Testing the Printer

Now that your printer is fully assembled, you can use its built-in self

test function to see that the printer is working correctly before you

connect it to a computer. You should perform this test to make sure that

your printer was not damaged during shipping and that the ribbon is

correctly installed.

Before running the self test, you need to connect the printer to an

electrical outlet and load a sheet of paper.

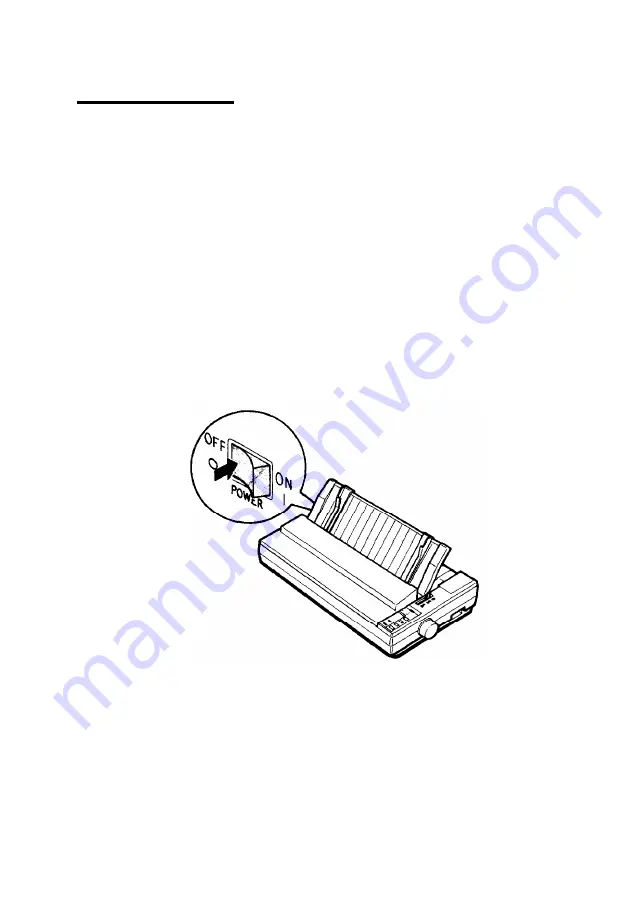

Plugging in the Printer

1.

Make sure that the printer is turned off.

1-14

Setting Up the Printer

Summary of Contents for LQ-1010

Page 1: ......

Page 2: ......

Page 148: ...The Cut Sheet Feeder 2 Remove the printer cover 5 18 Using the Printer Options ...

Page 284: ...Appendix Proportional Width Table A 2 Character Tables A 6 A 1 ...

Page 304: ......

Page 308: ......