Installation Instructions

AN2 Series

11

Align Projector Image

Using remote control included with projector:

1.

Select

MENU

2.

Select

SETTINGS

3.

Select

PATTERN

4.

Select

TEST PATTERN

5.

Use the test pattern projected on the whiteboard to roughly

align image to whiteboard, and make the necessary

projector adjustments following instructions included with

Epson projector and using the following adjustment

instructions for the mount.

IMPORTANT ! :

The projected image should NEVER

project onto the whiteboard frame. An image overlapping

onto the whiteboard frame may prevent the projector

touch sensor from working properly.

Projector Adjustments

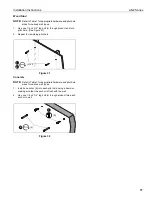

Roll Adjustment (Horizontal Tilt)

Adjust projector so that the left and right vertical lines of the test

pattern are parallel with each other and each side of

whiteboard.

1.

Loosen ROLL adjustment locking screw using a #2 Phillips

screwdriver. (See Figure 13)

2.

Turn ROLL micro-adjustment screw right or left using a #2

Phillips screwdriver until image is properly aligned on target.

3.

Tighten ROLL adjustment locking screw using a #2 Phillips

screwdriver.

Figure 13

Yaw Adjustment (Rotation)

Adjust projector so that the top and bottom horizontal lines of

the test pattern are parallel with each other and with top and

bottom of whiteboard.

1.

Loosen yaw adjustment locking screw using a #2 Phillips

screwdriver. (See Figure 14)

2.

Turn yaw micro-adjustment screw right or left using a #2

Phillips screwdriver until image is properly aligned on target.

3.

Tighten yaw adjustment locking screw using a #2 Phillips

screwdriver. (See Figure 14)

Figure 14

1

3

2

2

1

2

3

2