4. Troubleshooting (DeviceNet)

4.1.2.5 Absent Slave

Master Unit LED

MS NS

Error Description

Light

OFF

Green

Light

Blinking

Absent slave

- No slave (Error detection before

communication establishment)

- Communications power supply OFF

♦

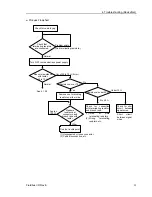

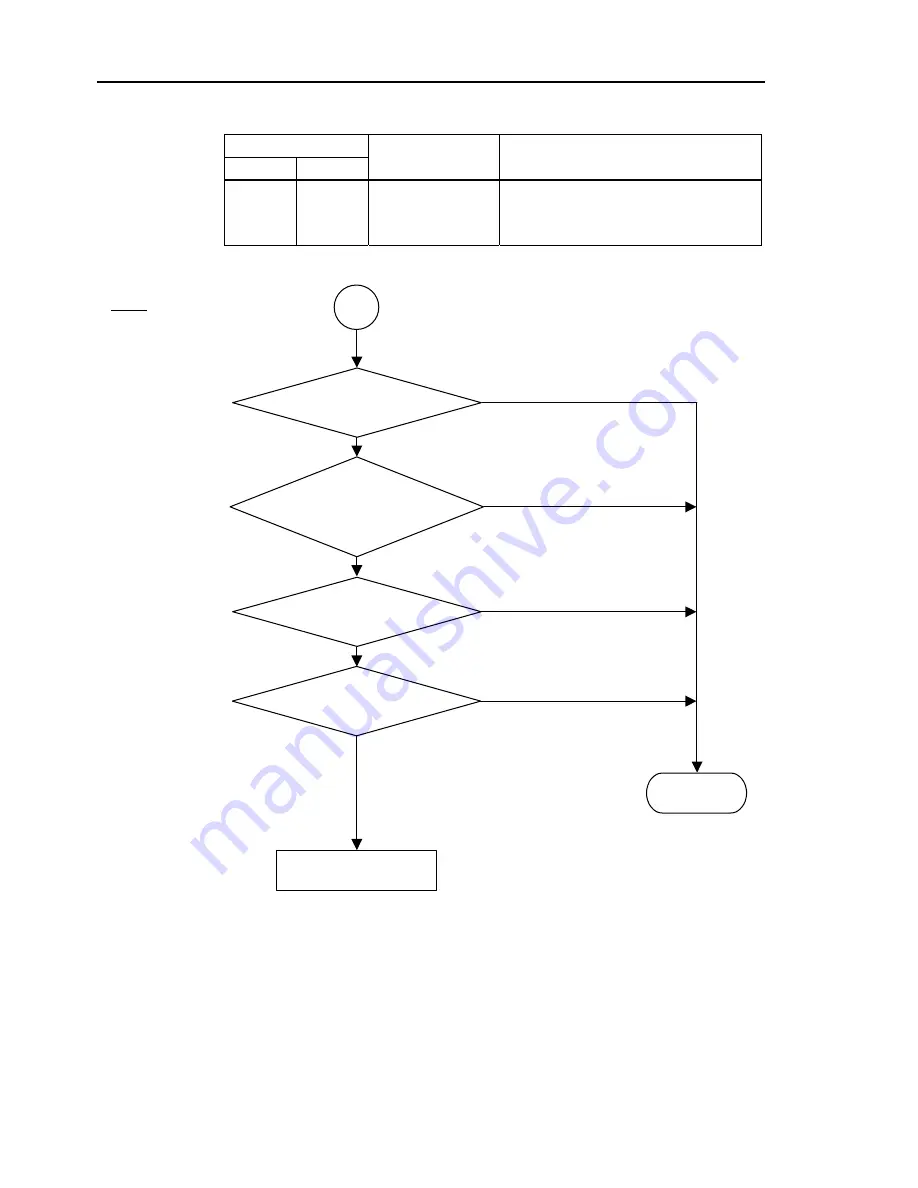

Process Flowchart

8

No Problem

Check

Check the following:

- Unconnected terminating resistor

- Unconnected or loose connector/signal wire

- Cable disconnection

Finish

No Problem

No Problem

No Problem

Problem exists. (Fix it.)

Problem exists. (Fix it.)

Problem exists. (Fix it.)

Problem exists. (Fix it.)

No problem

No problem

No problem

No problem

Measure voltage of

communications power supply

at the master unit.

Check that power is supplied to all slaves.

Check for master unit configuration.

Replace the master unit.

See 4.1.3.1 and 4.1.3.2.

94

Fieldbus I/O Rev.6

Summary of Contents for EM07ZS1647F

Page 1: ...Rev 6 EM07ZS1647F EPSON RC Option Fieldbus I O ...

Page 2: ...E PSON RC Option Fieldbus I O Rev 6 ...

Page 8: ...vi Fieldbus I O Rev 6 ...

Page 12: ...Table of Contents x Fieldbus I O Rev 6 ...

Page 80: ...2 Installation 68 Fieldbus I O Rev 6 ...

Page 88: ...3 Operation 76 Fieldbus I O Rev 6 ...

Page 164: ...5 Maintenance Parts List 152 Fieldbus I O Rev 6 ...

Page 168: ...Appendix A applicomIO Upgrade 156 Fieldbus I O Rev 6 ...