EPSON LQ-570e

2 -

EPSON LQ-570e

4/00

Optional Interface Cards

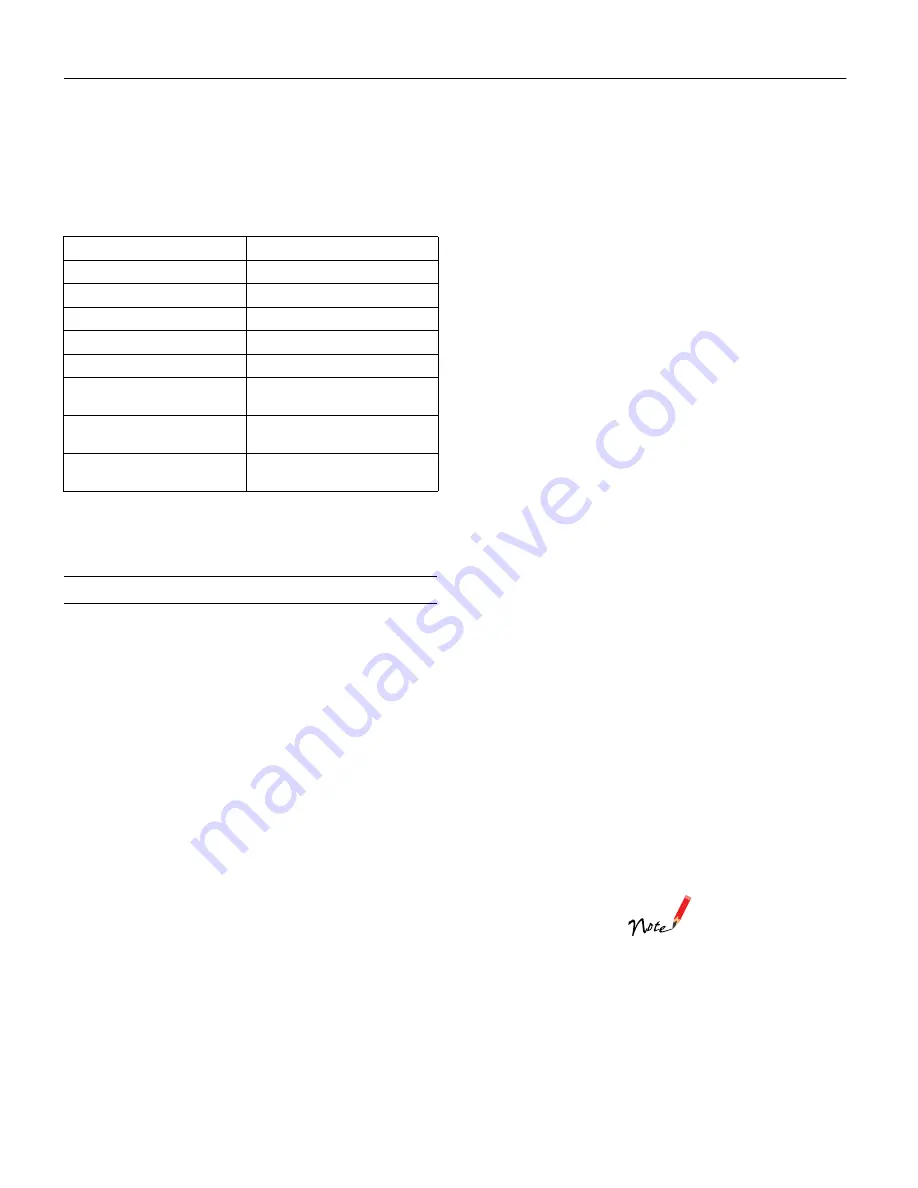

You can install an optional interface card to supplement your

printer’s built-in parallel interface and provide added network

compatibility. The EPSON interface cards in the table below

are compatible with your printer.

* If you install the C823051 optional serial interface card, be sure to

set the transfer speed to one of the following: 300, 600, 1200, 2400,

4800, 9600, or 19200 bps.

Printer Specifications

Mechanical

Model number

Card type

C823051

Serial Type B interface card

C823071

32KB serial Type B interface card

C823121

LocalTalk interface card

C823141

Coax Type B interface card

C823151

Twinax Type B interface card

C823451

IEEE-1284 (Type B bidirectional)

parallel interface card

C823622

Type B Ethernet interface card for

10 Base 2 / 10 Base T

C823642

Type B Ethernet interface card for

10/100 Base TX with AC adapter

Printing method

24-pin impact dot matrix

Emulation

EPSON ESC/P

®

2 and IBM 2390 Plus

Printing speed

High-speed draft

400 cps at 10 cpi

Draft

300 cps at 10 cpi

360 cps at 12 cpi

450 cps at 15 cpi

Draft condensed

257 cps at 17 cpi

300 cps at 20 cpi

LQ

100 cps at 10 cpi

120 cps at 12 cpi

150 cps at 15 cpi

LQ condensed

171 cps at 17 cpi

200 cps at 20 cpi

Printing direction

Bidirectional logic seeking for text and

graphics printing. Unidirectional text

or graphics printing can be selected

using software commands.

Line spacing

1/6 inch or programmable in

1/360-inch increments

Printable columns

80 columns (at 10 cpi)

Resolution (maximum) Letter quality: 360

×

180 dpi

Raster graphics: 360

× 360

dpi

Interfaces

1 standard bidirectional, 8-bit parallel

interface with IEEE-1284 nibble mode

support, and 1 optional interface slot

Paper feed methods

Friction (front or top paper entry)

Push tractor (rear paper entry)

Pull tractor (front, bottom, or rear

paper entry)

Push and pull tractor (optional)

High-capacity cut-sheet feeder

(optional)

Roll paper holder (optional)

Paper feed speed

Continuous

5 inches/second

Intermittent

45 ms/line at 1/6-inch line spacing

Paper capacity

Optional high-capacity cut-sheet feeder

up to 150 sheets of 22 lb (82 g/m

2

)

paper

up to 25 plain or bond envelopes

up to 30 airmail envelopes

up to 30 postcards

Single-bin cut-sheet feeder

up to 50 sheets of 22 lb (82 g/m

2

)

paper

The total thickness of the

paper stack can be up to

0.20 inch (5 mm).

Buffer

64KB