FX-2180 Service Manual

Disassembly and Assembly

Rev. A

4-26

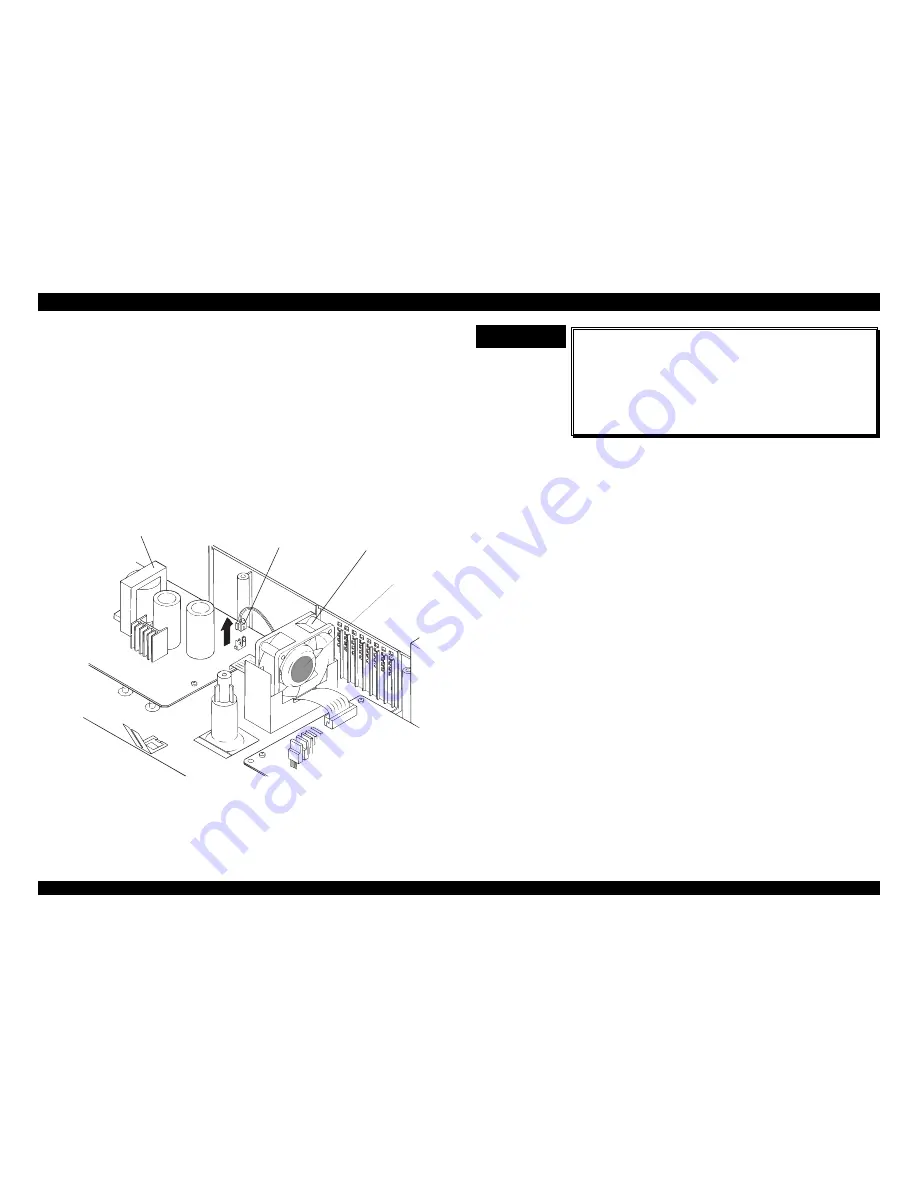

4.2.9.12 Removing the Power Supply board Assembly

1.

Remove the printer cover, the rear / front edge guide assemblies, front

cover, paper eject assembly, and rear / fronts tractor units. (Refer to

Section 4.2.1.)

2.

Remove the panel board assembly. (Refer to Section 4.2.2.)

3.

Remove the upper housing assembly. (Refer to Section 4.2.7.)

4.

Remove the five CBB screws (3

×

12) securing the power supply board

assembly.

5.

Disconnect the cable for CN3 on the main board assembly.

6.

Disconnect the cable for the fan motor from CN3 on the power supply

board assembly.

7.

Remove the power supply board assembly while pulling up the fan

motor.

F a n M o t o r

C N 3

P o w e r S u p p l y B o a r d A s s e m b l y

L a b e l s i d e

M a i n B o a r d

Figure 4-36. Removing the Power Supply Board Assembly

CHECK POINT

9

Insert the cable for CN2 on the power supply

board under the fan motor.

The tightening torque for the CBB screws (3

××

12) : 0.78

∼∼

0.98 Nm (8

∼∼

10 Kgf-cm)

Notice the direction for mounting the fan motor.

The label side of fan faces for the main board

assembly. (Refer to the above figure.)

Summary of Contents for FX-2180 - Impact Printer

Page 1: ...EPSON EPSON EPSON France S A SERVICE MANUAL FX 2180 PRODUIT ...

Page 2: ...6 59 0 18 3LQ PSDFW RW 3ULQWHU EPSON FX 2180 4009047 ...

Page 6: ...REVISION STATUS Rev Date Page s Contents A 1998 04 02 All First release ...

Page 11: ...PRODUCT DESCRIPTIONS 3 7 5 ...

Page 24: ...OPERATING PRINCIPLES 3 7 5 ...

Page 28: ...TROUBLESHOOTING 3 7 5 ...

Page 43: ...DISASSEMBLY AND ASSEMBLY 3 7 5 ...

Page 76: ...ADJUSTMENT 3 7 5 ...

Page 86: ...MAINTENANCE 3 7 5 ...

Page 89: ...APPENDIX 3 7 5 ...

Page 101: ......

Page 104: ......