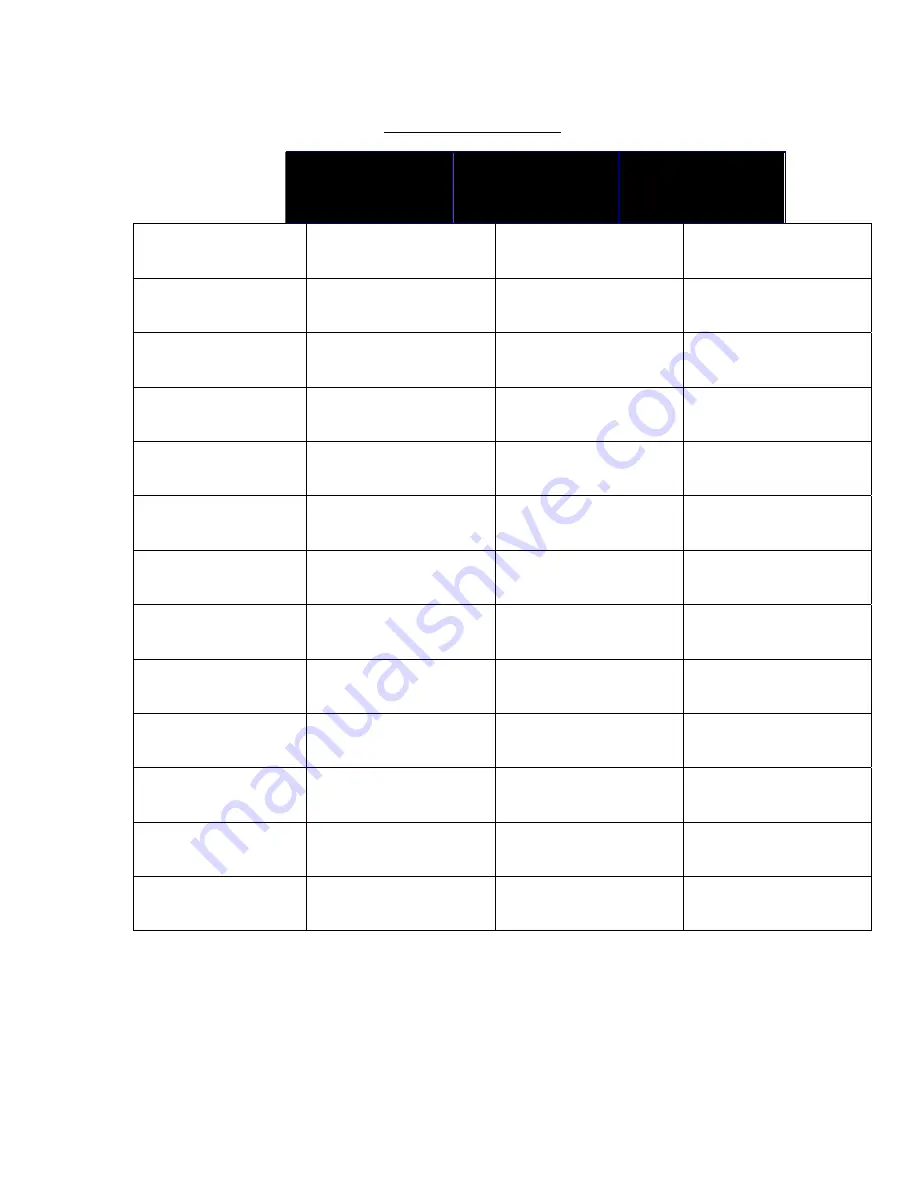

30 WATT RADIUS

300 DPI ENGRAVING

SPEED-POWER

600 DPI ENGRAVING

SPEED-POWER

CUTTING

SPEED-POWER

1/4" Wood

25-100 35-100 5-100

1/4" Acrylic

25-100 100-15 5-100

Anodized Aluminum

100-60 100-40 N/A

Brass-Painted

100-55 100-40 N/A

Corian Or Avonite

25-100 25-100 N/A

Delrin

30-100 35-100 15-100

Glass

45-100 50-100 N/A

Laserable Plastic

100-65 100-55 18-50

Leather

100-65 100-55 N/A

Marble

35-100 35-100 N/A

Matboard

100-65 100-65 20-75

Melamine

45-100 65-100 N/A

Rubber Stamps

18-100 20-95 10-100

26