A-18

Enhancing Your Printer With Options

R4C4620

Rev. C

A5 size

OPTIONS.FM

6/14/00

Pass 3

L

Proof Sign-off:

SEI

Y.Ohkawara T.Takahashi

T.Takahashi

SEI

M.Kauppi K.Blair

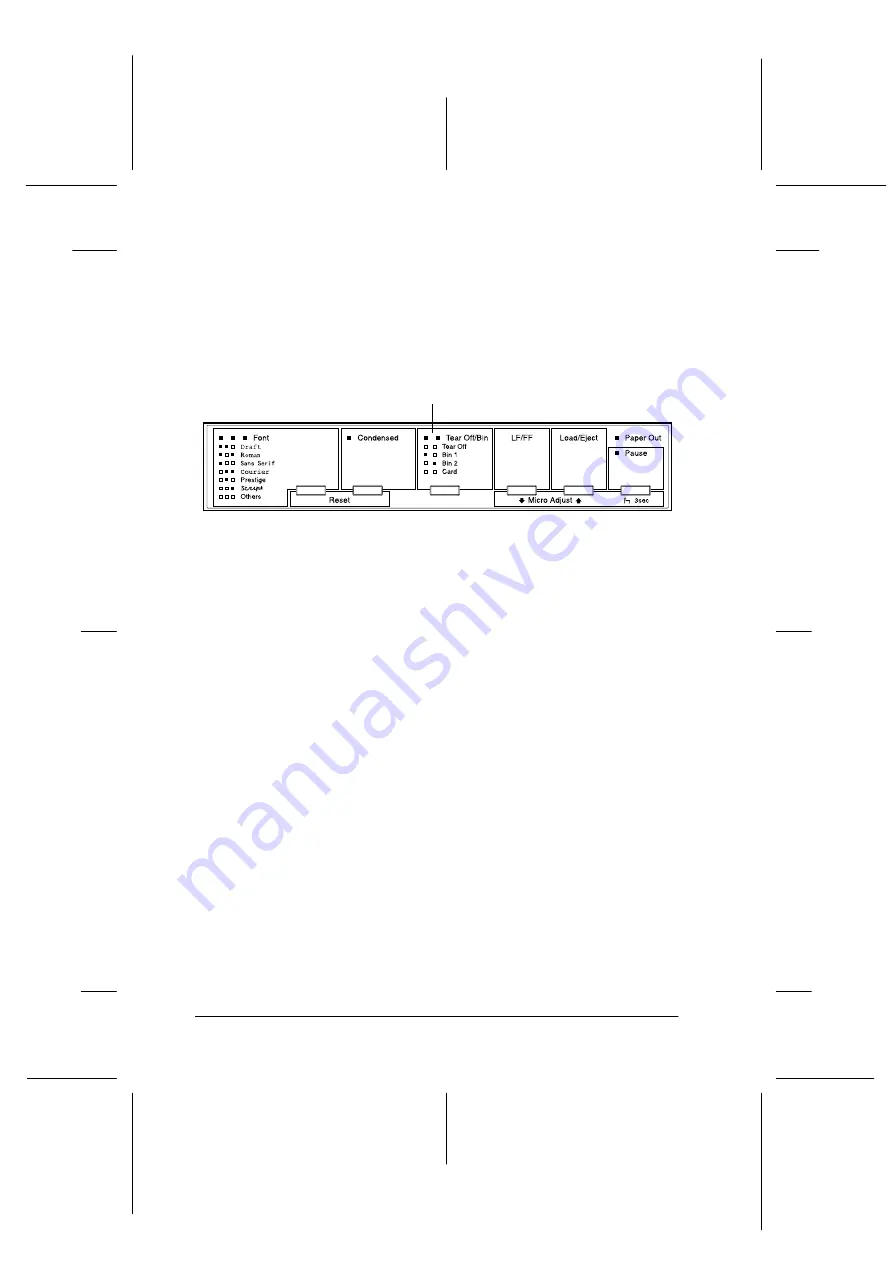

It is best to select the paper path in your application program

because software settings usually override the printer’s control

panel settings. However, if you cannot select the paper path in

your application, select a path by pressing the Tear off/Bin button

until the light indicates the bin you want as shown below.

The cut-sheet feeder you selected automatically loads paper when

the printer receives data.

Switching between continuous paper and single-sheet

paper in the cut-sheet feeder

You can easily switch between continuous paper on a push tractor

and single-sheet paper in the cut-sheet feeder without removing

the continuous paper.

Switching to continuous paper

1. If any sheets are in the paper path, press the

Load/Eject

button to eject them.

2. Move the printer’s paper release lever to the push tractor

position. Also set the paper thickness lever to the proper

position for your paper.

■ ❑

: bin 1 (high-capacity cut-sheet feeder) is selected.

❑

■

: bin 2 (single-bin cut-sheet feeder) is selected.