M200 / M205 / M100 / M105 Series

Revision A

Disassembly/Reassembly

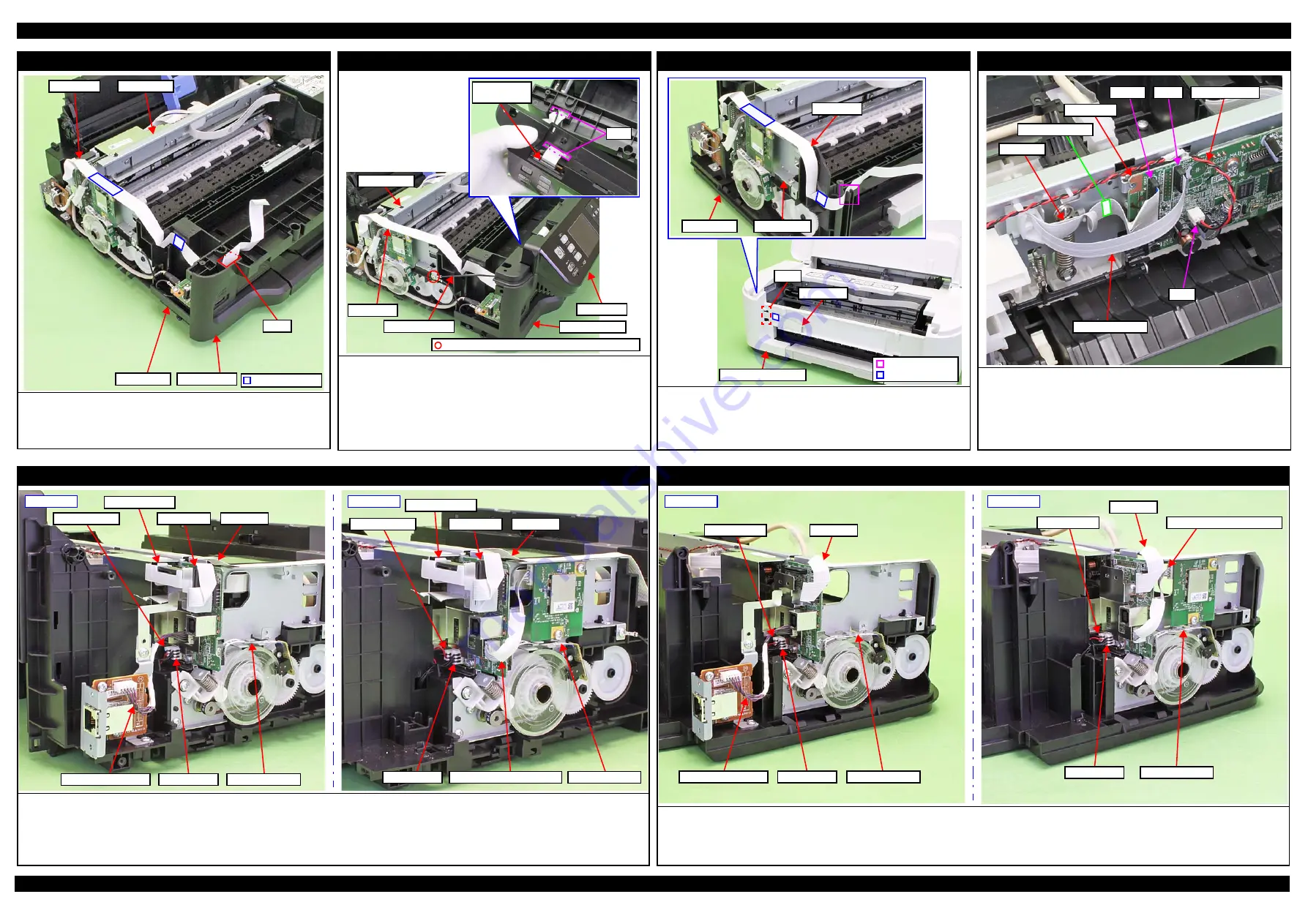

Routing FFCs/cables

57

Confidential

Panel FFC (M200/M205 Series)

Route the Frame Base and Main Frame along the folded line and secure

with the double-sided tape on the position shown in the above.

After installing the Housing Front, route the Panel FFC through the hole

of the Housing Front.

Housing Front

Main Frame

Panel FFC

Frame Base

Hole

Double-sided tape

Panel Unit (M200/M205 Series)

Route the Panel FFC and grounding wire as follows before installing the

Panel Unit.

•

Route the Panel FFC through the hole of the Panel Unit and connect the

connector of the Panel Board.

•

Route the grounding wire through the hole of the Housing Front.

After installing the Panel Unit, secure the grounding wire to the Main

Frame on the position indicated in the figure above with screw (x1).

Hole

Connector of

Panel Board

Main Frame

Panel FFC

Grounding wire

Housing Front

Panel Unit

C.B.S-TITE SCREW 3x6 F/ZN-3C (6 ± 1 kgf·cm)

Panel FFC (M100/M105 Series)

Route the Panel FFC through the rib of the Frame Base and Main Frame

along the folded line and secure with the double-sided tape on the position

shown above.

Route through the hole of the Housing Upper Assy and secure with the

double-sided tape on the position shown above.

Rib

Double-sided tape

Panel FFC

Frame Base

Main Frame

Housing Upper Assy

Panel FFC

Hole

Right side of Main Board

Connect the following cables/FFCs to the Main Board as shown in the figure

above.

•

CR Motor cable (CN12)

•

CR Encoder FFC (CN6)

•

Head FFC (CN102)

Secure with the double-sided tape on the position shown above.

Main Board

CN12

CN102

Head FFC

CR Encoder FFC

CN61

CR Motor cable

Double-sided tape

Left side of Main Board (M200/M205 Series)

Connect the following cables/FFCs to the Main Board as shown above.

• PF Motor cable (CN13)

• PS Unit cable (CN501)

• Wireless LAN Module Cable (CN4: only for M205 Series)

• PF Encoder FFC (CN7)

• Ethernet Board cable (CN14: only for M200 Series)

• Panel FFC (CN2) : Secure the ferrite core of the FFC Holder MB and connect to the Main Board through the ferrite core.

M205 Series

PS Unit cable

PF Encoder FFC

Wireless LAN Module Cable

FFC Holder MB

Ferrite core

Panel FFC

PF Motor cable

M200 Series

PF Motor cable

PS Unit cable

PF Encoder FFC

FFC Holder MB

Ferrite core

Panel FFC

Ethernet Board cable

Left side of Main Board (M100/M105 Series)

Connect the following cables/FFCs to the Main Board as shown above.

• PF Motor cable (CN13)

• PS Unit cable (CN501)

• Wireless LAN Module Cable (CN4: only for M105 Series)

• PF Encoder FFC (CN7)

• Ethernet Board cable (CN14: only for M100 Series)

• Panel FFC (CN2)

M100 Series

Ethernet Board cable

PS Unit cable

PF Encoder FFC

PF Motor cable

Panel FFC

M105 Series

PS Unit cable

PF Encoder FFC

PF Motor cable

Panel FFC

Wireless LAN Module Cable

Summary of Contents for M200

Page 1: ...SERVICE MANUAL CONFIDENTIAL Color Inkjet Printer M200 M201 M205 M100 M101 M105 SEMF12 012 ...

Page 9: ...Confidential CHAPTER 1 TROUBLESHOOTING ...

Page 18: ...Confidential CHAPTER 2 DISASSEMBLY REASSEMBLY ...

Page 59: ...Confidential CHAPTER 3 ADJUSTMENT ...

Page 73: ...Confidential CHAPTER 4 MAINTENANCE ...