Maintenance 6. Replacing the Reduction Gear Units (Joint #1)

E2C Rev.6

131

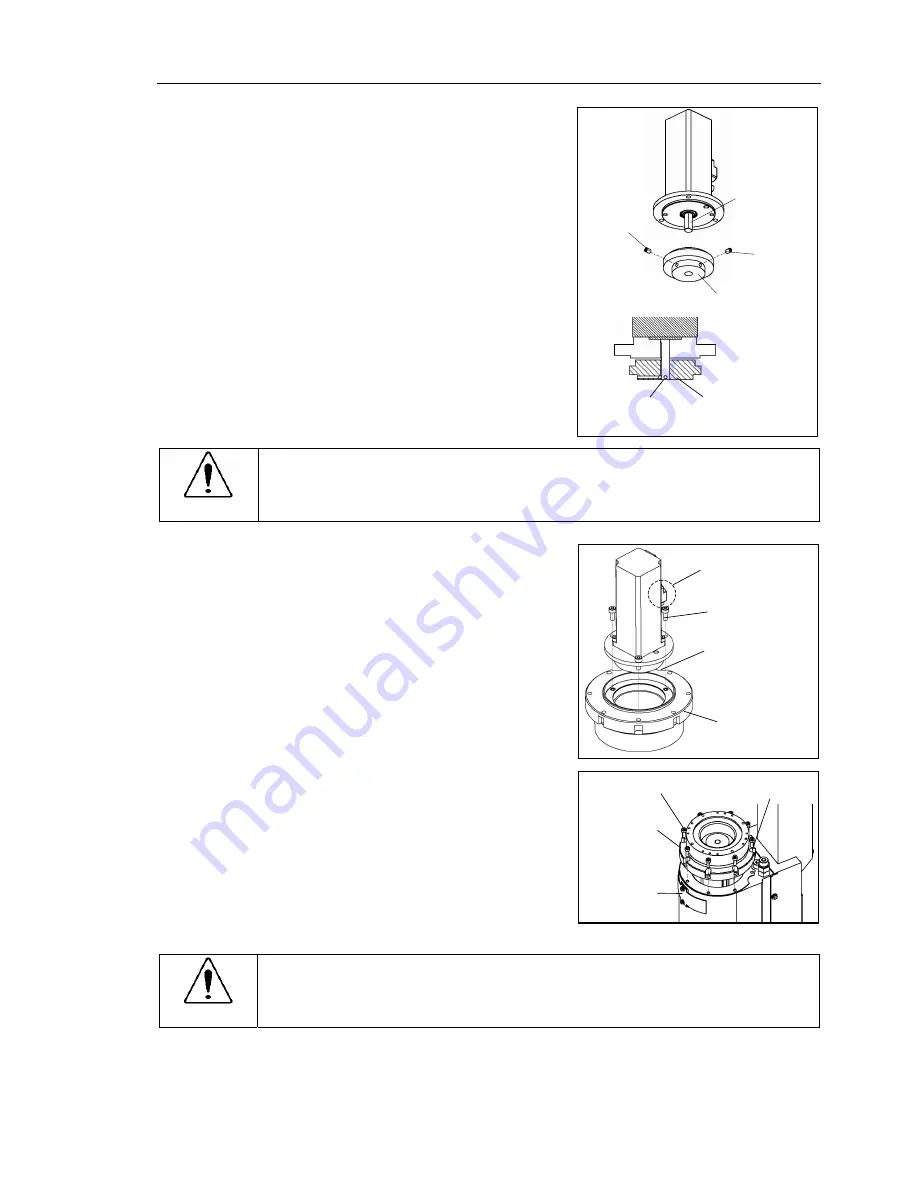

(7) Mount the waveform generator on the Joint

#1 motor.

Be sure to fit the end face of the waveform

generator to the end face of the motor

shaft. Tighten one of the setscrews on the

flat face of the motor shaft until the screw

just touches the surface. Insert a bushing

into the other setscrew hole to prevent

damage to the motor shaft. Then, tighten

both setscrews.

End face of

motor shaft

End face of waveform

generator

Bushing

M4

×

6

(Round

chamfer side)

Waveform generator

M4

×

6

(Flat side)

Flat

CAUTION

■

See the figures above for the orientation of the waveform generator. Be sure to

install the waveform generator properly. Improper installation of the waveform

generator will result in improper function of the Manipulator.

(8) Mount the Joint #1 motor unit on the Joint

#1 reduction gear unit.

Make sure that the motor cables face

toward the round-shaped cut on the

reduction gear flange as shown in the

figure on the right.

Cables

Reduction gear

flange

3-M4

×

10

Round-shaped cut

(9) Install the Joint #1 reduction gear unit on

the base.

The round-shaped cut on the reduction gear

flange must be in the position as shown in

the figure on the right.

Reduction gear

flange

Maintenance

plate

8-M4

×

12

Round-shaped cut

CAUTION

■

Never adjust (loosen or tighten) the mounting bolts between the flexspline and

cross roller bearing unit. If the mounting bolts are adjusted, the flexspline and

cross roller bearing unit must be aligned by the maker of the reduction gear unit.

Summary of Contents for E2C Series

Page 1: ...SCARA ROBOT E2C series MANIPULATOR MANUAL Rev 6 EM069R1409F ...

Page 2: ...MANIPULATOR MANUAL E2C series Rev 6 ...

Page 8: ...vi E2C Rev 6 ...

Page 14: ......

Page 82: ......

Page 92: ...Maintenance 2 General Maintenance 80 E2C Rev 6 ...

Page 118: ...Maintenance 4 Replacing the Cable Unit 106 E2C Rev 6 ...

Page 194: ...Maintenance 11 Replacing the Signal Relay Board 182 E2C Rev 6 ...