Product Description

Service Manual

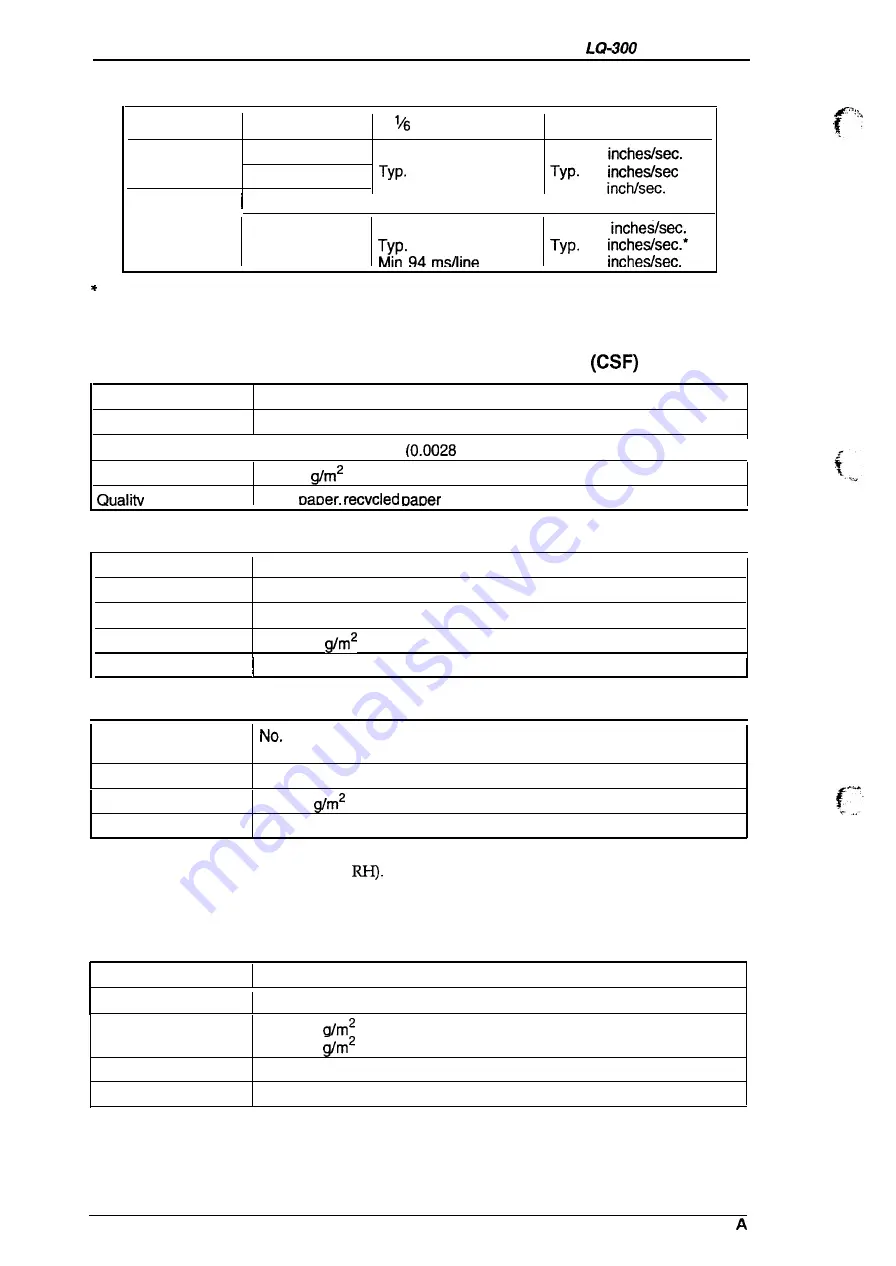

Table 1-3. Feeding

Speed

Lever Position

Feeding

inch Line Feed

Continuous Feed

Friction

Max. 94 ins/line

Max 3.6

o, 1

Tractor

80 ins/line (*)

3.3

(*)

Min. 75 ins/line

Min. 2.8

Friction

I

I

2-5

Max. 106

redline

Max. 2.8

Tractor

104 ins/line (*)

2.5

Min. 2.2

Feed speed is varies depending on the motor driving voltage.

1.2.1.2 Paper Specifications

Table

1-4. Specifications for Cut Sheet Paper

Width

182 mm -216 mm (7.2 in. -8.5 in.)

Length

210 mm -364 mm (8.3 in. -14.3 in.)

Thickness

10.07

mm -0.12 mm

in. -0.0047 in.)

I

Weight

64-90

(18 -24 lb.)

Plain

Table 1-5. Specifications for Cut Sheet Paper (Manual Insertion)

Width

148 mm -257 mm (5.8 in. -10.1 in.)

Length

182 mm -364 mm (7.2 in. -14.3 in.)

Thickness

0.065 mm -0.14 mm (0.0025 in. -0.0055 in.)

Weight

52.3-90

(14 -24 lb.)

Quality

Plain paper, recycled paper

Table 1-6. Specifications for Envelopes

Size

6

Width x Length: 166 mm x 92 mm (6.5 in. x 3.6 in.)

No. 10

Width x Length: 240 mm x 104 mm (9.5 in. x 4.1 in.)

Thickness

0.16 mm - 0.52 mm (0.0063 in. - 0.0197 in.)

Weight

45- 91

(12 -24 lb.)

Quality

Bond paper (not curled, folded, or crumpled), plain paper, airmail paper

Notes: .

Printing of envelopes is guaranteed only at room temperature and normal humidity (15

- 25° C (59 - 77° F) ,20- 60%

●

Variations in envelope thickness must be less than 0.25 mm (0.0098 in.).

. When inserting envelopes, keep the longer side horizontal.

Table 1-7. Specifications for Continuous Paper (Single Sheet and Multi-Part)

Width

101.6 mm -

254

mm

(4.0

in. - 10.0 in.)

Total thickness

0.065 mm - 0.32 mm

(0.0025

in. - 0.012 in.)

Weights

52.3- 82

(14 - 22 lb.) — not multi-part

40- 58.2

(12 - 15 lb.) — multi-part

Copies

4 sheets (1 or 3 copies)

Quality

Plain paper, recycled paper, carbonless multi-part paper

1-4

Rev.

Summary of Contents for LQ-300 - Impact Printer

Page 1: ...EPSON TERMINAL PRINTER LQ 300 SERVICE MANUAL EPSON ...

Page 5: ...REVISION SHEET Revision Issue Date Revision Page Rev A September 28 1994 1st issue f v 1 ...

Page 34: ...c f ...

Page 101: ...Maintenance LQ 300 Service Manual Figure 6 1 LQ 300 Lubrication Points 6 2 Rev A ...

Page 110: ... Figure A 6 C130 PSB PSE Component Layout ...

Page 112: ...Appendix LC MMS vbeMantd Q ix iyii t v Figure A 8 LQ 300 Exploded Diagram 2 A 12 Rev A ...

Page 119: ... f ...