Maintenance 8. Arm #4

170

G10 / G20 Rev.20

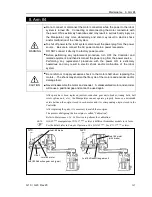

Joint #4 motor

Installation: G10

(1) Mount the U1 pulley and the motor plate to the

new Joint #4 motor.

Pull the pulley to the motor side with 50N force to

pressurize the bearing while securing the pulley.

Tighten one of the set screws on the flat face of

the motor shaft until the screw just touches the

surface.

Insert a bushing into the other set screw hole to

prevent damage to the motor shaft. Then, tighten

both set screws.

2-M4

×

8

set screw

M4 bushing

Motor plate

Joint #4 motor

Pulley

Bearing

2-M4

×

15

(2) Place the Joint #4 motor unit in the arm so that the

motor cable faces toward the left from the end of

Arm #2.

4-M4

×

15

+

Washer

Joint #4

motor unit

(3) Place the U belt around the U1 pulley and the U2

pulley so that the gear grooves of the belt are fit

into those of the pulleys completely.

(4) Loosely secure the Joint #4 motor unit to Arm #2.

Loosely secure the Joint #4 motor unit to Arm #2

so that the motor unit can be moved by hand, and

it will not tilt when pulled. If the unit is secured

too loose or too tight, the belt will not have the

proper tension.

U belt

U2 pulley U1 pulley

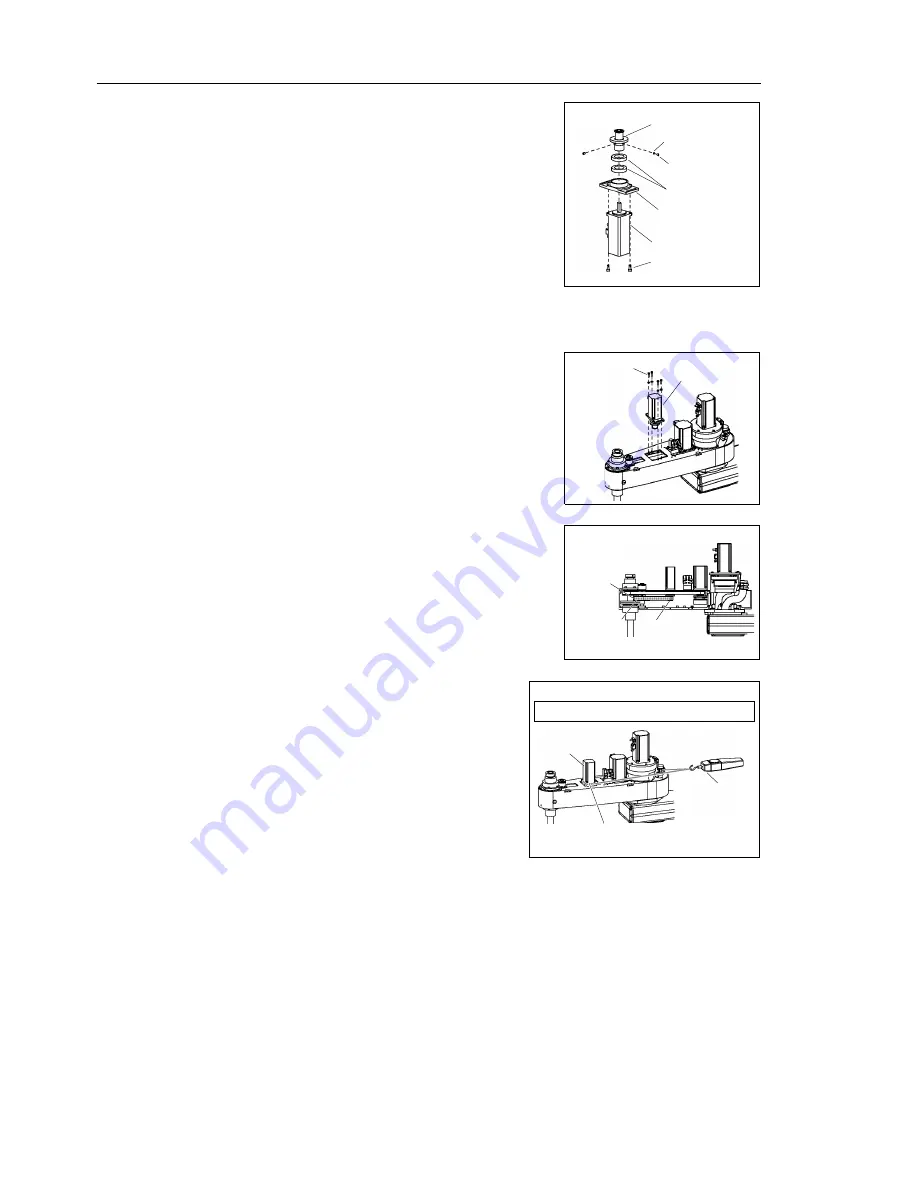

(5) Apply the proper tension to the U belt, and

then secure the Joint #4 motor unit.

To do so, pass a suitable cord or string

around the Joint #4 motor unit near its

mounting plate. Then, pull the cord using a

force gauge or similar tool to apply the

specified tension shown in the figure on the

right.

Make sure that the brake cables do not touch

the pulley.

4-M4

×

15

+

Washer

G10 : U belt tension = 160 N (16.3 kgf)

Force gauge

Joint #4

motor unit

NOTE

Summary of Contents for G10 Series

Page 1: ...Rev 20 EM183R3619F SCARA ROBOT G10 G20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL G10 G20 series Rev 20 ...

Page 8: ...vi G10 G20 Rev 20 ...

Page 14: ......

Page 102: ...Setup Operation 5 Motion Range 90 G10 G20 Rev 20 ...

Page 104: ......