M200 / M205 / M100 / M105 Series

Revision A

Disassembly/Reassembly

Detailed Disassembly/Reassembly Procedure for each Part/Unit

52

Confidential

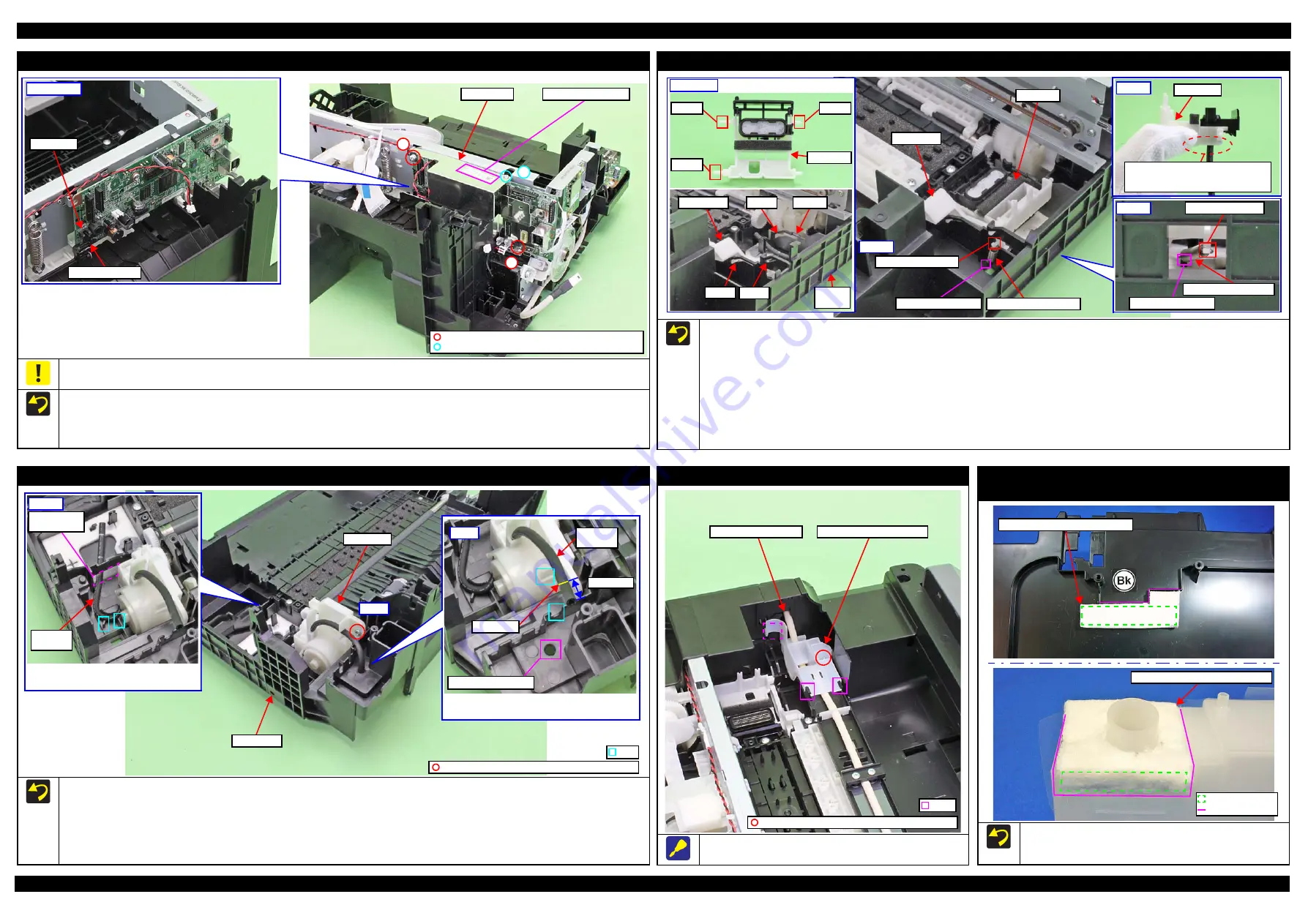

Main Board/Shield Plate

Do not damage or contaminate the MAC Address Label.

Install the Main Board with the PE Sensor Lever to the rear. After installing the Main Board, make sure the lever part of the PE Sensor Lever is

aligned with the slit of the PE Sensor.

Attach the MAC Address Label to the Shield Plate on the position indicated in the figure above.

Tighten the screws of the Shielded Plate in the order indicated in the figure above.

MAC Address Label

Shield Plate

Main Board

PE Sensor Lever

PE Sensor

1

2

3

C.B.S-TITE SCREW 3x6 F/ZN-3C (6 ± 1 kgf·cm)

C.B.S-TITE SCREW 2x4 F/ZN-3C (2 ± 0.5 kgf·cm)

Cap Lever / Cap Assy

When installing the Cap Lever/Cap Assy, follow the procedure below.

1. Attach the Cap Lever to the Frame Base, and attach one end of the Extension Spring 0.65 to the hook of the Frame Base.

2. Connect the tube of the Pump Unit to the joint on the bottom of the Cap Assy. Then, viewing from the side, confirm the marking (10 ± 1 mm

from the tube end) on the tube is covered by the Cap Slider.

3. Insert the shaft A of the Cap Assy through the hole of the Cap Lever to the hole A of the Frame Base.

4. Insert the shaft B of the Cap Assy through the cutout of the Frame Base and to the hole B of the Frame Base.

5. Insert the shaft C of the Cap Assy to the hole C of the Frame Base.

6. Using a “spring hook jig”

, attach the other end of the Extension Spring 0.65 to the hook of the Cap Assy.

7. Attach the Extension Spring 1.329 to the hooks of the Cap Lever and Frame Base.

Cap Lever

Extension Spring 1.329

Cap Assy

Extension Spring 0.65

Hook of Cap Assy

Hook of Frame Base

Step 6

Shaft B

Shaft A

Shaft C

Cap Assy

Step 2

Make sure the marking (10 ± 1 mm

from the tube end) on the tube cannot

be seen when viewed from the side.

Cap Slider

Cutout

Hole B

Cap Lever

Frame

Base

Hole A Hole C

Step 1, 3-5

Hook of Frame Base

Hook of Cap Lever

Step 7

Pump Unit

When installing the Pump Unit, follow the procedure below in order to prevent ink suction failure.

1. Route the Pump Tube A through the hole of the Frame Base.

2. Install the Pump Unit to the Frame Base, and route the Pump Tube A through the ribs of the Frame Base with their dashed line facing upward.

3. Secure the Pump Unit to the Frame Base with the screw (x1).

4. Route the Pump Tube B through the ribs of the Pump Unit and Frame Base, and insert it to the hole of the Frame Base up to the marking

(8

±

1 mm from tube end).

Step 4

Pump

Tube B

Marking

8 ± 1 mm

Hole of Frame Base

Hole of

Frame Base

Pump

Tube A

Step 1-2

Pump Unit

Route Pump Tube A through ribs of Frame

Base with their dashed line facing upward.

Insert Pump Tube B up to the marking (8 ± 1 mm

from tube end) to the hole of Frame Base.

C.B.P-TITE SCREW 3x10 F/ZN-3C (6 ± 1 kgf·cm)

Step 3

Frame Base

Rib

Ink Supply Tube Guide 1st

To remove the Ink Supply Tube Guide 1st, remove the screw and

release the three hooks, then release the Ink Supply Tank Tube.

Ink Supply Tube Guide 1st

C.B.P-TITE SCREW 3x10 F/ZN-3C (6 ± 1 kgf·cm)

Hook

Ink Supply Tank Tube

Ink Supply Tank Side Porous Pad /

Ink Supply Tank Upper Porous Pad

When attaching the Ink Supply Tank Side Porous Pad/Ink Supply

Tank Upper Porous Pad, align them with the standard line shown in

the above figure.

Ink Supply Tank Side Porous Pad

Ink Supply Tank Upper Porous Pad

Double-sided tape

Standard line

Summary of Contents for M200

Page 1: ...SERVICE MANUAL CONFIDENTIAL Color Inkjet Printer M200 M201 M205 M100 M101 M105 SEMF12 012 ...

Page 9: ...Confidential CHAPTER 1 TROUBLESHOOTING ...

Page 18: ...Confidential CHAPTER 2 DISASSEMBLY REASSEMBLY ...

Page 59: ...Confidential CHAPTER 3 ADJUSTMENT ...

Page 73: ...Confidential CHAPTER 4 MAINTENANCE ...