Confidential

Confidential

Adjus

Adjus

t

t

m

m

e

e

nt

nt

Adjus

Adjus

t

t

m

m

e

e

nt

nt

Pr

Pr

o

o

gr

gr

a

a

m

m

60

60

Purpose

Purpose

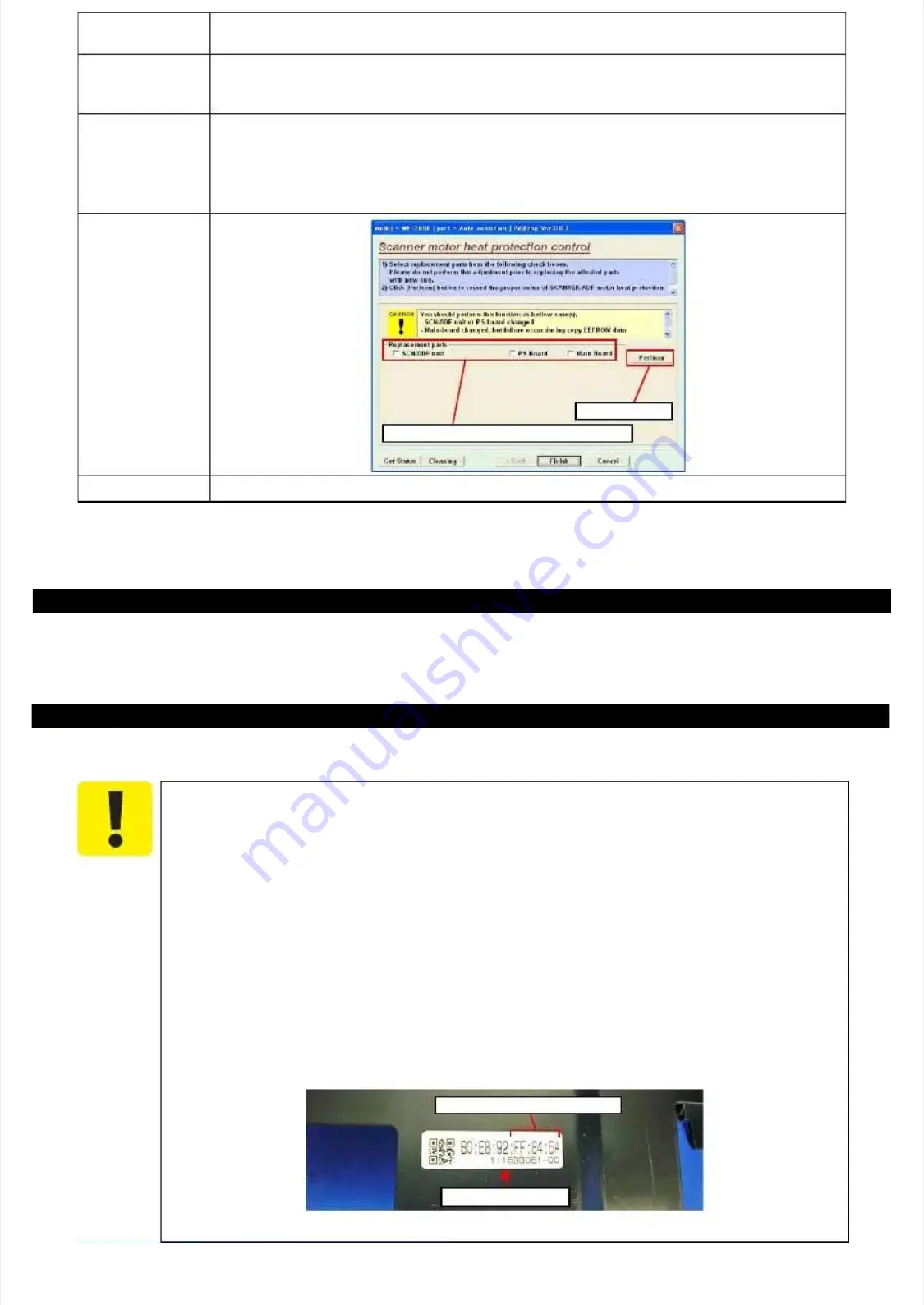

To measure the manufacturing variations of the DC motors (Scanner Motor), Main Board and Power Supply

To measure the manufacturing variations of the DC motors (Scanner Motor), Main Board and Power Supply

Board to determine the correction value used for estimating the current values of the motors.

Board to determine the correction value used for estimating the current values of the motors.

Risks if the

Risks if the

adjustment is not

adjustment is not

correctly made

correctly made

The printer cannot measure the current value of motor correctly, then the heat generation caused by motor drive cannot be

The printer cannot measure the current value of motor correctly, then the heat generation caused by motor drive cannot be

estimated accurately either, and which may results in trouble such as incorrect control of motors when allotting a cool down

estimated accurately either, and which may results in trouble such as incorrect control of motors when allotting a cool down

period a

period accordin

ccording to eac

g to each heat g

h heat generatio

eneration. In th

n. In the worst

e worst case, ex

case, excessive

cessive heat gen

heat generation

eration may caus

may cause smoke

e smoke or ign

or ignition.

ition.

Procedure

Procedure

1.

1. Select from the me

Select from the menu of the Adjus

nu of the Adjustment Progra

tment Program. Check the che

m. Check the check box of the re

ck box of the replaced par

placed parts and press the

ts and press the

“Perform” button to measure the correction value.

“Perform” button to measure the correction value.

2.

2. Turn

Turn off t

off the p

he printe

rinter an

r and tur

d turn it b

n it back o

ack on.

n.

3.

3. The correc

The correction value

tion value is automatic

is automatically measu

ally measured and

red and the measur

the measurement val

ement value is written

ue is written to the EEPROM o

to the EEPROM on

n

the Main Board.

the Main Board.

Adjustment

Adjustment

Program screen

Program screen

Remarks

Remarks

---

---

Perform button

Perform button

Check the check box of the replaced parts.

Check the check box of the replaced parts.

E

E

p

p

s

s

o

o

n

n

E

E

T

T

-

-

4

4

5

5

5

5

0

0

,

,

L

L

6

6

5

5

5

5

/

/

6

6

5

5

6

6

R

R

e

e

v

v

i

i

s

s

i

i

o

o

n

n

B

B

3.2.

3.2.2.3

2.3 MAC

MAC Addr

Address

ess Sett

Setting

ing

Setting procedure

Setting procedure

1.

1. After r

After replaci

eplacing the Main Bo

ng the Main Board Assy

ard Assy*, note do

*, note down the MAC addr

wn the MAC address wri

ess written on a labe

tten on a label on the Housi

l on the Housing Upper

ng Upper..

This setting is not necessary when the data

This setting is not necessary when the data in EEPROM on the Main Board can

in EEPROM on the Main Board can be read out.

be read out.

To avoid a conflict of MAC

To avoid a conflict of MAC address on a network, make sure to correctly follow the

address on a network, make sure to correctly follow the MAC

MAC

address setting flowchart given on the following.

address setting flowchart given on the following.

The user should be notified of

The user should be notified of the change of MAC address because of

the change of MAC address because of the following

the following

reasons.

reasons.

•• If the use

If the user has set the pr

r has set the printer

inter’s MAC ad

’s MAC address o

dress on a router, th

n a router, the repair

e repaired print

ed printer with a

er with a

new MAC address cannot be connected to the network.

new MAC address cannot be connected to the network.

•• The defa

The default prin

ult printer nam

ter name on a netw

e on a network con

ork consists

sists of “EPSO

of “EPSON” and t

N” and the last s

he last six dig

ix digits of t

its of the

he

MAC address. Therefore, the printer name becomes different from the previous one.

MAC address. Therefore, the printer name becomes different from the previous one.

You are required to enter the last six digits of the MAC address (xx:yy:zz) on the

You are required to enter the last six digits of the MAC address (xx:yy:zz) on the

adjustment program.

adjustment program.

MAC address

MAC address example: B0:E8:92:xx:yy:zz

example: B0:E8:92:xx:yy:zz

(“xx, yy, zz” represents a value unique to each printer)

(“xx, yy, zz” represents a value unique to each printer)

Figur

Figure 3-1

e 3-1.. MAC

MAC Add

Address

ress Labe

Labell

MAC Address Label

MAC Address Label

Last six digits of MAC address

Last six digits of MAC address