Setup & Operation 5. Motion Range

58

E2C Rev.6

5.2.

1

Setting the Mechanical Stops of Joints #

1

and #2

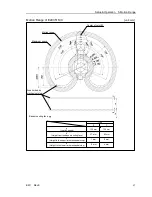

Both Joints #1 and #2 have threaded holes in the positions corresponding to the angle for

the mechanical stop settings. Tighten the bolts in holes corresponding to the angle that

you want to set.

The following figures show the positions of the threaded holes for the mechanical stop

settings of Joints #1/#2 and the setting angles (pulse value).

Joint #

1

(º: degree)

E2C25

1

*

(Table Top)

+90

°

(

1

63840 pulse) (standard)

-

90

°

(0 pulse) (standard)

+0

°

(8

1

920 pulse)

Mechanical stop of Joint #

1

(standard)

Mechanical stop for 0

°

-

0

°

(8

1

920 pulse)

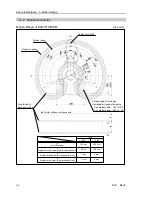

E2C35

1

*

(Table Top)

E2C35

1

*M

(Multiple Mountings)

+

11

0

°

(

1

82045 pulse) (standard)

-

11

0

°

(

-

1

8205 pulse) (standard)

+0

°

(8

1

920 pulse)

Mechanical stop of Joint #

1

(standard)

Mechanical stop for 0

°

-

0

°

(8

1

920 pulse)

+

11

0

°

(

1

82045 pulse) (standard)

-

11

0

°

(

-

1

8205 pulse) (standard)

+0

°

(8

1

920 pulse)

Mechanical stop for 0

°

-

0

°

(8

1

920 pulse)

Summary of Contents for E2C Series

Page 1: ...SCARA ROBOT E2C series MANIPULATOR MANUAL Rev 6 EM069R1409F ...

Page 2: ...MANIPULATOR MANUAL E2C series Rev 6 ...

Page 8: ...vi E2C Rev 6 ...

Page 14: ......

Page 82: ......

Page 92: ...Maintenance 2 General Maintenance 80 E2C Rev 6 ...

Page 118: ...Maintenance 4 Replacing the Cable Unit 106 E2C Rev 6 ...

Page 194: ...Maintenance 11 Replacing the Signal Relay Board 182 E2C Rev 6 ...