EPSON Stylus CX4300/CX4400/CX5500/CX5600/DX4400/DX4450

Revision A

DISASSEMBLY/ASSEMBLY

Disassembling Printer Mechanism

79

4.6.3 CR Scale

Part/Unit that should be removed before removing CR Scale

Document Cover / ASF Cover / Support Arm / Scanner Unit / Middle Case /

Panel Unit

Removal Procedure

1.

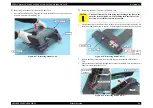

Release the right end of the CR Scale from the tab.

2.

Release the CR Scale from the slit of the CR Encoder Sensor.

Figure 4-41. Removing CR Scale (1)

3.

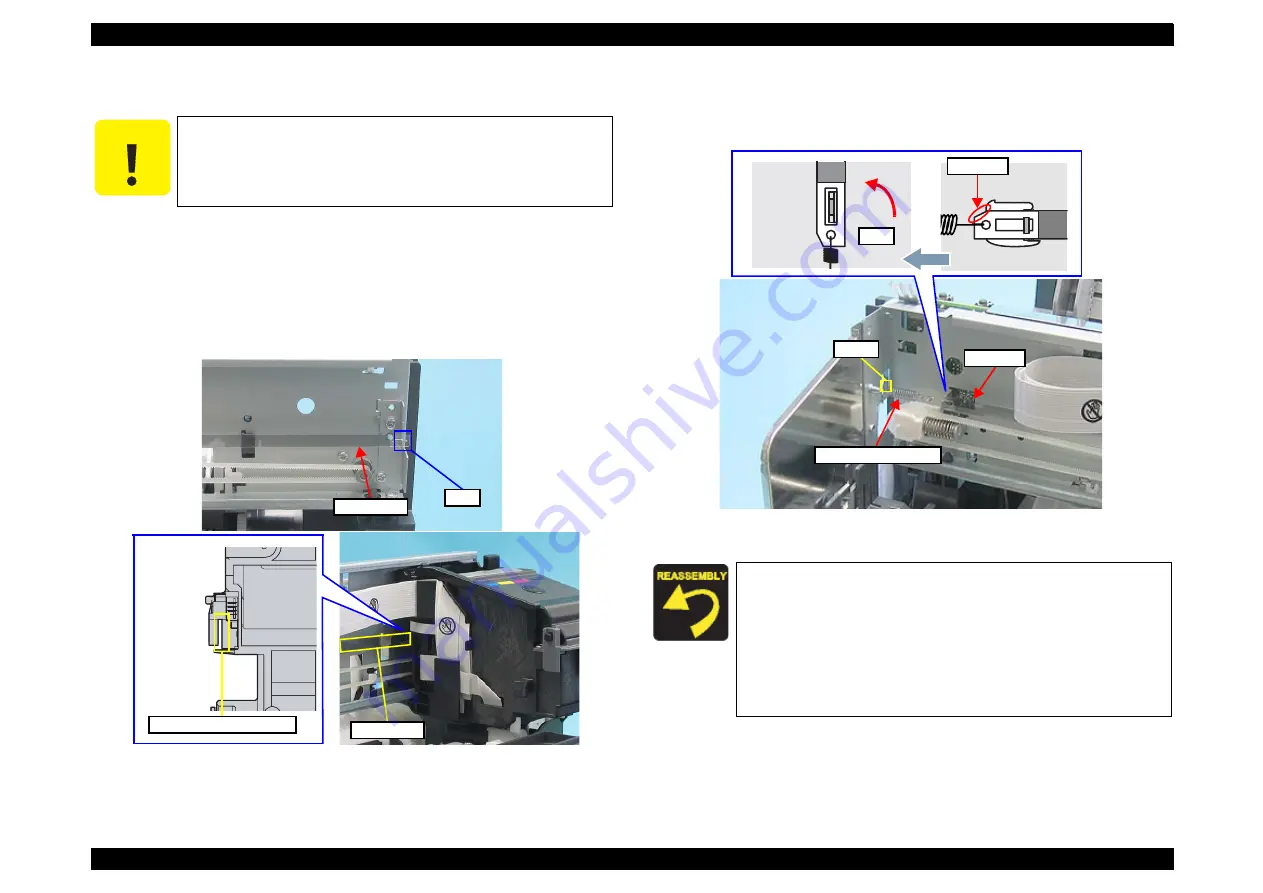

Release the Extension Spring 3.289 from the hook of the Main Frame.

4.

Rotate the CR Scale 90 degrees as shown in the figure and remove the scale

from the Main Frame.

Figure 4-42. Removing CR Scale (3)

C A U T I O N

Pay attention to the following instructions:

Do not touch the CR Scale with bare hands.

Do not damage the CR Scale.

Do not stretch Extension Spring 3.289 too much.

CR Scale

Tab

CR Scale

Slit of CR Encoder Sensor

When installing the CR Scale, pay attention to the following

instructions.

The CR Scale must be set between the sides of the CR Encoder

Sensor, but not touching either side. If the CR Scale is rubbing

against either wall (emitter or receiver), it should be re-

installed.

Chipped part of the CR Scale should be facing upward.

Extension Spring 3.289 should not be twisted.

CR Scale

Extension Spring 3.289

Hook

Chipped

90 º

Summary of Contents for CX4400 - Stylus Color Inkjet

Page 5: ...Revision Status Revision Issued Date Description A April 23 2007 First Release ...

Page 8: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 23: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 32: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 60: ...C H A P T E R 4 DISASSEMBLY ASSEMBLY ...

Page 100: ...C H A P T E R 5 ADJUSTMENT ...

Page 108: ...C H A P T E R 6 MAINTENANCE ...

Page 115: ...C H A P T E R 7 APPENDIX ...

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......