( 19 )

GB-6210 Manual

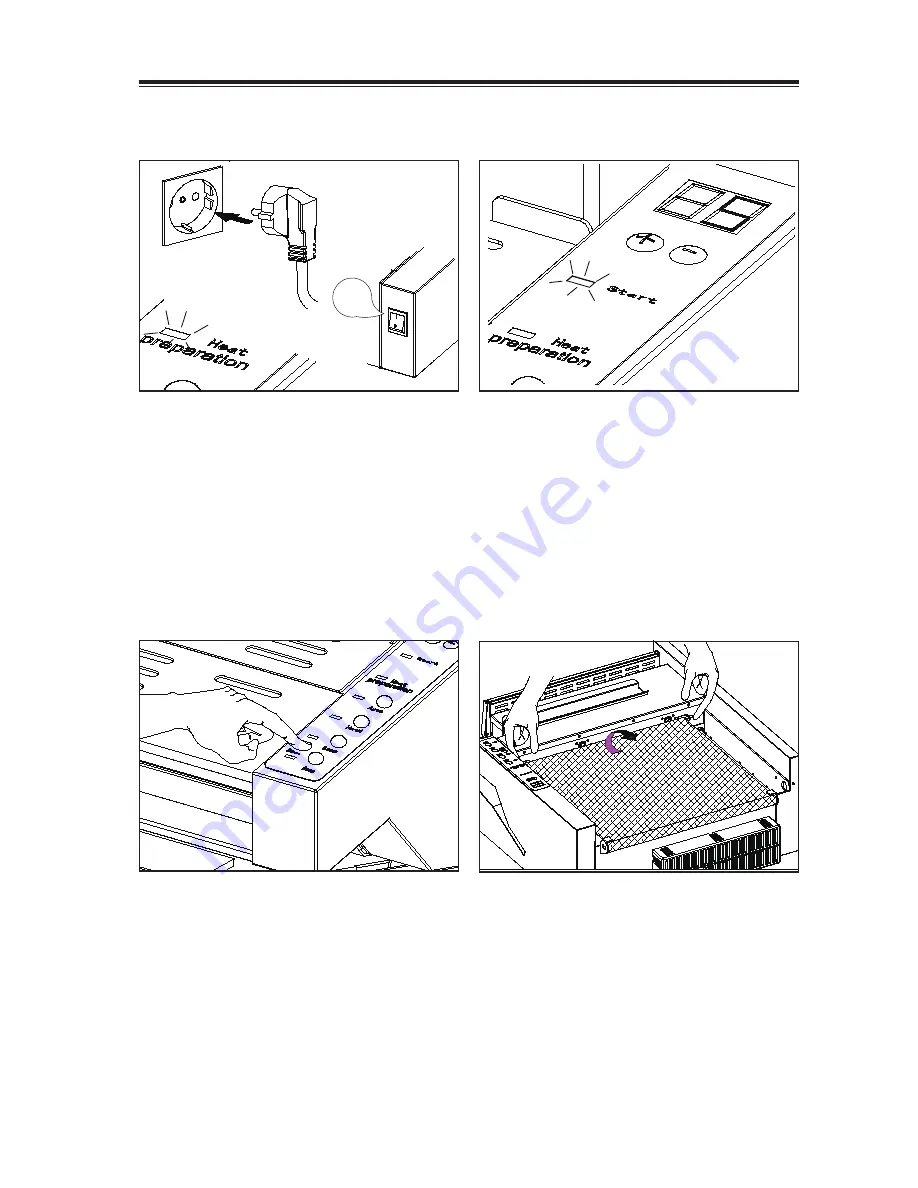

5-3-1 Turn on the machine

ON!

- Plug the power cord to outlet.

- Turn on the main switch.

- The Heat Preparation Lamp turns on, the

machine is heating the glue in the melt tank.

5-3-2 Melt glue

ON!

- Warming up time is about 20 minute.

- When Start lamp turns on, keep waiting 10

more minutes so that the glue in the melt tank

can fully melted.

5-3-3 Depress Reset Button

- Keep depressing Reset Button for about 5

seconds, the clamper will move forward and

stop at the front position above the nipper.

ON!

5-3-4 Remove the back cover

- Remove the back cover like above picture.

- Slowly get the back cover to the roller.