Summary of Contents for LX-300

Page 1: ... EPSON TERM NAL PR NTER LX 300 SERVICE MANUAL EPSON ...

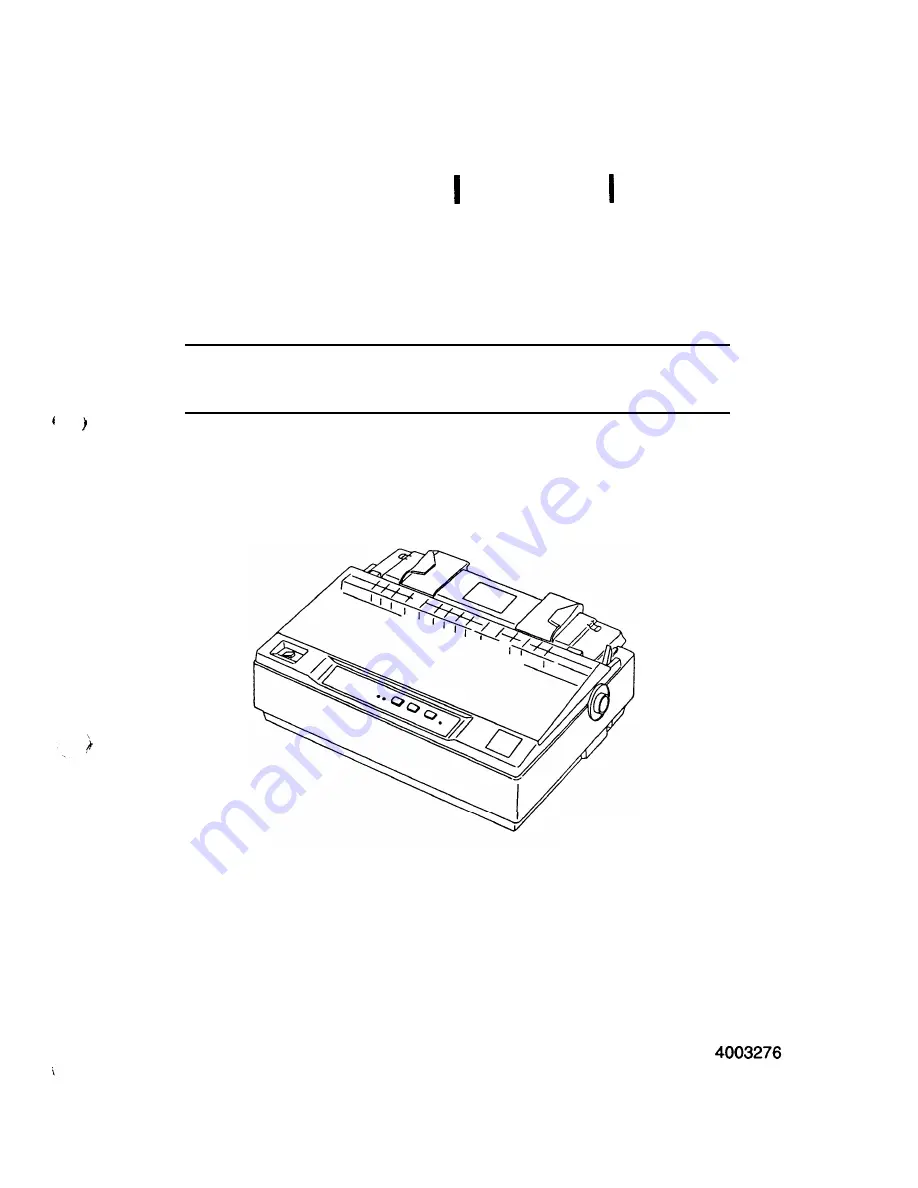

Page 4: ...REVISION SHEET Revision Issue Date Revision Page Rev A April 6 1994 1st issue 4 j v ...

Page 95: ...Maintenance LX 300 Service Manual k w n M IL f Figure 6 1 LX 300 Lubrication Points 6 2 Rev A ...