Setup & Operation 4. Setting of End Effectors

52

E2C Rev.6

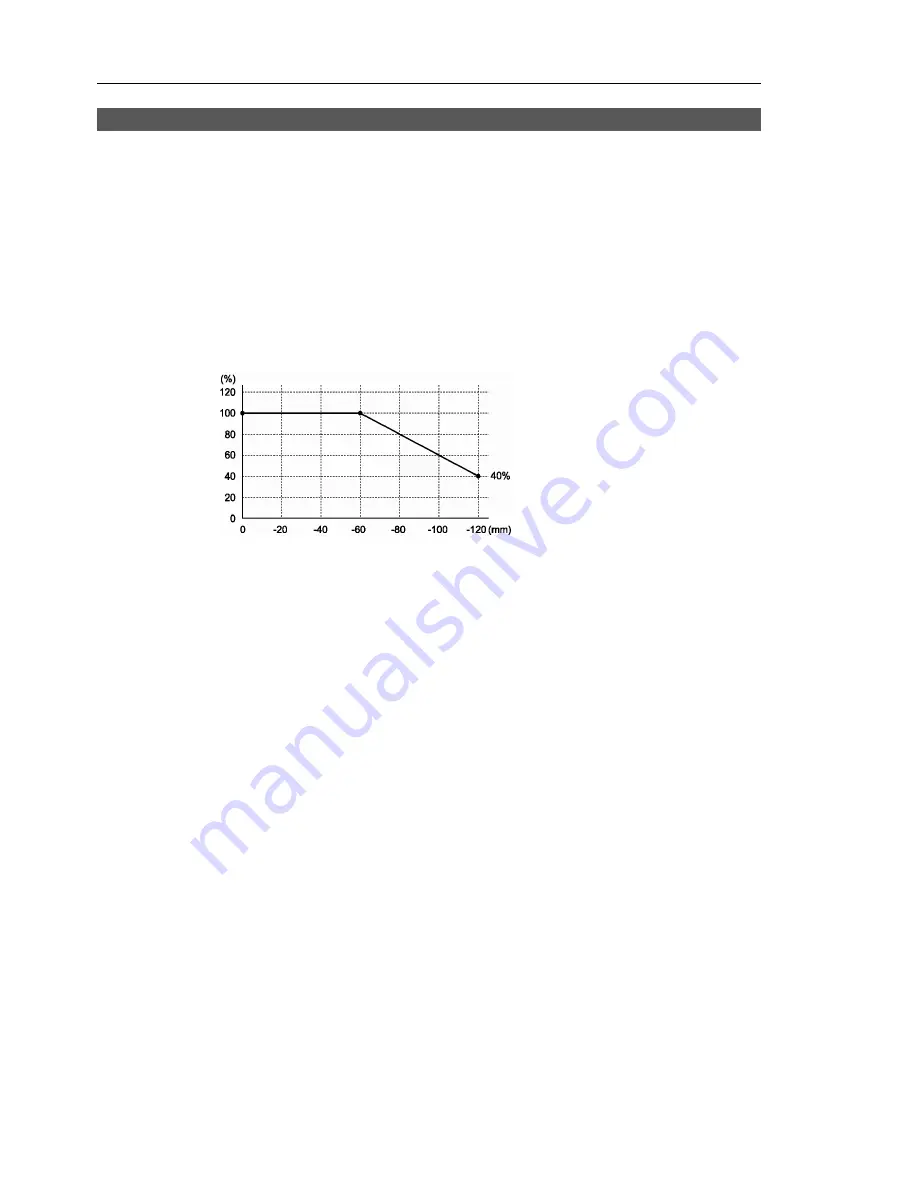

4.4 Precautions in Auto Acceleration/Deceleration of Joint #3

When you move the Manipulator horizontally with Joint #3 (Z) at a high position, the

motion time will be faster. When Joint #3 gets below a certain point (-60 mm in figure

below), then auto acceleration/deceleration is used to reduce acceleration/deceleration.

The higher the position of the shaft is, the faster the motion acceleration/deceleration is.

However, it takes more time to move Joint #3 up and down. Adjust the position of Joint

#3 for the Manipulator motion after considering the relation between the current position

and the destination position. The upper limit of Joint #3 during horizontal motion can be

set by the LIMZ command.

Automatic acceleration/deceleration vs. Joint #3 position

Height of the shaft

E2C25/35

* The percentage in the graph is based

on the acceleration/deceleration at the

upper-limited position of Joint #3

as 100%.

When moving the Manipulator horizontally while the shaft is being lowered, it may cause

over-shoot at the time of final positioning.

)

NOTE

Summary of Contents for E2C Series

Page 1: ...SCARA ROBOT E2C series MANIPULATOR MANUAL Rev 6 EM069R1409F ...

Page 2: ...MANIPULATOR MANUAL E2C series Rev 6 ...

Page 8: ...vi E2C Rev 6 ...

Page 14: ......

Page 82: ......

Page 92: ...Maintenance 2 General Maintenance 80 E2C Rev 6 ...

Page 118: ...Maintenance 4 Replacing the Cable Unit 106 E2C Rev 6 ...

Page 194: ...Maintenance 11 Replacing the Signal Relay Board 182 E2C Rev 6 ...