Maintenance 6. Arm #2

G3 Rev.14

119

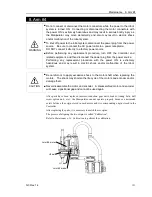

(5) Mount the circular spline to Arm #2.

Loosely secure all bolts in a crisscross

pattern so that the bolts will be secured

evenly. Then, using a torque wrench,

tighten each bolt securely in a crisscross

pattern at the torque specified in the

table below.

10-M3

×

20

8-M3

×

35

4-M3

×

20

O-ring

Arm #2

Reduction

gear unit

Arm #1

Item

Bolt type

Number of bolts

Tightening torque

Joint #2 reduction gear unit

M3

×

20

10

3.0 N

⋅

m (30.6 kgf

⋅

cm)

Be careful not to apply too much force since it may damage the parts

(6) Apply grease (SK-2) inside the flexspline.

Grease volume 8 g

(7) Install the O ring to the Arm #1.

(8) Install and secure the flexspline.

Slide the Arm #2 to the right/left to adjust the holes position.

(9) Execute installation steps (2) to (12) in

Maintenance: 6.1 Replacing Joint #2 Motor

.

NOTE

Summary of Contents for G3 Series

Page 1: ...Rev 14 EM183R3623F SCARA ROBOT G3 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL G3 series Rev 14 ...

Page 8: ...vi G3 Rev 14 ...

Page 14: ......

Page 84: ...Setup Operation 5 Motion Range 72 G3 Rev 14 ...

Page 86: ...74 ...

Page 200: ...Maintenance 15 Maintenance Parts List 188 G3 Rev 14 ...