Page 50

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

ELR 9000 Series

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

3.5.3.2 General information about the interface modules

With the standard models of series ELR 9000, one of the plug-in and retrofittable modules listed in

be installed. It can take over remote control of the device alternatively to the built-in USB type B on the back side

or the analog interface. For installation see section

„1.9.8. Interface module slot“

and separate documentation.

The modules require little or no settings for operation and can be directly used with their default configuration.

All specific settings will be permanently stored such that, after changeover between the various models, no re-

configuration will be necessary.

3.5.3.3 Programming

Programming details for the interfaces, the communication protocols etc. are to be found in the documentation

“Programming Guide ModBus & SCPI“ which is supplied on the included CD or which is available as download

from the EPS Stromversorgung website.

3.5.4 Remote control via the analog interface (AI)

3.5.4.1 General

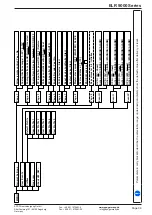

The built-in, galvanically separated, 15-pole analog interface (short: AI) is on the back side of the device offers the

following possibilities:

•

Remote control of current, voltage, power and resistance *

•

Remote status monitoring (CC/CP, CV)

•

Remote alarm monitoring (OT, OVP)

•

Remote monitoring of actual values

•

Remote on/off switching of the DC input

Setting the

three

set values for voltage, current and powerr via the analog interface always takes place

concur-

rently

. It means, that for example the voltage can not be given via the AI and current and power set by the rotary

knobs, or vice versa. Resistance mode is additionally possible and requires to set the corresponding pin.

The OVP set value and other supervision (events) and alarm thresholds cannot be set via the AI and therefore

must be adapted to the given situation before the AI is put in operation. Analog set values can be fed in by an ex-

ternal voltage or generated by the reference voltage on pin 3. As soon as remote control via the analog interface

is activated, the values displayed will be those provided by the interface.

The AI can be operated in the common voltage ranges 0...5 V and 0...10 V in each case 0...100% of the nominal

value. The selection of the voltage range can be done in the device setup. See section

for details

.

The reference voltage sent out from Pin 3 (VREF) will be adapted accordingly and is then:

0-5 V

: Reference voltage = 5 V, 0...5 V set values (VSEL, CSEL, PSEL, RSEL) correspond to 0...100% nominal

values, 0...100% actual values correspond to 0...5 V at the actual value outputs (CMON, VMON).

0-10 V

: .Reference voltage = 10 V, 0...10 V set values (VSEL, CSEL, PSEL, RSEL) correspond to 0...100% nominal

values, 0...100% actual values correspond to 0...10 V at the actual value outputs (CMON, VMON).

Input of excess set values (e.g. >5 V in selected 5 V range or >10 V in the 10 V range) are clipped by setting the

set value at 100%.

Before you begin, please read. Important notes for use of the interface:

•

Analog remote control of the device must be activated by switching pin “REMOTE” (5) first. Only exception is

pin REM-SB, which can be used independently since KE firmware version 2.07

•

Before the hardware is connected that will control the analog interface, it shall be checked that it can’t provide

voltage to the pins higher than specified

•

Set value inputs, such as VSEL, CSEL, PSEL and RSEL (if R mode is activated), must not be left unconnected

(i.e. floating)

•

It is always required to provide all three set values at once. In case any of the set values is not used for adjust-

ment, it can be tied to a defined level or connected to pin VREF (solder bridge or different), so it gives 100%

The analog interface is galvanically isolated from DC input. Therefore do not connect any

ground of the analog interface to the DC- or DC+ input!

* Unless the device has not already been delivered with KE firmware version 2.10 or higher, using the RSEL input requires retrofitting in the factory