Maintenance 5. Replacing the Motors (Joint #1)

E2C Rev.6

111

(6) Install the base connector box.

For details on the installation method, refer to

Maintenance: 3.4 Base Connector

Box

.

(7) Perform the calibration of Joint #1.

For details on the calibration method, refer to

Maintenance: 14. Calibration

.

5.3.2 SM, CM Type Manipulators

Removal

(1) Remove the base connector box.

For details on the removal method, refer to

Maintenance: 3.4 Base Connector Box

.

(2) Disconnect the connectors X110 and X11.

To disconnect the X110 connector, pull it out while pushing the projection next to the

connector.

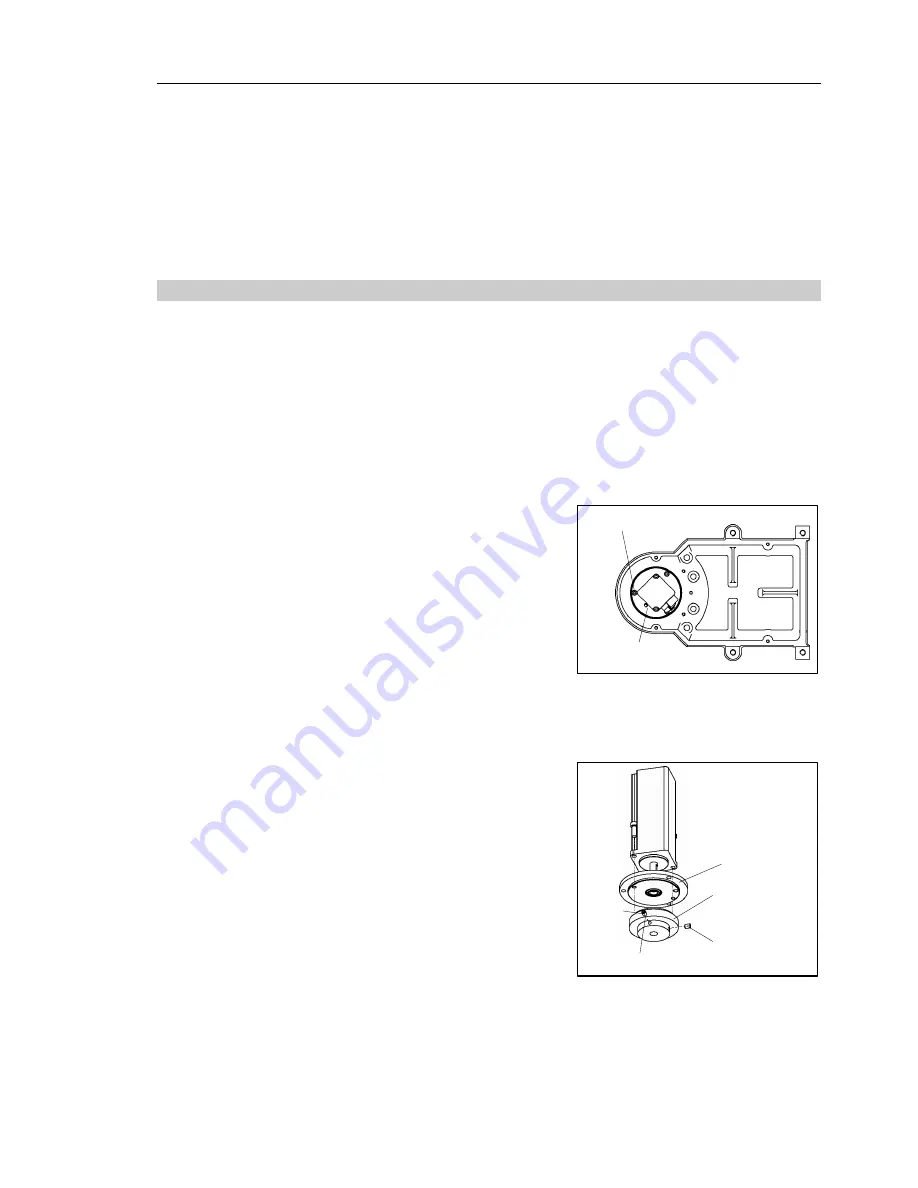

(3) Remove the Joint #1 motor unit from the

base.

To do so, unscrew the bolts from the Joint

#1 motor flange. Then, pull out the motor

straight and upward.

Be careful not to lose the oil seal coated

with black rubber.

If the motor cannot be pulled out easily,

pull it out while moving Arm #1 slowly by

hand.

Motor flange

3-M4

×

15

(4) Remove the waveform generator from the

Joint #1 motor.

There is a brass bushing in one of the

setscrew holes. Be careful not to lose it.

(5) Remove the motor flange from the Joint #1

motor.

Bushing

Waveform

generator

Motor flange

M4

×

6

M4

×

6

)

NOTE

Summary of Contents for E2C Series

Page 1: ...SCARA ROBOT E2C series MANIPULATOR MANUAL Rev 6 EM069R1409F ...

Page 2: ...MANIPULATOR MANUAL E2C series Rev 6 ...

Page 8: ...vi E2C Rev 6 ...

Page 14: ......

Page 82: ......

Page 92: ...Maintenance 2 General Maintenance 80 E2C Rev 6 ...

Page 118: ...Maintenance 4 Replacing the Cable Unit 106 E2C Rev 6 ...

Page 194: ...Maintenance 11 Replacing the Signal Relay Board 182 E2C Rev 6 ...