Summary of Contents for FX Series

Page 56: ...EPSON PRINTERS PARTS LISTS ...

Page 58: ...EPSON PRINTERS PARTS LISTS 18 3 5 ...

Page 60: ...EPSON PRINTERS PARTS LISTS a 3 7 ...

Page 62: ...EPSON PRINTERS PARTS LISTS 19 18 Al n 3 9 ...

Page 64: ...EPSON PRINTERS PARTS LISTS f 3 11 ...

Page 66: ...EPSON PRINTERS PARTS LISTS 3 13 ...

Page 68: ...EPSON PRINTERS PARTS LISTS ...

Page 70: ...EPSON PRINTERS PARTS LISTS m 3 17 ...

Page 72: ...i ...

Page 74: ...EPSON PRINTERS PARTS LISTS m ...

Page 76: ...EPSON PRINTERS PARTS LISTS Pm 3 23 ...

Page 78: ...EPSON PRINTERS PARTS LISTS J 1 3 25 ...

Page 80: ...EPSON PRINTERS PARTS LISTS 3 27 ...

Page 82: ...EPSON PRINTERS PARTS LISTS J 3 29 ...

Page 84: ...EPSON PRINTERS PARTS LISTS 33 J 00 ...

Page 86: ...EPSON PRINTERS PARTS LISTS 10 12 3 33 1 ...

Page 88: ...EPSON PRINTERS PARTS LISTS 3 35 ...

Page 90: ...EPSON PRINTERS PARTS LISTS J 3 37 ...

Page 92: ...EPSON PRINTERS PARTS LISTS 17 15 P 3 39 ...

Page 94: ...EPSON PRINTERS PARTS LISTS J V 10 12 3 41 K ttSsfi ...

Page 99: ...PARTS LISTS EPSON PRINTERS NOTES 3 46 ...

Page 111: ...REPAIRS ADJUSTMENTS EPSON PRINTERS NOTES 4 12 ...

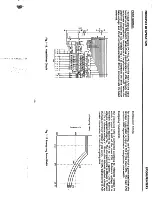

Page 114: ...EPSON PRINTERS y 31 FIGURE 5 1 5 3 FINAL ACTIONS ...

Page 115: ...FINAL ACTIONS EPSON PRINTERS 17 FIGURE 5 2 5 4 ...

Page 116: ...EPSON PRINTERS V A FIGURE 5 3 5 5 FINAL ACTIONS ft 9 ...

Page 118: ...EPSON PRINTERS 12 1 J t32 M iv FIGURE 5 4 5 7 FINAL ACTIONS A a ...

Page 119: ...FINAL ACTIONS FIGURE 5 5 5 8 EPSON PRINTERS 38 ...

Page 120: ......

Page 149: ...rr Si rrV i t jr f 1 t ...