Epson Stylus Photo R280/R285/R290/Epson Artisan 50/Epson Stylus Photo T50/T59/T60/P50

Revision C

Chapter 5 Adjustment

5.2 Using the Adjustment Program

114

Confidential

Adjustment procedure

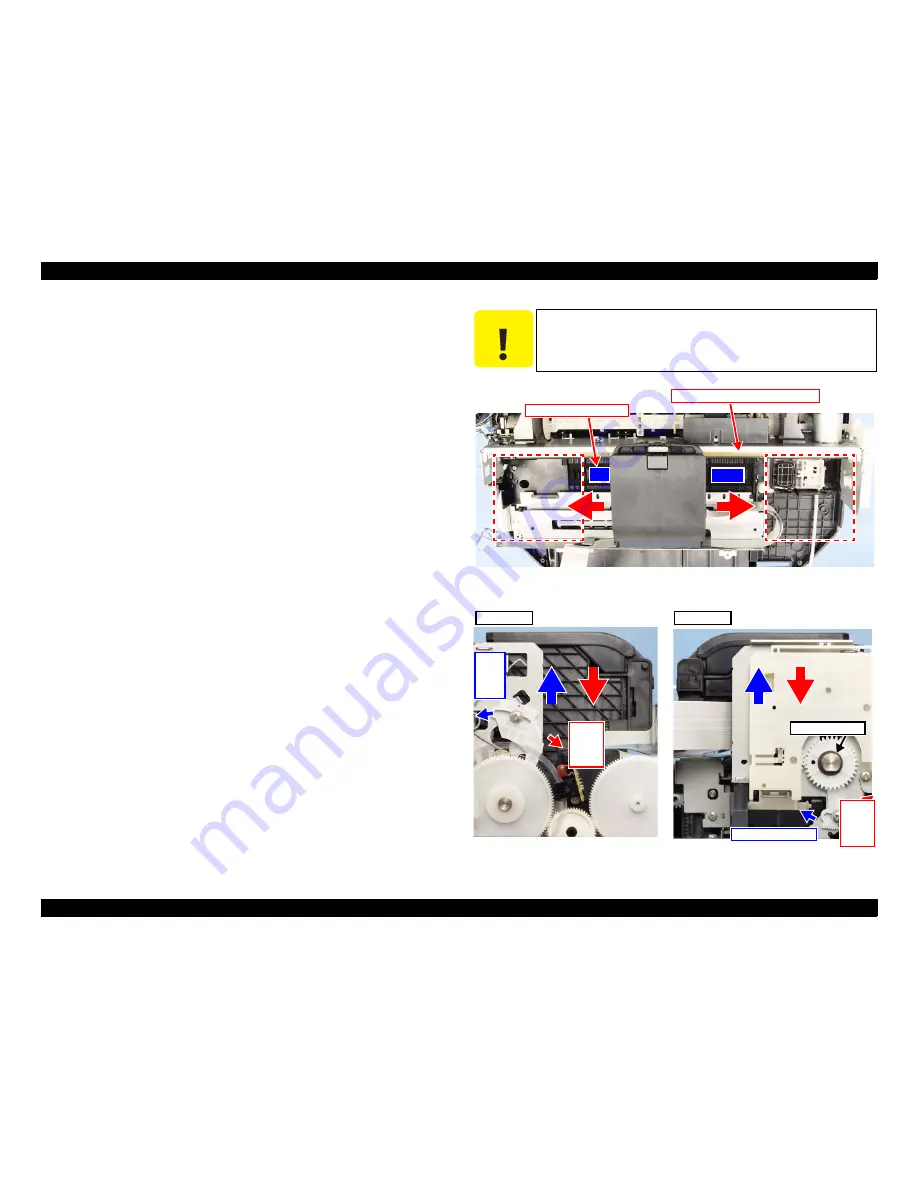

Specified PG value: 1.2 ± 0.1 mm

1. Install new ink cartridges in the carriage.

2. Remove the Cable Holder Frame.

(Fig. 4-73)

3. Check that the APG Assy and the carriage are in the PG-position.

(Fig. 5-8)

4. Move the carriage to the center of the platen, and place 1.15 mm thickness gauge

on the left aligning its left edge with the second rib of the Front Paper Guide. And

place another 1.15 mm thickness gauge on the right aligning its right edge with the

rightmost rib of the Front Paper Guide.

(Fig. 5-9)

NOTE:

The thickness gauge must not be set over the leftmost rib on the Front

Paper Guide.

5. Pull the Timing Belt to move the carriage to the left end.

6. If the carriage comes in contact with the gauge, adjust the Left Parallelism Bush to

raise the carriage to a position where the Printhead does not come in contact with

gauge.

7. Pull the Timing Belt to move the carriage to the right end.

8. If the carriage comes in contact with the gauge, adjust the Right Parallelism Bush

to raise the carriage to a position where the Printhead does not come in contact

with gauge.

9. Move the carriage to the middle area of the platen, and place 1.3 mm thickness

gauges at the left and right ends of the platen.

10. Pull the Timing Belt to move the carriage to the left end.

11. If the carriage does not come in contact with the gauge, make the adjustment

again.

12. Pull the Timing Belt to move the carriage to the right end.

13. If the carriage does not come in contact with the gauge, make the adjustment

again.

14. Mark the indicated graduation position of the right and left Parallelism Bush, and

tighten the screws.

(Screw tightening torque: 0.8±0.1 N•m)

Figure 5-9. PG Adjustment 1

Figure 5-10. PG Adjustment 2

C A U T I O N

The Printhead must come in contact with the 1.3 mm thickness

gauges but must not come in contact with the 1.15 mm thickness

gauges.

Gauge (1.15 or 1.3mm)

Pull the belt to move the carriage

CR Guide Shaft

CR Guide Shaft UP

CR

Guide

Shaft

DOWN

CR

Guide

Shaft

UP

CR

Guide

Shaft

DOWN

~Left side~

~Right side~

Summary of Contents for 50 - Artisan 50 - Printer

Page 8: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 22: ...Confidential C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 29: ...Confidential C H A P T E R 3 TROUBLESHOOTING ...

Page 52: ...Confidential C H A P T E R 4 DISASSEMBLY ASSEMBLY ...

Page 103: ...Confidential C H A P T E R 5 ADJUSTMENT ...

Page 120: ...Confidential C H A P T E R 6 MAINTENANCE ...