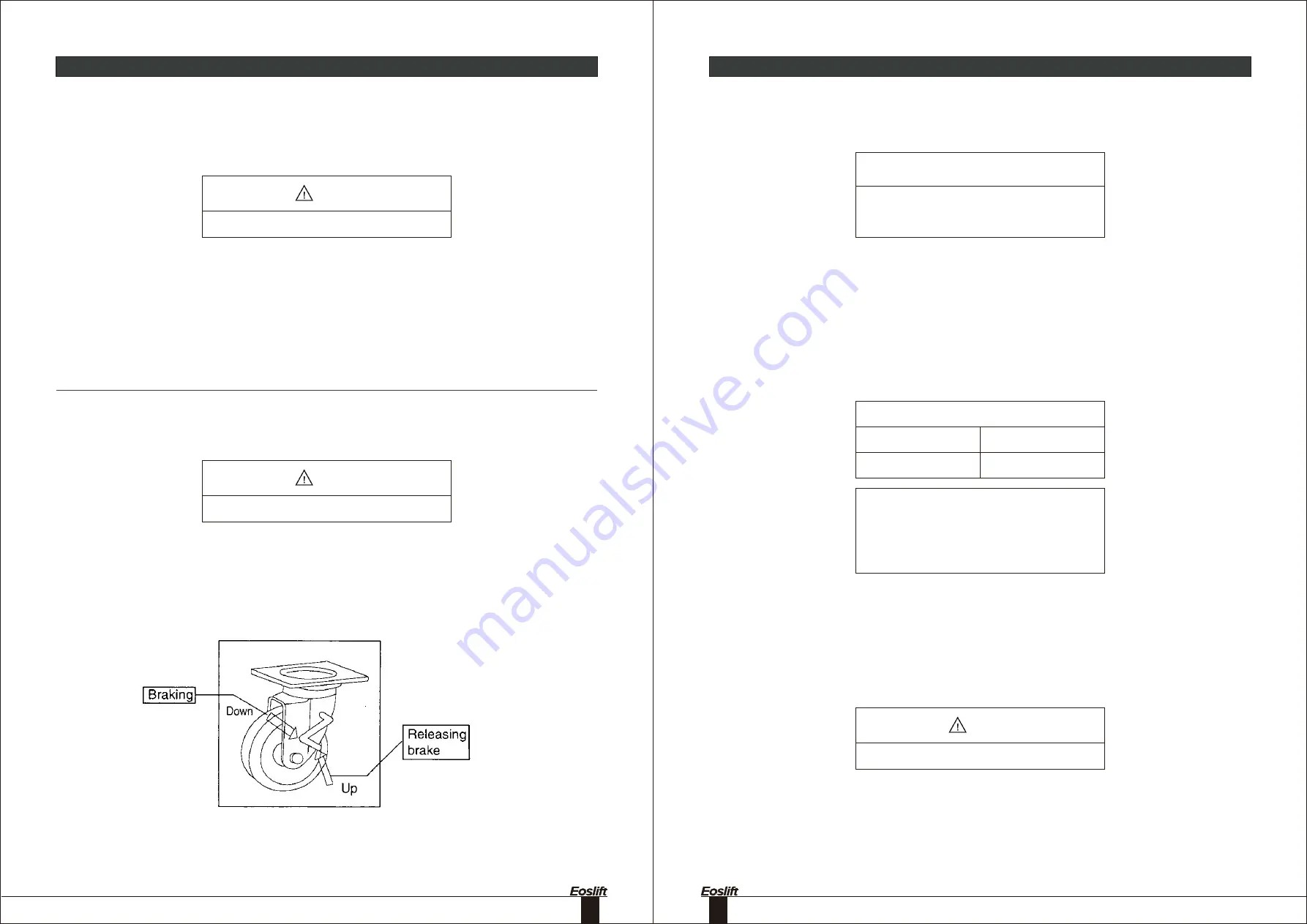

The brake is equipped with the swivel caster on the right side.

(1) Breaking the wheel, press the brake pedal.

(2) Releasing the brake, lift up the brake pedal.

4.

Daily Inspection

Daily inspection is effective to find the malfunction or fault on lift table.Check lift table on the following points

before operation.

(1) Check for scratch,bending or cracking on the lift table.

(2) Check if there is any oil leakage from the cylinder.

(3) Check the vertical creep of the table.

(4) Check the smooth movement of the wheels.

(5) Check the function of brake.

(6) Check if all the bolts and nuts are tightened firmly.

DO NOT use lift table if any malfunction or fault

is found.

CAUTION

5.

Operation Instruction

5-1. How to use the brake

Brake lift table when not moving it in order to

prevent sudden movement.

CAUTION

5-2. lifting the table

WARNINGS

1. DO NOT overload lift table. Stay within its

rated capacity.

2. DO NOT side or end load must be distributed

on at least 80% of table area.

Press the lifting pedal several times until the table reaches the desired position.

The table does not elevate after reaching the highest position even if the lifting pedal is pressed.

The table lowers slightly after reaching the highest position.

MAXIMUM CAPACITY OF TABLE

TAD35

350KG

TAD80

800KG

NOTE:

The hydraulic cylinder is designed to hold table.

As is the nature of the hydraulic system, table

lowers very slowly over and extended period of

time. Please note the table does not stay at the

same position

indefinitely.

5-3. Lowering table

WARNING

DO NOT put foot or hand in scissors mechanism

Pull the lowering lever up and table lowers.

2

3

5-4. Fold the handles

To fold the handle, push down the lock bar and lay

down the handle.