GENERAL DESCRIPTION

Rev. A

1-

9

1.3.2 SCSI Interface

1.3.2.1 Basic specifications

Any items not included in this specification shall be in conformance with ANSI standard X3.131-1986.

Function

The following functions are available, which are included in X3.131-1986.

1)

Bus free phase

2) Arbitration

phase

3)

Selection / Re-selection phase

4) Command

phase

Note: The LUN (Logical Unit Number) is fixed at “0” in this devise. The Command Link Function

is not supported.

5) Data

phase

Data in phase

Data out phase

6) Status

phase

7) Message

phase

Message in phase

Message out phase

8) Attention

condition

9)

Reset condition

Logic level

TTL

compatible

Electric specification

Conforms to ANSI standard X3.131-1986.

Connector

50 / 25-pin connectors

Terminator

Internal terminator

Enable to control "active" or "inactive" by a switch.

(SW = ON ... terminator available)

SCSI ID

The SCSI ID is set with a rotary switch on the rear panel.

The switch numbers are corresponded to the available address and can be set from 0 to 7, “8 - 9” is

reserved.

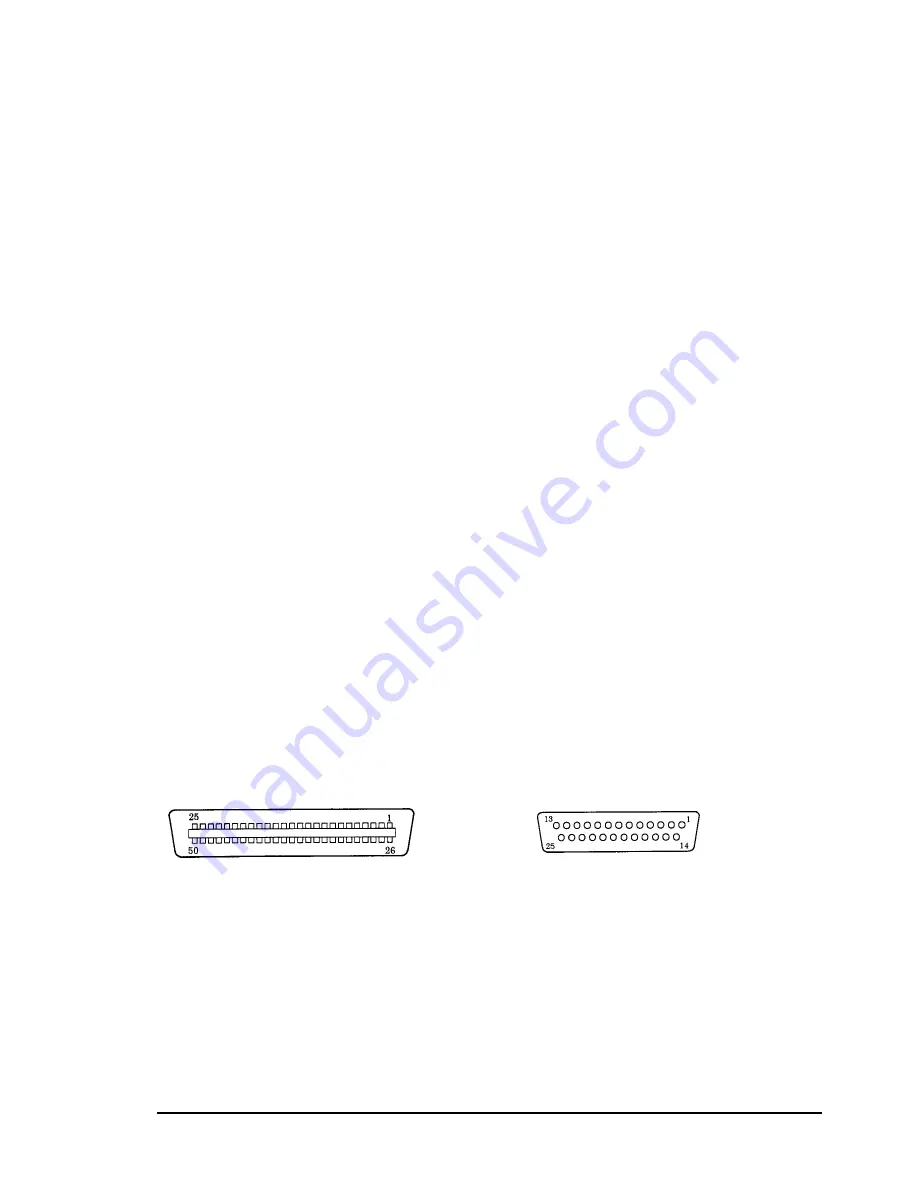

Figure 1-7. Applicable Connector

(APPHENOL 50-Pin)

Figure 1-8. Applicable Connector (D-SUB 25-Pin)

Summary of Contents for FILMSCAN 200

Page 1: ...EPSON FILM SCANNER FilmScan 200 SERVICE MANUAL SEIKO EPSON CORPORATION 4007375 ...

Page 5: ...v REVISION SHEET Revision Issued Data Contents Rev A FEBRUARY 28 1997 First issue ...

Page 8: ...EPSON SEIKO EPSON CORPORATION ...

Page 75: ...CHAPTER 4 ADJUSTMENT No adjustment is required in this product ...

Page 85: ...CHAPTER 6 MAINTENENCE 6 1 MAINTENENCE 6 1 6 2 LUBRICATION 6 1 ...

Page 86: ...APPENDIX A 1 CONNECTOR PIN ASSIGNMENTS 1 A 2 EXPLOED DIAGRAM 8 ...

Page 88: ...FilmScan 200 Rev A A 2 Figure A 2 Cable Connection SCSI Model ...

Page 95: ...APPENDIX Rev A A 9 Figure A 4 FilmScan 200 Bi D Model Exploded Diagram 2 2 ...

Page 96: ...FilmScan 200 Rev A A 10 Figure A 5 FilmScan 200 SCSI Model Exploded Diagram 1 2 ...

Page 97: ...APPENDIX Rev A A 11 Figure A 6 FilmScan 200 SCSI Model Exploded Diagram 2 2 ...

Page 98: ...FilmScan 200 Rev A A 12 Figure A 7 APS Holder option Exploded Diagram ...

Page 100: ...FilmScan 200 Rev A 6 2 Shaft 1 G 36 1 G 36 Figure 6 1 Lubrication Points ...