3 / GET STARTED

18 / XPS3

Elevation

Windage

Windage and Elevation

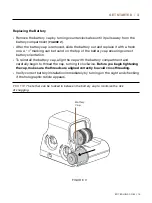

The HWS features subtle click mechanisms for elevation and windage adjustments

(

FIGURE 4

)

PRO TIP:

These adjustment mechanisms are grooved with a slotted screw head and require

the use of a screwdriver, coin, or spent brass to turn.

Adjustment Details

• For both elevation and windage, each click will change the sight’s point of aim

approximately 1/2 Minute of Angle (MOA), 1/4" (6 35mm) at 50 yards (45 7m),

or 1/2" (12 7mm) at 100 yards (91m) when zeroing

• Also, one full rotation of either knob will change the point of aim approximately

10 MOA, 5" (127mm) at 50 yards (45 7m), or 10" (254mm) at 100 yards (91m)

when zeroing

• To move the point of impact UP, turn the elevation adjustment LEFT

• To move the point of impact RIGHT, turn the windage adjustment RIGHT

The HWS elevation and windage adjustments are factory collimated with the bore of

the rifle parallel to the mounting rail The sight should be close to mechanical zero

when mounted on a properly installed rail Be sure to check that the mount and sight

are securely mounted after initial firing

CAUTION: When encountering an increase in resistance in adjustments, the end

of the adjustment range has been reached. DO NOT turn the adjustments any

farther as serious damage may occur to the sight.

FIGURE 4