Setup & Operation 5. Motion Range

54

LS20 Rev.4

5.2.1 Setting the Mechanical Stops of Joints #1 and #2

Both Joints #1 and #2 have threaded holes in the positions corresponding to the angle for

the mechanical stop settings. Install the bolts in the holes corresponding to the angle that

you want to set.

Install the bolts for the mechanical stop to the following position.

a

b

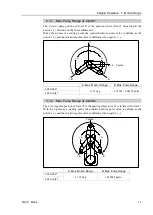

Views from the bottom of Arm #1

Joint #1 Mechanical Stops

a

b

LS20-804*

LS20-A04*

Setting Angle

122 deg

-

122 deg

Pulse Value

444188 pulse

-

444188 pulse

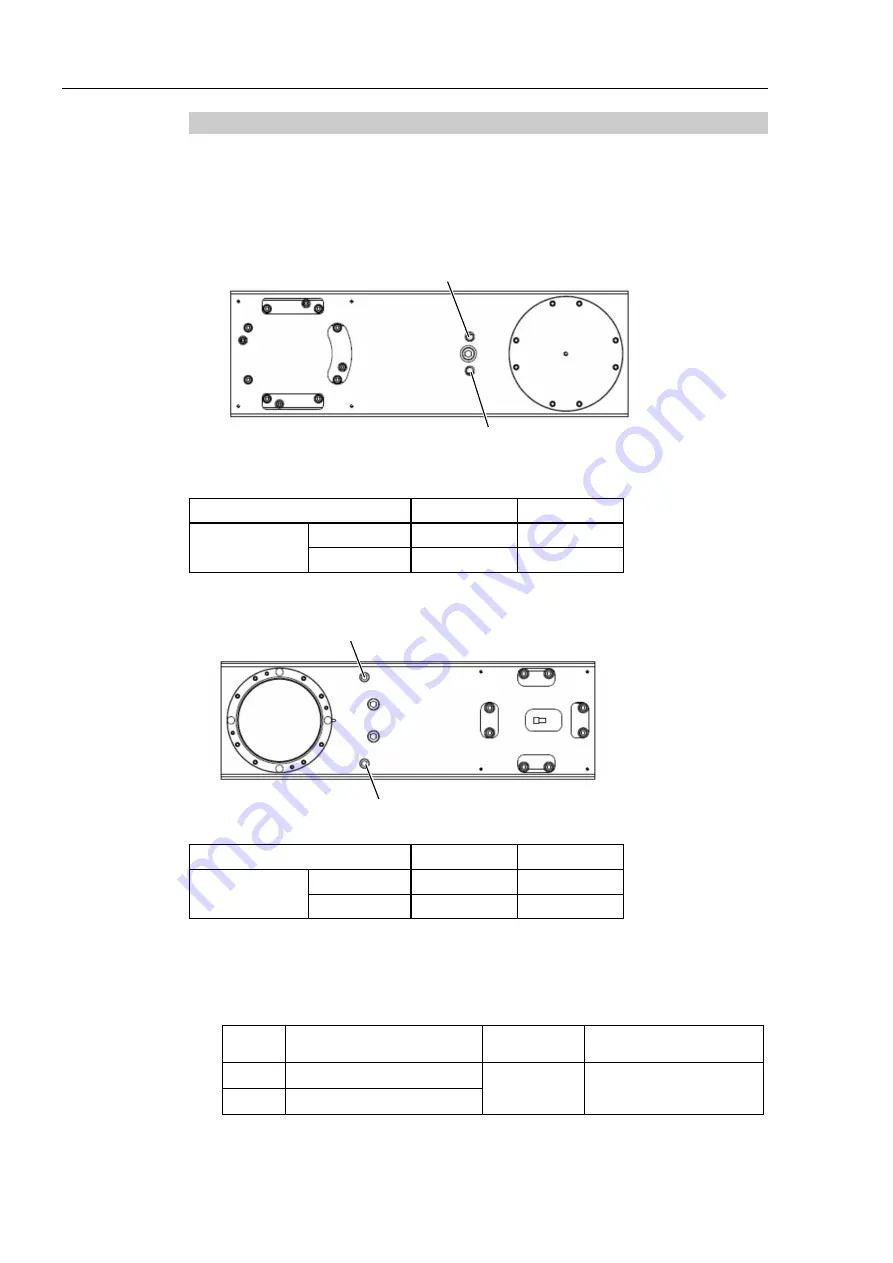

b

a

Views from the top of Arm #1

Joint #2 Mechanical Stops

a

b

LS20-804*

LS20-A04*

Setting Angle

135 deg

-

135 deg

Pulse Value

307200 pulse

-

307200 pulse

(1) Turn OFF the Controller.

(2) Install a hexagon socket head cap bolt into the hole corresponding to the setting angle,

and tighten it.

Joint Hexagon socket head cap

bolt (fully threaded)

The number

of bolts

Recommended

tightening torque

1

M10

×

65

1 bolt /

one side

13.0 N

⋅

m (132.7 kgf

⋅

cm)

2

M10

×

50

Summary of Contents for LS20

Page 1: ...Rev 4 EM179R3533F SCARA ROBOT LS20 series MANIPULATOR MANUAL ...

Page 2: ...MANIPULATOR MANUAL LS20 series Rev 4 ...

Page 8: ...vi LS20 Rev 4 ...

Page 12: ...TABLE OF CONTENTS x LS20 Rev 4 ...

Page 14: ......

Page 29: ...Setup Operation 2 Specifications LS20 Rev 4 17 LS20 804S Standard Model ...

Page 31: ...Setup Operation 2 Specifications LS20 Rev 4 19 LS20 804C Cleanroom Model ...

Page 33: ...Setup Operation 2 Specifications LS20 Rev 4 21 LS20 A04S Standard Model ...

Page 35: ...Setup Operation 2 Specifications LS20 Rev 4 23 LS20 A04C Cleanroom Model ...

Page 72: ......

Page 92: ...Maintenance 4 Cable 80 LS20 Rev 4 4 2 Wiring Diagrams 4 2 1 Signal Cable ...

Page 176: ...Maintenance 14 Maintenance Parts List 164 LS20 Rev 4 ...