EPSON Stylus PHOTO 2100/2200

Revision B

PRODUCTION DESCRIPTION

Casing Specifications

37

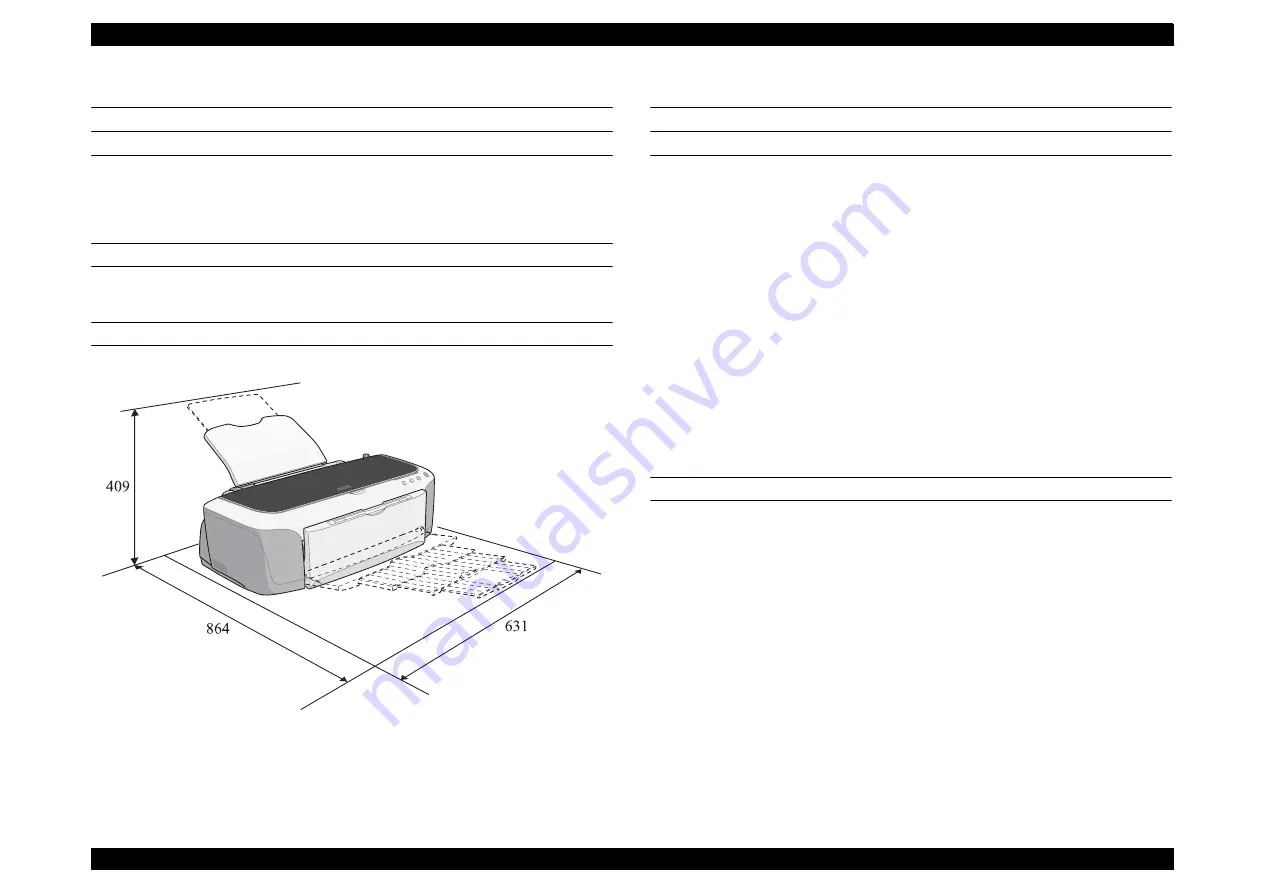

1.4 Casing Specifications

EXTERNAL DIMENSIONS

When tucked

: 631 (width)

×

320 (depth)

×

205 mm (height)

When used

: 631 (width)

×

864 (depth)

×

409 mm (height)

WEIGHT

11.7kg

EXTERNAL DIMENSION DIAGRAM

Figure 1-15. External Dimension Diagram

1.5 Accessories

STANDARD ACCESSORIES

!

Instruction manual

: 1 set

!

Ink cartridge

: 1 set

!

CD-ROM (Printer driver utility)

: 1 set

!

Roll paper holder

: 1 set

!

Sheet

: 1 pc.

!

Customer information card

: 1 pc.

!

Warranty:

: 1 pc.

!

Free exclusive paper pack

: 1 set

!

CD-R tray guide

: 1 pc.

!

CD-R tray

: 1 pc.

!

Cleaning kit

: 1 set

CONSUMABLES AND OPTIONS

!

Ink cartridges

Photo-black

: T0341

Cyan

: T0342

Magenta

: T0343

Yellow

: T0344

Light cyan

: T0345

Light magenta

: T0346

Light-black

: T0347

Matte-black

: T0348

!

Roll paper auto cutter

(Cutter, paper support basket, instruction manual): PMA3NRAC1

!

Ink cartridge storage box

: PMICBOX1

!

USB cable

: USBCB2

Summary of Contents for 2200 - Stylus Photo Color Inkjet Printer

Page 1: ...EPSONStylusPHOTO2100 2200 Color Inkjet Printer SEIJ01 016 SERVICE MANUAL ...

Page 8: ...C H A P T E R 1 PRODUCTIONDESCRIPTION ...

Page 39: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 69: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 115: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 187: ...C H A P T E R 5 ADJUSTMENT ...

Page 214: ...C H A P T E R 6 MAINTENANCE ...

Page 226: ...C H A P T E R 7 APPENDIX ...

Page 254: ......

Page 255: ......

Page 256: ......

Page 257: ......

Page 258: ......