Maintenance 4. Cable

214

N6 Rev.2

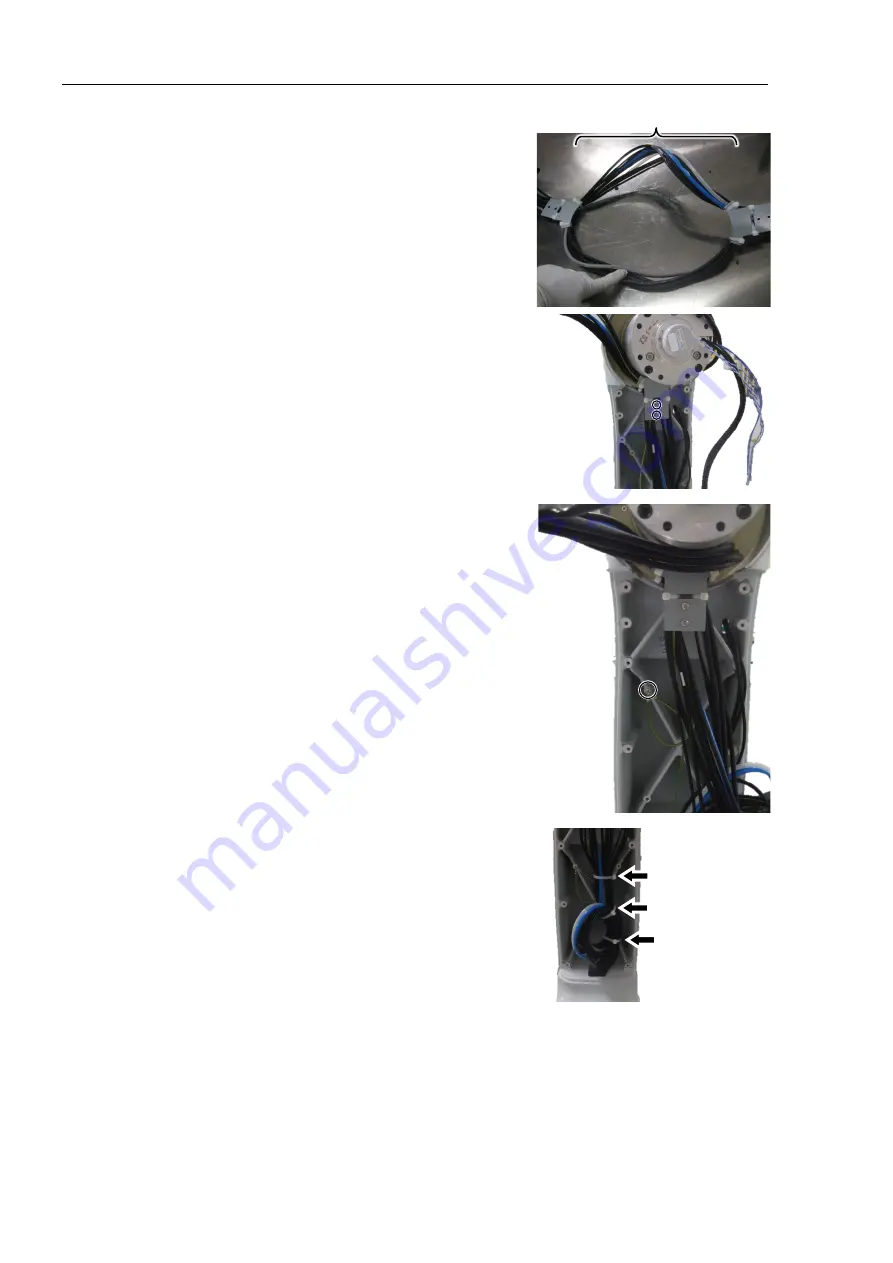

(17) Apply the grease to the cables between the

two cable fixing plates.

Grease:

Krytox: Cable A and B

Standard model

: 1g for each

Cleanroom model : 1.5g for each

Apply the grease to each cable evenly.

Grease application range

(18) Install the cable fixing plates to Arm #1.

Hexagon socket head cap bolts: 2-M4×8

Tightening torque: 4.0

±

0.2 N·m

Be careful not to tighten the screws with the

cables get caught on the plate.

(19) Install the two ground wire terminals.

Cross recessed binding head machine screw:

M4×8

Tightening torque: 0.9

±

0.1 N·m

(20) Install the cable unit as shown on the right,

and then bundle three positions with the

cable ties.

Fix one position to the Arm #1.

Cable ties (AB200)

Fix to the Arm #1

NOTE

NOTE

Summary of Contents for N6 Series

Page 1: ...Rev 2 EM187R3735F 6 Axis Robots N6 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual N6 series Rev 2 ...

Page 8: ...vi N6 Rev 2 ...

Page 14: ......

Page 27: ...Setup Operation 1 Safety N6 Rev 2 15 N6 A850 R C A D F G F E H G F B G F G F F F N6 A850 BR F ...

Page 34: ...Setup Operation 2 Specifications 22 N6 Rev 2 N6 A850 BR Cable direction Upward ...

Page 52: ...Setup Operation 3 Environment and Installation 40 N6 Rev 2 N6 A850 R Maximum motion range 802 ...

Page 66: ...Setup Operation 4 End Effectors 54 N6 Rev 2 N6 A850 R Unit mm ...

Page 104: ......

Page 274: ...Maintenance 4 Cable 262 N6 Rev 2 4 7 1 Signal Power cable ...

Page 275: ...Maintenance 4 Cable N6 Rev 2 263 ...

Page 276: ...Maintenance 4 Cable 264 N6 Rev 2 4 7 2 User Cable ...