Rim-Drive Rotary Setup

The wheels on the left are the drive wheels which spin the cylinder. The wheels on the right are for support.

The right-side wheels are mounted on a scissor jack so they can be raised or lowered to level the top

surface of your cylinder with the X-beam. The scissor jack can be moved left and right to accommodate

cylinders of different lengths.

In most cases you will want to load your cylinder with the larger diameter on the left (drive wheel side).

The scissor jack is used to elevate the right side of your cylinder so that the top surface is horizontal. Load

your cylinder onto the Rotary Attachment so that it is just touching the black bumper. Using the clamp to

hold the glass in place is optional. Some odd shaped glasses rotate better if they are clamped to the

drive wheels, but most glasses and other cylindrical objects do not require clamping.

Use the scissor jack to raise the right side of the cylinder so that the engraving/cutting surface is

horizontal. The photos below show the same flashlight at a severe angle to horizontal. If your cylinder is

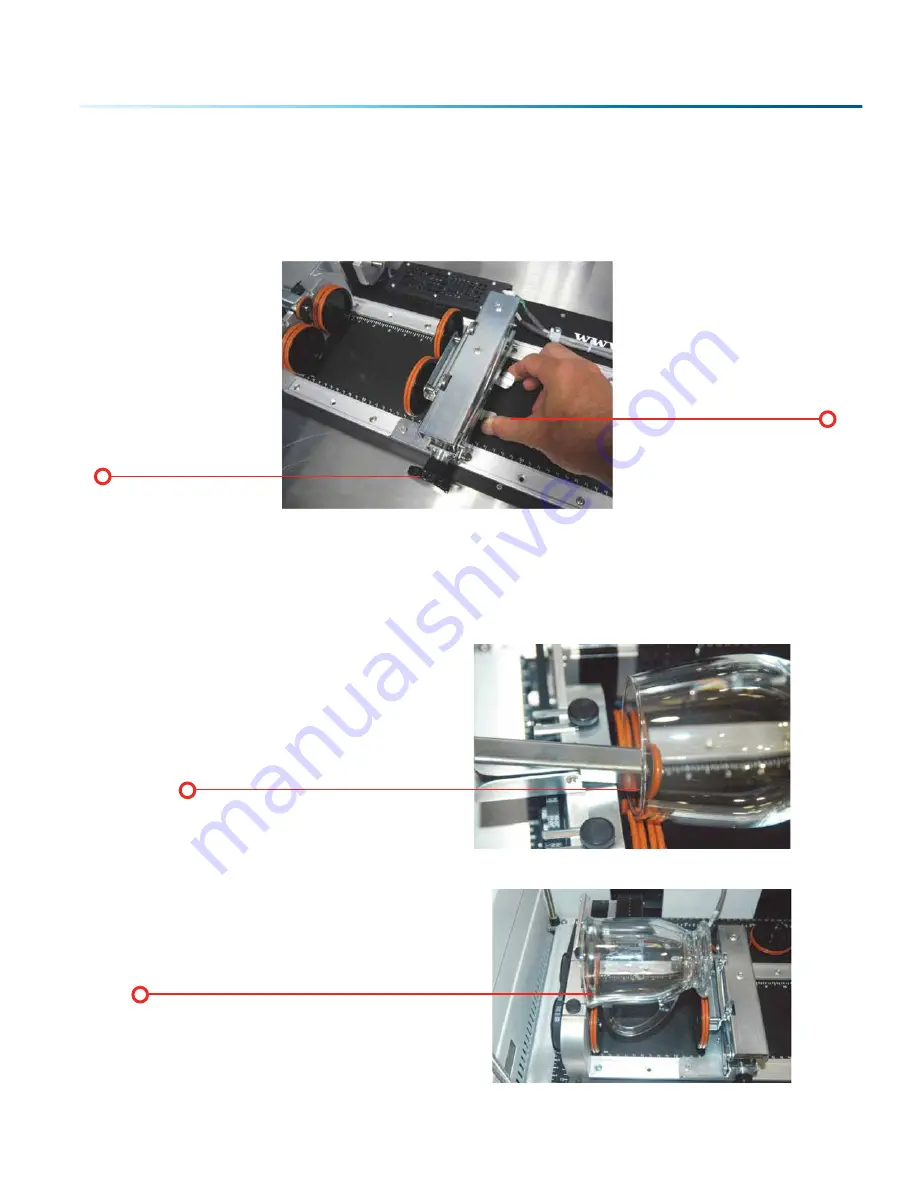

Rotate the knob to lift

or lower the scissor

jack.

Squeeze the tabs to move

the scissor jack left and

right.

This photo shows the clamp holding

a glass against the drive wheels.

Use the thumbscrews to adjust the

clamp in and out.

Many glasses, like this one, do not require

the use of the clamp. The clamp is used

mostly for hard to rotate cylinders or very

lightweight objects that need more than just

gravity to hold them in place.

- 129 -

SECTION 9: OPTIONAL FEATURES

Summary of Contents for Fusion Pro 32

Page 2: ......

Page 6: ......

Page 14: ...Fusion Pro 48 8 SECTION 1 SAFETY ...

Page 15: ... 9 SECTION 1 SAFETY ...

Page 18: ......

Page 28: ......

Page 60: ......

Page 98: ......

Page 108: ......

Page 132: ......

Page 162: ......

Page 184: ......

Page 202: ......

Page 214: ......

Page 216: ......

Page 242: ......