Owner's Manual for EPILOG Legend Model 6000

December, 2000

Section 6 – Using The Epilog Legend

33

demanding graphics should be run using the factory settings. Large block lettering or less

demanding images can be run at values of 9 or 10 to increase production speeds.

i.

This parameter is set at the factory at a setting of 5 and normally does not need to be

changed.

ii.

This adjustment can be made “on the fly” while the Legend is engraving.

iii.

Select “SERVICE”, then “CALIBRATE”, then “ACCELERATION

COMPENSATION”.

iv.

Using the “JOG SHUTTLE KNOB”, change the setting, then press the “ENTER”

key. The acceleration will change immediately and stay at the new value until you

reboot or power down your Legend.

v.

If you wish to save your settings go to “OPTIONS” on the LCD panel then “SAVE

SETTINGS” to permanently save the new settings.

vi.

Failure to “SAVE SETTINGS” will result in the laser returning to the default settings

the next time that you power down the Legend.

While this feature can affect engraving times, it is not the recommended method of adjusting

engraving speed. Normally you would adjust the engraving speed either from the print driver

or from the “SETUP” menu on the LCD.

h.

Ramp Compensation: “RAMP COMPENSATION” controls the distance of over-shoot that

the carriage has when it gets to the end of each engraving line. The Ramp Compensation

counter has a numeric range from 0 (zero) to 10. The higher the number (10), the greater the

distance that the carriage will over-shoot. Higher numbers will increase the amount of time

that it takes to complete a job. Depending on the type of image that you are producing, the

“RAMP COMPENSATION” can be adjusted to provide the best combination of quality and

speed. Fine details or demanding graphics should be run using the factory settings. Large

block lettering or less demanding images can be run at values of 1 or 2 to increase production

speeds.

i.

This parameter is set at the factory at a setting of 5 and normally does not need to be

changed.

ii.

This adjustment can be made “on the fly” while the Legend is engraving.

iii.

Select “SERVICE”, then “CALIBRATE”, then “RAMP COMPENSATION”.

iv.

Using the “JOG SHUTTLE KNOB”, change the setting, then press the “ENTER”

key.

v.

The acceleration will change immediately and stay at the new value until you reboot

or power down your Legend.

vi.

If you wish to save your settings go to “OPTIONS” on the LCD panel then “SAVE

SETTINGS” to permanently save the new settings.

vii.

Failure to “SAVE SETTINGS” will result in the laser returning to the default settings

the next time that you power down the Legend.

3.

Vector Test: Not enabled. Reserved for future use.

4.

Raster Test: Not enabled. Reserved for future use.

5.

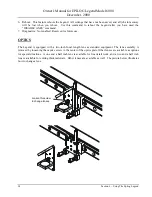

Disable Axes: This feature allows you to disable the electrical current to the X and Y axis motors.

Disabling the current allows you to move the carriage freely by hand to any point on the

engraving/cutting surface. Disabling the axes provides a means to quickly focus on an uneven surface in

either standard engraving mode or it is particularly helpful for focusing when using the Rotary

Attachment.

a.

In the “SERVICE” menu highlight “DISABLE AXES”. Press “ENTER”. You are now able

to move the carriage freely without any resistance from the motors.

b.

Pressing “REBOOT” is the only way to re-enable the axes.