EPSON AcuLaser C4000/C4100/C3000

Revision F

Appendix

Wiring Diagrams and Signal Information

9-651

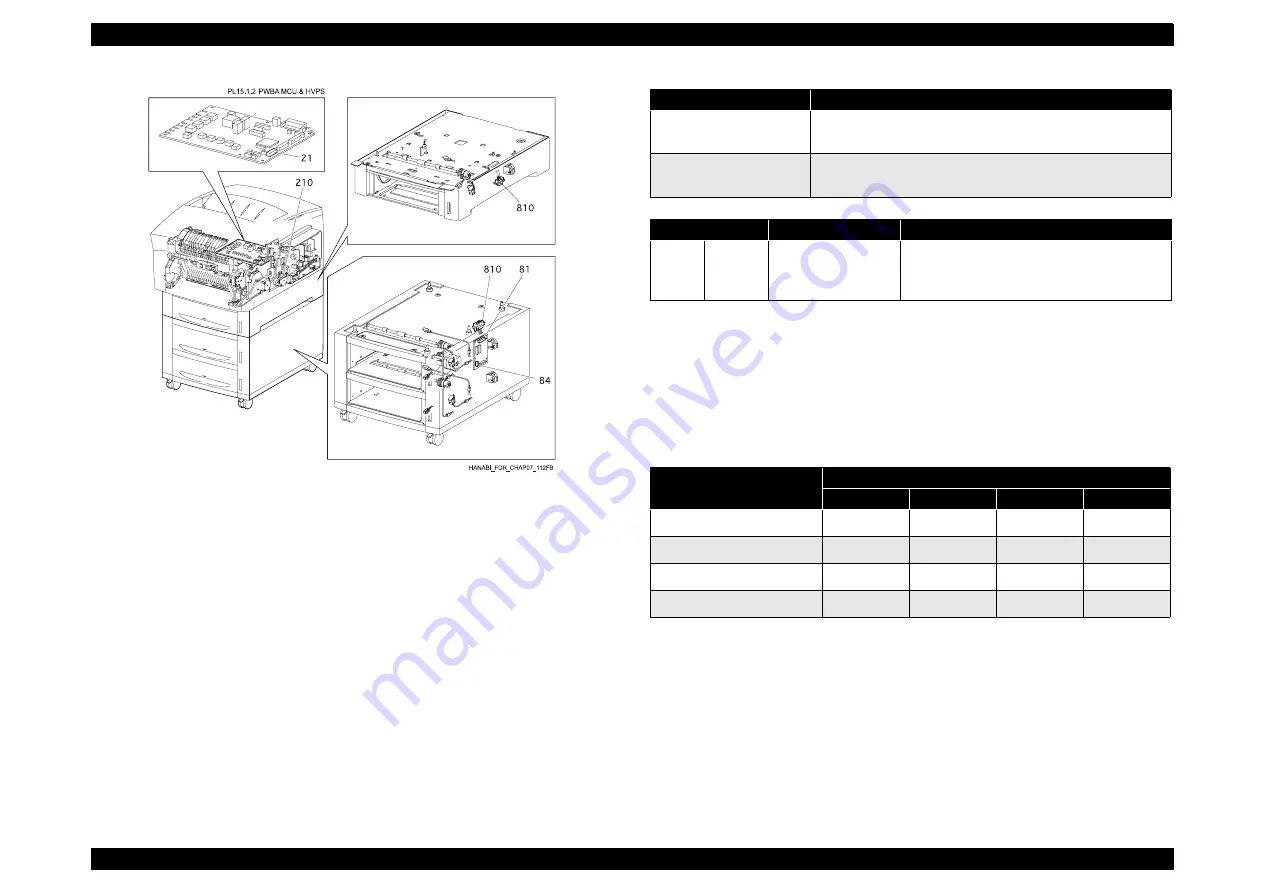

Description of DRIVE ASSY DEVE (PL14.1.1).

Motor type: Hybrid type stepping motor

Step angle: 1.8° ± 0.09°

Winding resistance: TBD

Ω

± 10% / Phase (25°C)

Excitation sequence : See the following table. (*: excitation)

Signal line

Description

FDR A, FDR B, FDR XA,

FDR XB, DA_FDRMOT

Drive Control Signal for DRIVE ASSY FEEDER

(PL17.4.5).

FDR_A, FDR_B,

FDR_XA, FDR_XB

Excitation signal for DRIVE ASSY FEEDER (PL17.4.5).

P/J No.

Signal line

Description

P21-24 P210-A3 NO OPF(L)+3.3VDC

Installation Sensing Signal for OPTION

FEEDER.

(High: Installed. Low: Not Installed.)

Phase

Step (2-phase excitation)

1

2

3

4

DEVE_A

*

*

DEVE_B

*

*

DEVE_XA

*

*

DEVE_XB

*

*

Summary of Contents for AcuLaser C3000 Series

Page 20: ...C H A P T E R 1 PRODUCTDESCRIPTIONS ...

Page 71: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 118: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 318: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 472: ...C H A P T E R 5 ADJUSTMENT ...

Page 477: ...C H A P T E R 6 MAINTENANCE ...

Page 491: ...C H A P T E R 7 AcuLaserC4100 ...

Page 548: ......

Page 549: ......

Page 550: ......

Page 551: ......

Page 552: ......

Page 553: ......

Page 554: ......

Page 555: ...C H A P T E R 8 AcuLaserC3000 ...

Page 579: ...Model AcuLaser C3000 Board C569MAIN BOARD Sheet 1 of 5 Rev B ...

Page 580: ...Model AcuLaser C3000 Board C569MAIN BOARD Sheet 2 of 5 Rev B ...

Page 581: ...Model AcuLaser C3000 Board C569MAIN BOARD Sheet 3 of 5 Rev B ...

Page 582: ...Model AcuLaser C3000 Board C569MAIN BOARD Sheet 4 of 5 Rev B ...

Page 583: ...Model AcuLaser C3000 Board C569MAIN BOARD Sheet 5 of 5 Rev B ...

Page 584: ...C H A P T E R 9 APPENDIX ...

Page 674: ......

Page 675: ......

Page 676: ......

Page 677: ......

Page 678: ......

Page 679: ......

Page 680: ......