/Action Laser

Service Manual

Operating Principles

2.1.2.5 Laser

Diode

Drive

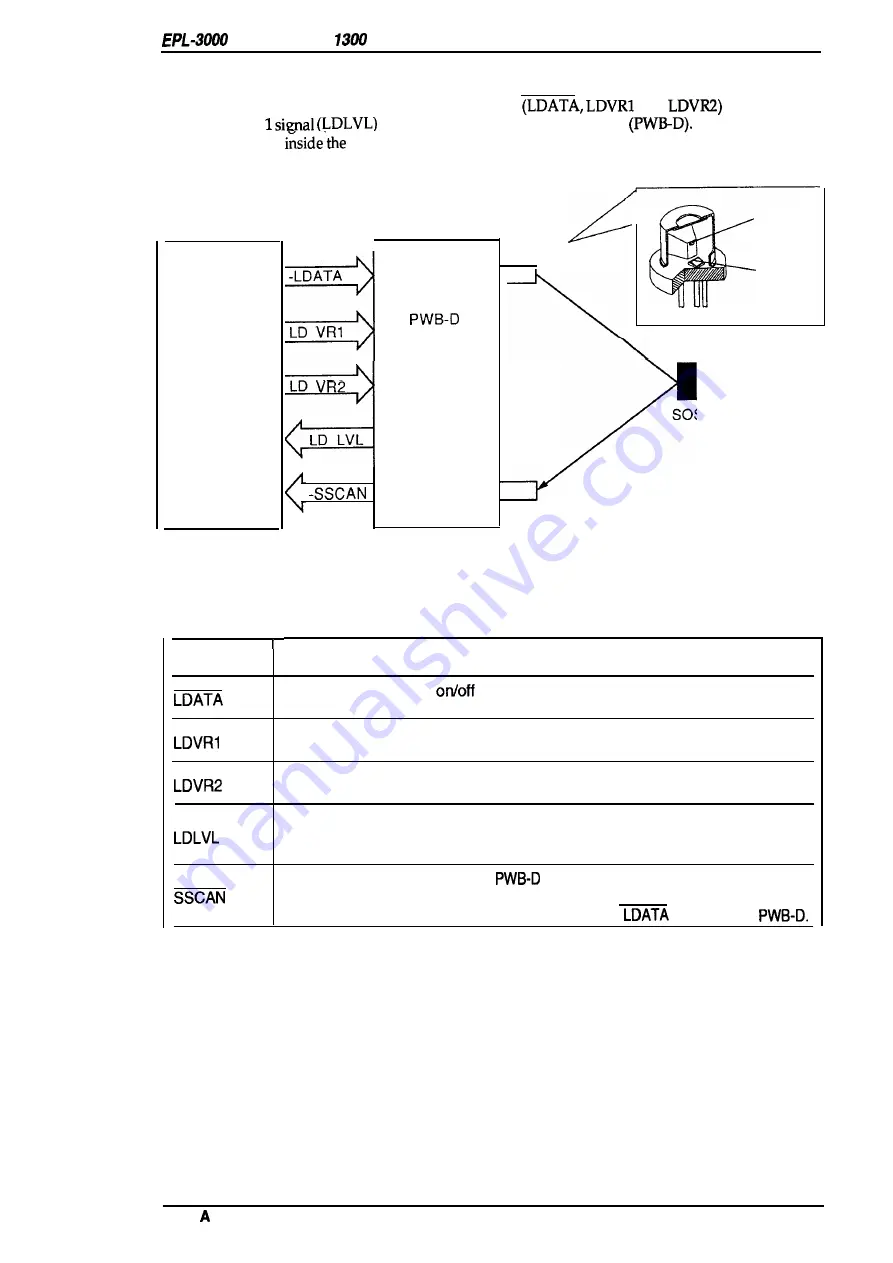

Laser diode emission is controlled by three signals

and

sent from the

main board a

from the laser diode drive board

The photo diode

(sensor) is located

laser diode. This sensor measures the laser power.

Controller

Board

-LDATA

LD

LD

Laser Diode

Drive Board

LD LVL

Laser Diode

Laser

Diode

Photo

Diode

SOS Mirror

SOS Sensor

Figure 2-22. Laser Diode Drive Circuit

Table 2-2. Laser Diode Control Circuit

Signal

Description

This signal is the laser

signal. When it is “L”, the laser is allowed to emit;

and

when it is “H”, the laser is stopped emitting.

This signal adjusts the laser drive current so that the laser emission becomes

the regulated value (rough adjustment).

This signal adjusts the laser drive current so that the laser emission becomes

the regulated value (fine adjustment).

This signal indicates whether the laser drive current has reached the regulated

value. The signal “H” shows that the current has reached the regulated value

and the signal “L” shows that the current has not yet.

This signal is returned from the

to the main board. This is the signal to

the SOS sensor and is the main scanning direction synchronization signal. The

main board is timed with this signal and sends the

signal to the

Rev.

2-15