Maintenance 8. Arm #4

182

G10 / G20 Rev.20

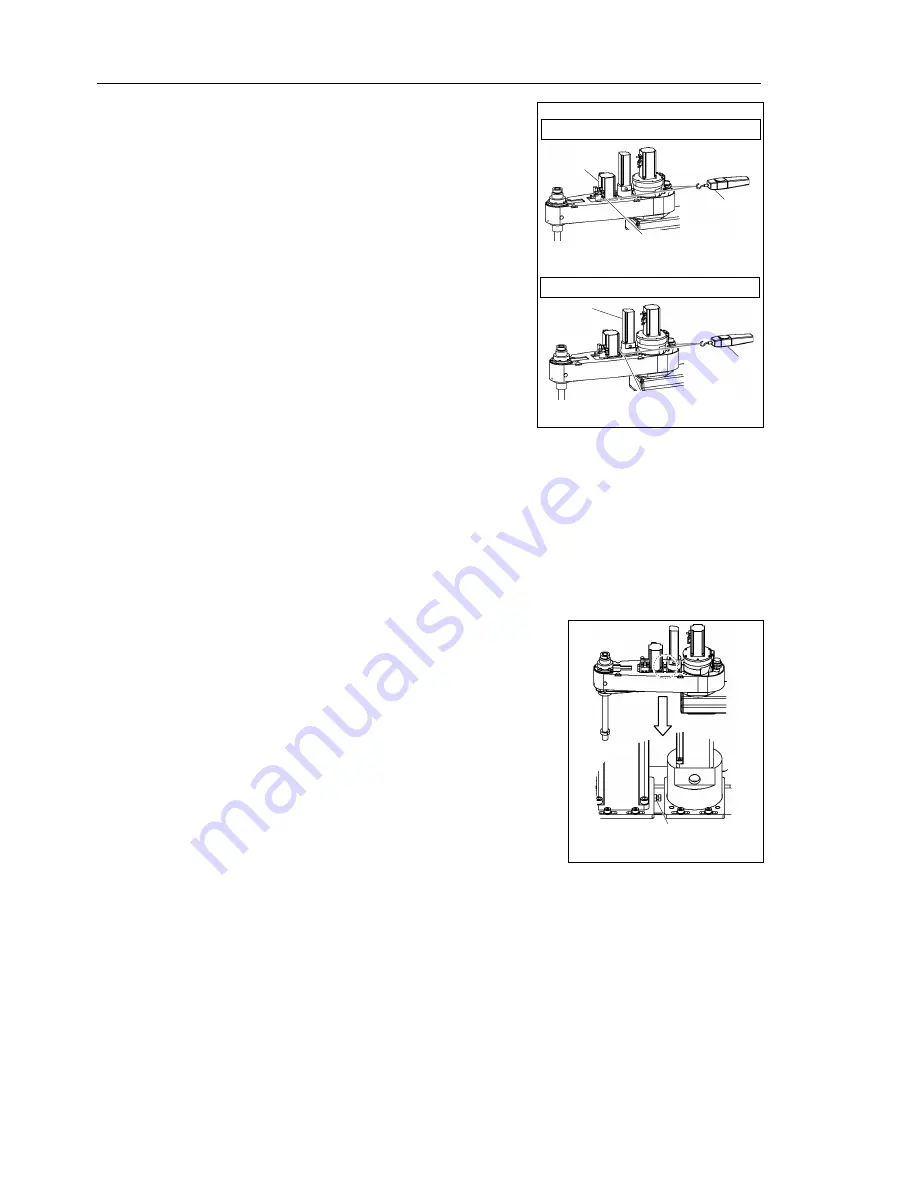

(7) Apply the proper tension to the Z belt and U

belt, and then secure the Joint #3 motor unit

and Joint #4 motor unit.

To do so, pass a suitable cord or string around

each motor unit near its mounting plate.

Then, pull the cord using a force gauge or

similar tool to apply the specified tension

shown in the figure on the right.

Make sure that the brake cables do not touch

the pulley.

4-M4

×

15

+

Washer

G20 : Z belt tension = 130 N (13.3 kgf)

Force gauge

Joint #3

motor unit

4-M4

×

15

+

Washer

G20 : U belt tension = 200 N (20.4 kgf)

Force gauge

Joint #4

motor unit

How to apply the proper tension to the U belt of G20

There is a bolt on the Z axis plate part to apply tension to the U belt.

(Since it is difficult to apply 200N tension on the U belt only by human power.)

The procedure to apply tension using the bolt is as follows.

We recommend the Tensometer U series from Gates Unitta for measuring the belt

tension.

Tensometer setting

Weight 5.25 g/m Width 20 mm Span 297.5 mm

1.

Loosen the nut.

Be careful about the motor flange.

It may break with too much power.

2.

Screw the bolt and push in the U axis plate.

3.

Use the ultrasonic gauge to apply the proper

tension to the U axis belt.

4.

Secure the U axis unit.

5.

Place back the bolt to the position.

Secure the nut.

6.

Loosen the nut.

G20: U belt tension

Bolt + nut for adjustment (M4)

Summary of Contents for G10 Series

Page 1: ...Rev 20 EM183R3619F SCARA ROBOT G10 G20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL G10 G20 series Rev 20 ...

Page 8: ...vi G10 G20 Rev 20 ...

Page 14: ......

Page 102: ...Setup Operation 5 Motion Range 90 G10 G20 Rev 20 ...

Page 104: ......