53

English

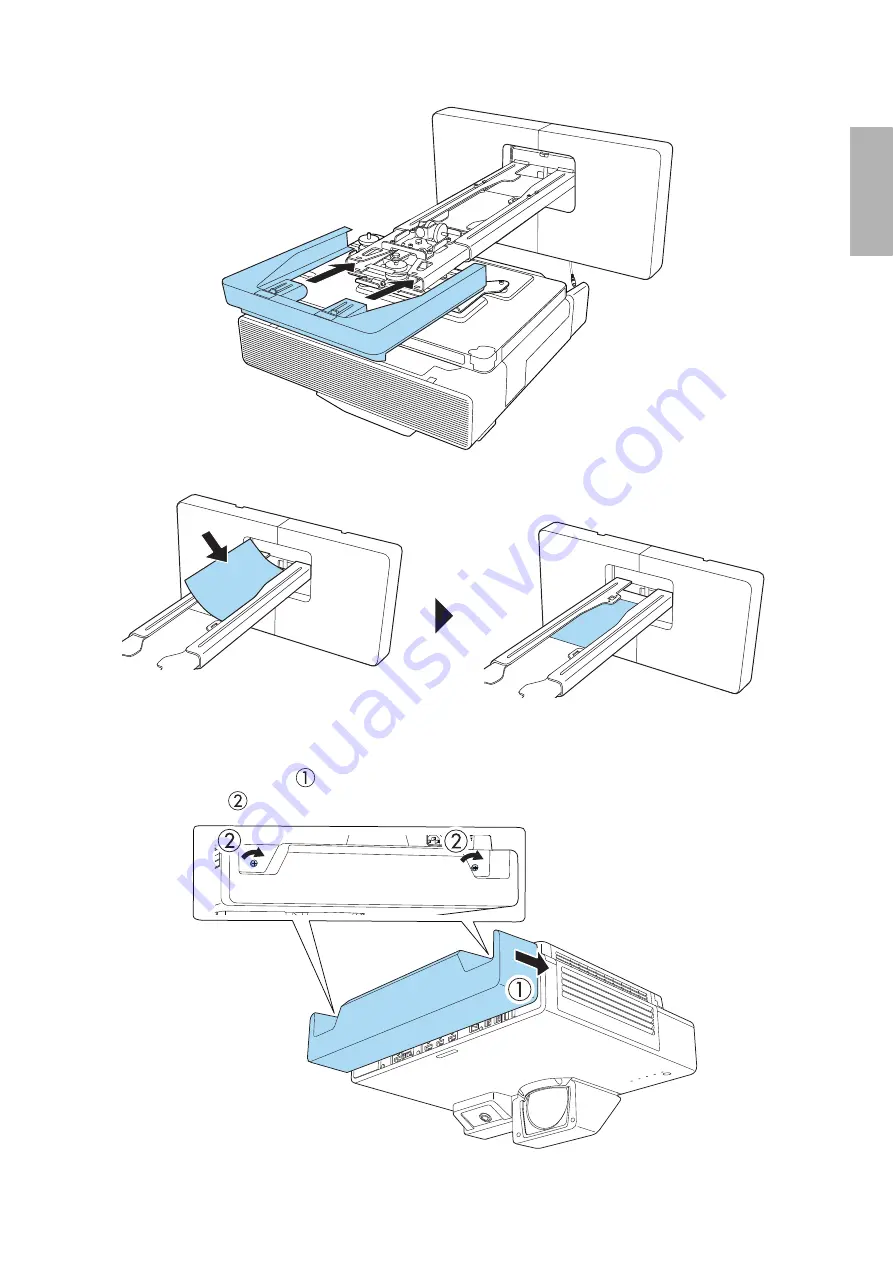

3. Attach the end cap to the mount arm.

4. If you want to cover the groove in the mount arm, attach the masking sticker as shown.

B

Attach the cable cover to the projector

Attach the cable cover (

) and use a cross-head screwdriver to tighten the screws (x2) and secure the

cable cover (

).