4. Troubleshooting (PROFIBUS DP)

♦

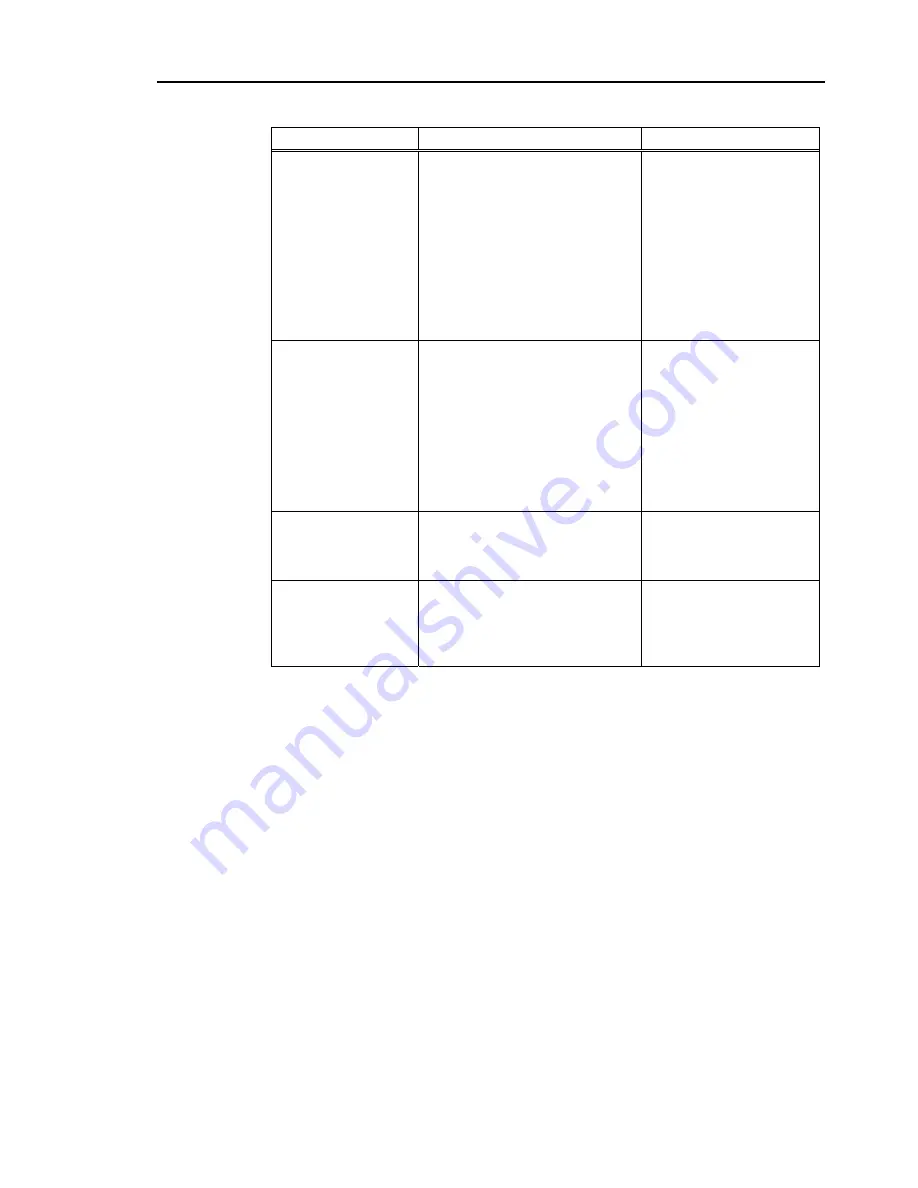

Causes of Error

Possible Cause

Examination Method

Countermeasure

{

Disconnected

terminating

resistors

{

Cable

disconnection

{

Disconnected

connector

{

Disconnected

signal wire

(1) Check that terminating

resistors are connected to both

ends of the network.

(2) Measure resistance between

signal wires with device

power supply OFF.

→

Normal: 100 to 120

Ω

z

Measuring point: Connection of

the trouble unit

z

For detail, refer to the section

4.2.3.1 Connection Problem

.

Fix the problem.

How to find the trouble

point:

Remove the terminating

resistor on one end of the

network. The trouble point

is where resistance changes

from 220

Ω

.

{

Loose connector

{

Loose signal wire

Check for the connection of

connectors and signal wires.

→

The connectors and signal

wires should be firmly

connected.

z

Checkpoint: all stations and all

branch taps

z

For details, refer to the section

4.2.3.2 Loose Connector and

Signal Wire

.

Connect the connectors and

signal wires again.

{

Broken unit

Replace the trouble unit with a

new one.

→

Verify whether the problem is

fixed.

Replace the unit with a

new one.

z

No cause is

identified.

Identify the trouble point by

dividing the network.

→

For details, refer to the section

4.2.3.4 Broken Unit

Examination

.

Fieldbus I/O Rev.6

129

Summary of Contents for EM07ZS1647F

Page 1: ...Rev 6 EM07ZS1647F EPSON RC Option Fieldbus I O ...

Page 2: ...E PSON RC Option Fieldbus I O Rev 6 ...

Page 8: ...vi Fieldbus I O Rev 6 ...

Page 12: ...Table of Contents x Fieldbus I O Rev 6 ...

Page 80: ...2 Installation 68 Fieldbus I O Rev 6 ...

Page 88: ...3 Operation 76 Fieldbus I O Rev 6 ...

Page 164: ...5 Maintenance Parts List 152 Fieldbus I O Rev 6 ...

Page 168: ...Appendix A applicomIO Upgrade 156 Fieldbus I O Rev 6 ...