Setup & Operation 3. Environments and Installation

LS20 Rev.4

35

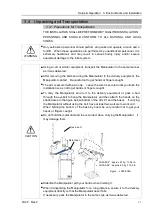

3.5 Installation Procedure

CAUTION

■

The Manipulator must be installed to avoid interference with buildings, structures,

utilities, other machines and equipment that may create a trapping hazard or

pinch points.

■

Oscillation (resonance) may occur during operation depending on rigidity of the

installation table.

If the oscillation occurs, improve rigidity of the table or change the speed or

acceleration and deceleration settings.

3.5.1 Standard-Model

CAUTION

■

Install the Manipulator with two or more people.

The Manipulator weights are as follows. Be careful not to get hands, fingers, or

feet caught and/or have equipment damaged by a fall of the Manipulator.

LS20-804* : approx. 47 kg :103.6 lb.

LS20-A04* : approx. 50 kg :110.2 lb.

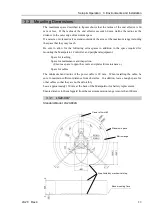

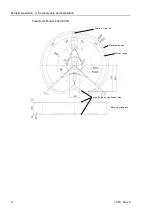

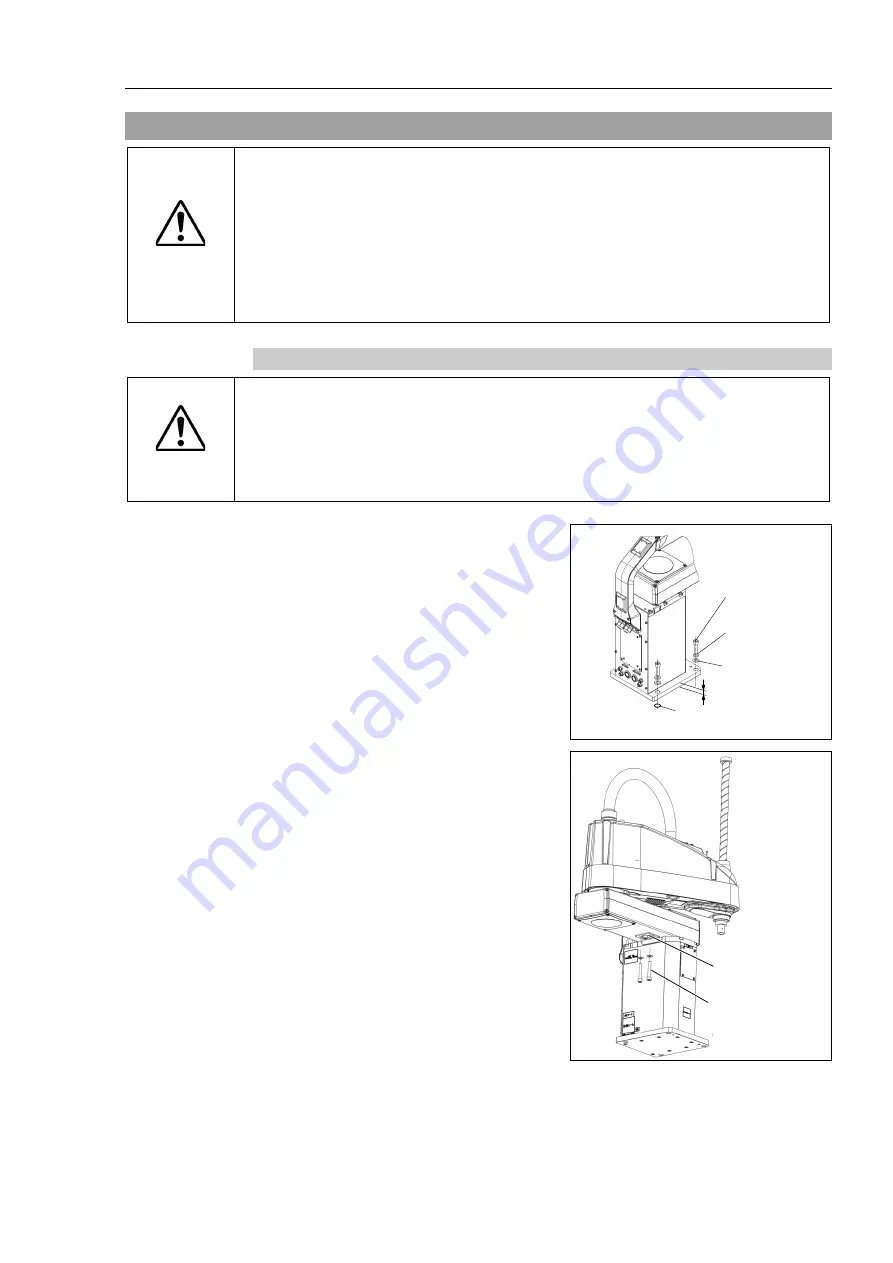

(1) Secure the base to the base table with four

bolts.

Use bolts with specifications conforming

to ISO898-1 Property Class: 10.9 or 12.9.

Tightening torque: 73.5

N∙m

(750 kgf∙cm)

18.5 mm

Screw Hole

(depth 20 mm or more)

4-M12

×

40

Spring Washer

Plane Washer

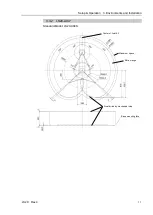

(2) Using nippers, cut off the wire tie binding

the shaft and arm retaining bracket on the

base.

2-M10

×

60

Arm lock

(3) Remove the arm lock.

NOTE

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...