16

epoke

®

SKE8-12-15-20

GB-0305.1

Date:

Signed:

1 Flanged bearings:

At the delivery roller and

the impellor shaft

Ball bearing grease

25 h

2 Tallow string packing:

At the delivery roller and

the impellor shaft

25 h

***

3 Delivery roller:

Cams

50 h

Visual inspection. Worn

cams to be replaced.

4 Impellor springs

50 h

Worn springs to be replaced

5 Rubber bases

50 h

The rubber bases are wed-

ged in under the clamping

iron and can be turned and

worn on all edges - provided

that they are turned in time.

6 Spring base

50 h

Visual inspection. When

the spring base is wide

open, the points of the

springs must be in line.

Worn springs to be replaced

7 Chain transmission:

Roller chains

50 h

Check that the chains are

tight. The chains must not,

however, be firmly tightened.

Rolling chain - lubrication

Wynn's Viscotene

50 h

Silicone spray grease

8 Wheel nuts

*140 Nm (14,0 kpm)

50 h

*Tightening moment

9 Air pressure

see tyre list

50 h

10 Spring base adjustment

Grease

100 h

***

The tallow string packing consists of a rubber collar in which the tallow string of 2 1/2 windings is pressed in between

flange bearing and covering plate. When the flange bearing is mounted, the space between tallow string and flange

bearing is filled withe grease, which supports the tightening effect of the tallow string. Lubrication is carried out with

intervals of 25 hours of operation. If the grease penetrates into the hopper through the tallow string packing when lubrica-

ting, the tallow string should be replaced.

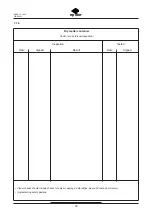

To be checked

Pos.

Machine:

Inspection list - mechanical

Measure size

and test size.

Operational

means and con-

sumption means

Interval

Result of

inspection

Comment

6.3.1

.

Summary of Contents for SKE Series

Page 2: ......

Page 10: ......

Page 12: ...9 epoke SKE8 12 15 20 GB 0305 1 2 2 4 6 7 8 9 10 1 2 3 4 5 C B A C D...