Maintenance 5. Actuator Units

N6 Rev.2

305

Removal

(1) Turn ON the Controller.

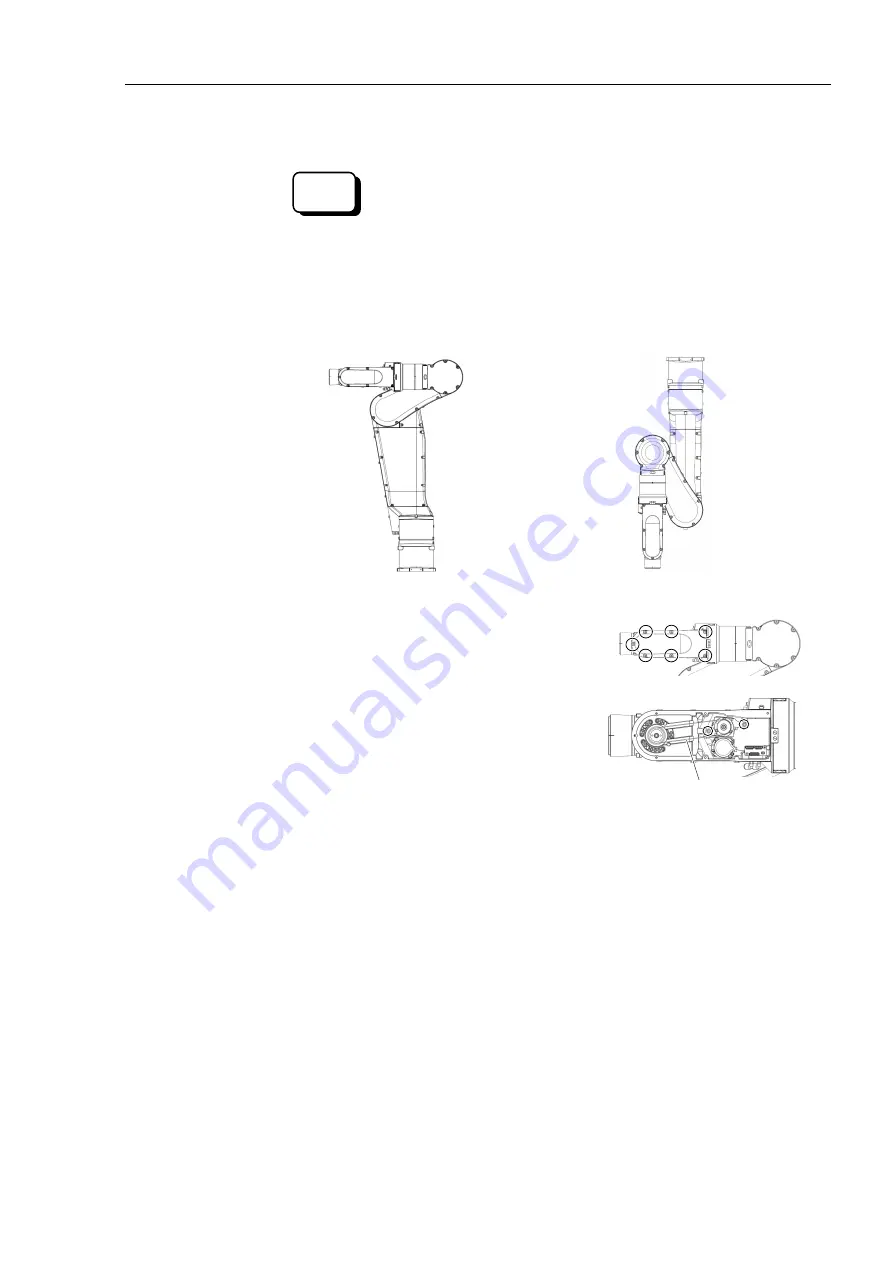

Joint #5

timing belt:

(2) Release the brake on the Joint #2 and Joint #3.

EPSON

RC+

Command

> brake off, 2

> brake off, 3

When releasing the brake, be careful of the arm falling due to its own weight.

(3)

Move the angles of the Arm #2 and the Arm #3 about 30 degrees from the origin

positions.

N6-A1000**

N6-A850**R

(4) Turn OFF the Controller.

(5) Remove the Arm #4 side cover.

Cross recessed binding head machine screw:

7-M4×8

(6) Loosen the screws fixing the Arm #4 and the

Joint #5 motor unit. Then, remove the timing

belt of the Joint #5.

Hexagon socket head cap bolts: 2-M4×15

(with plain washer for slotted hole

thickness: 1.5mm)

Timing belt

If a heavy part such as end effector is installed on the end of the Manipulator, the

Arm #5 will move. Be very careful.

NOTE

NOTE

Summary of Contents for N6 Series

Page 1: ...Rev 2 EM187R3735F 6 Axis Robots N6 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual N6 series Rev 2 ...

Page 8: ...vi N6 Rev 2 ...

Page 14: ......

Page 27: ...Setup Operation 1 Safety N6 Rev 2 15 N6 A850 R C A D F G F E H G F B G F G F F F N6 A850 BR F ...

Page 34: ...Setup Operation 2 Specifications 22 N6 Rev 2 N6 A850 BR Cable direction Upward ...

Page 52: ...Setup Operation 3 Environment and Installation 40 N6 Rev 2 N6 A850 R Maximum motion range 802 ...

Page 66: ...Setup Operation 4 End Effectors 54 N6 Rev 2 N6 A850 R Unit mm ...

Page 104: ......

Page 274: ...Maintenance 4 Cable 262 N6 Rev 2 4 7 1 Signal Power cable ...

Page 275: ...Maintenance 4 Cable N6 Rev 2 263 ...

Page 276: ...Maintenance 4 Cable 264 N6 Rev 2 4 7 2 User Cable ...