REV. 03/2020

4

D

After operating for 1000 hours in total, the truck should also be maintained according to the

following procedures in addition to the 250-hour maintenance, 500-hour maintenance and 1000-

hour maintenance mentioned above

22

Inspect the running, lifting and lowering speed, braking distance and other

operation performances of the truck Inspect and add gearbox lubrication grease

24

Inspect where there is any damage in the oil cylinders and whether

corresponding installations are reliable

25L

Clean the oil tank and replace the hydraulic oil

26

Inspect and replace the hydraulic filter

27

Inspect whether the bearing capacity reaches the rated load and implement

corresponding adjustment through the flood valve adopted in the hydraulic

station

28

Inspect whether all the labels are clear and intact

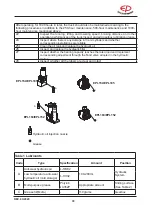

Table 1 Lubricants

Code

Type

Specification

Amount

Position

A

Anti-wear hydraulic oil

L-HM32

180-200mL

Hydraulic

System

Low temperature anti-wear

hydraulic oil (cold storage)

L-HV32

B

Multi-purpose grease

Polylub

GA352P

Appropriate amount

Sliding surface

(See Table 2)

C

Grease 3#(MoS

2

)

-

110 grams

Gearbox

A

A

C

C

EPL163/EPL152

EPL163/EPL152

EPL154/EPL185

EPL154/EPL185

Hydraulic oil injection nozzle

Grease

Summary of Contents for EPL152

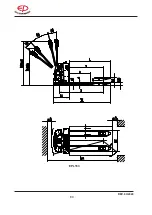

Page 50: ...REV 03 2020 9 E EPL163...

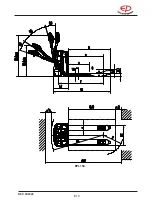

Page 51: ...REV 03 2020 10 E EPL154...

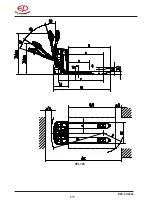

Page 55: ...REV 03 2020 14 E EPL152...

Page 56: ...REV 03 2020 15 E EPL185...