Setup & Operation 5. Motion Range

74

G6 Rev.21

(1) Turn OFF the Controller.

(2) Install a hexagon socket head cap bolt into the hole corresponding to the setting angle,

and tighten it.

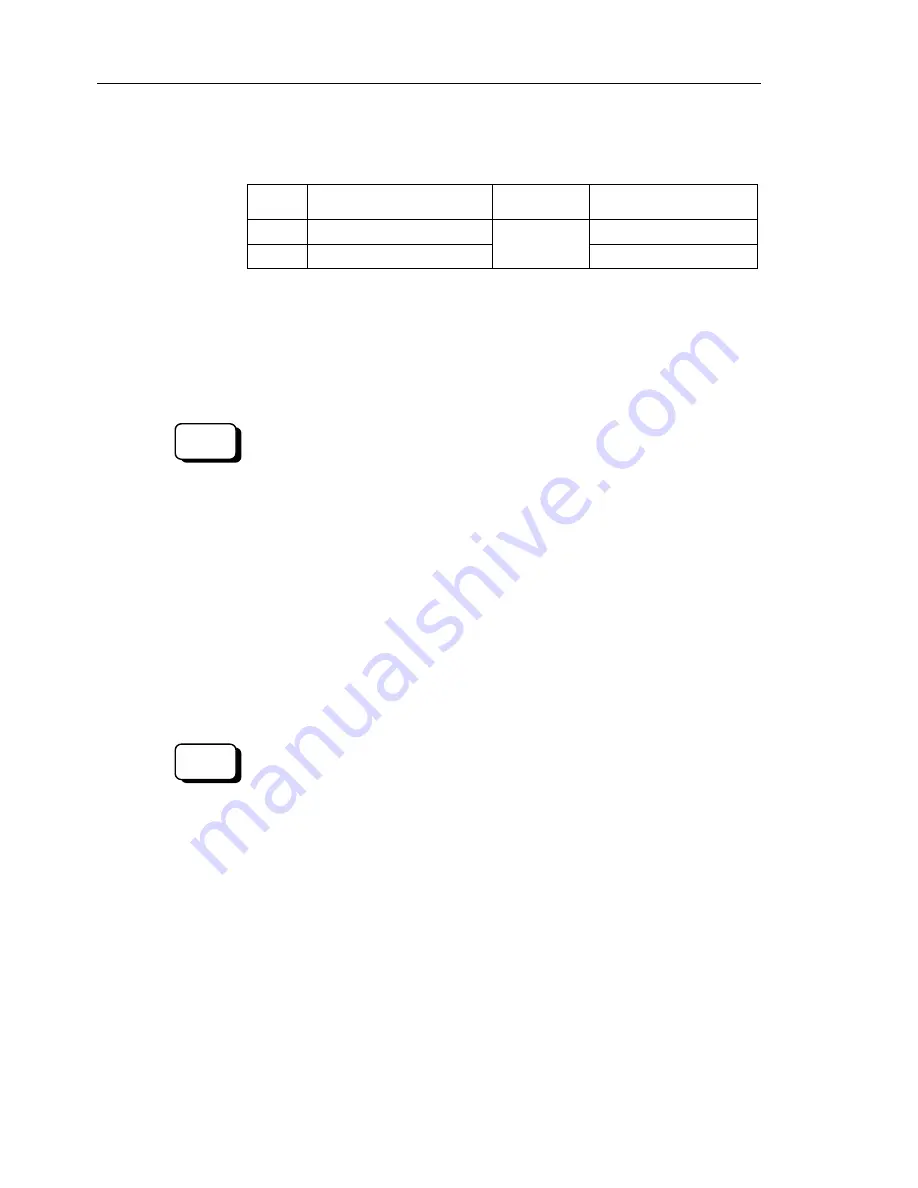

Joint Hexagon socket head cap

bolt (fully threaded)

The number

of bolts

Recommended

tightening torque

1

M10 × 20

1 bolt /

one side

127.4 N

⋅

m (1300 kgf

⋅

cm)

2

M8 × 10

37.2 N

⋅

m (380 kgf

⋅

cm)

(3) Turn ON the Controller.

(4) Set the pulse range corresponding to the new positions of the mechanical stops.

Be sure to set the pulse range inside the positions of the mechanical stop range.

Example: Using G6-**1S*

The angle of Joint #1 is set from

–

135 degrees to +135 degrees.

The angle of Joint #2 is set from

-

125 degrees to +125 degrees.

EPSON

RC+

Execute the following commands from the [Command Window].

>JRANGE 1,-1310720,6553600

' Sets the pulse range of Joint #1

>JRANGE 2,-22275556

' Sets the pulse range of Joint #2

>RANGE

' Checks the setting using Range

-1310720,6553600,-2275556,2275556,-1976708

,0,-1961226, 1961226

(5) Move the arm by hand until it touches the mechanical stops, and make sure that the

arm does not hit any peripheral equipment during operation.

(6) Operate the joint changed at low speeds until it reaches the positions of the minimum

and maximum pulse range. Make sure that the arm does not hit the mechanical

stops. (Check the position of the mechanical stop and the motion range you set.)

Example: Using G6-**1S*

The angle of Joint #1 is set from

-

85 degrees to +115 degrees.

The angle of Joint #2 is set from

-

132 degrees to +132 degrees.

EPSON

RC+

Execute the following commands from the [Command Window].

>MOTOR ON

' Turns ON the motor

>CP ON

' Enters low-power mode

>SPEED 5

' Sets at low speeds

>PULSE -1310720,0,0,0

' Moves to the min. pulse position of Joint #1

>PULSE 6553600,0,0,0

' Moves to the max. pulse position of Joint #1

>PULSE 2621440,-2275556,0,0

' Moves to the min. pulse position of Joint #2

>PULSE 2621440,2275556,0,0

' Moves to the max. pulse position of Joint #2

The Pulse command (Go Pulse command) moves all joints to the specified positions

at the same time. Specify safe positions after considering motion of not only the

joints whose pulse range have been changed, but also other joints.

In this example, Joint #1 is moved to the center of its motion range (pulse value:

2621440) when checking Joint #2.

If the arm is hitting the mechanical stops or if an error occurs after the arm hits the

mechanical stops, either reset the pulse range to a narrower setting or extend the

positions of the mechanical stops within the limit.

NOTE

Summary of Contents for G6 series

Page 1: ...Rev 21 EM183R3621F SCARA ROBOT G6 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL G6 series Rev 21 ...

Page 8: ...vi G6 Rev 21 ...

Page 14: ......

Page 94: ......

Page 216: ...Maintenance 14 Maintenance Parts List 204 G6 Rev 21 ...