Maintenance 5. Actuator Units

N6 Rev.2

321

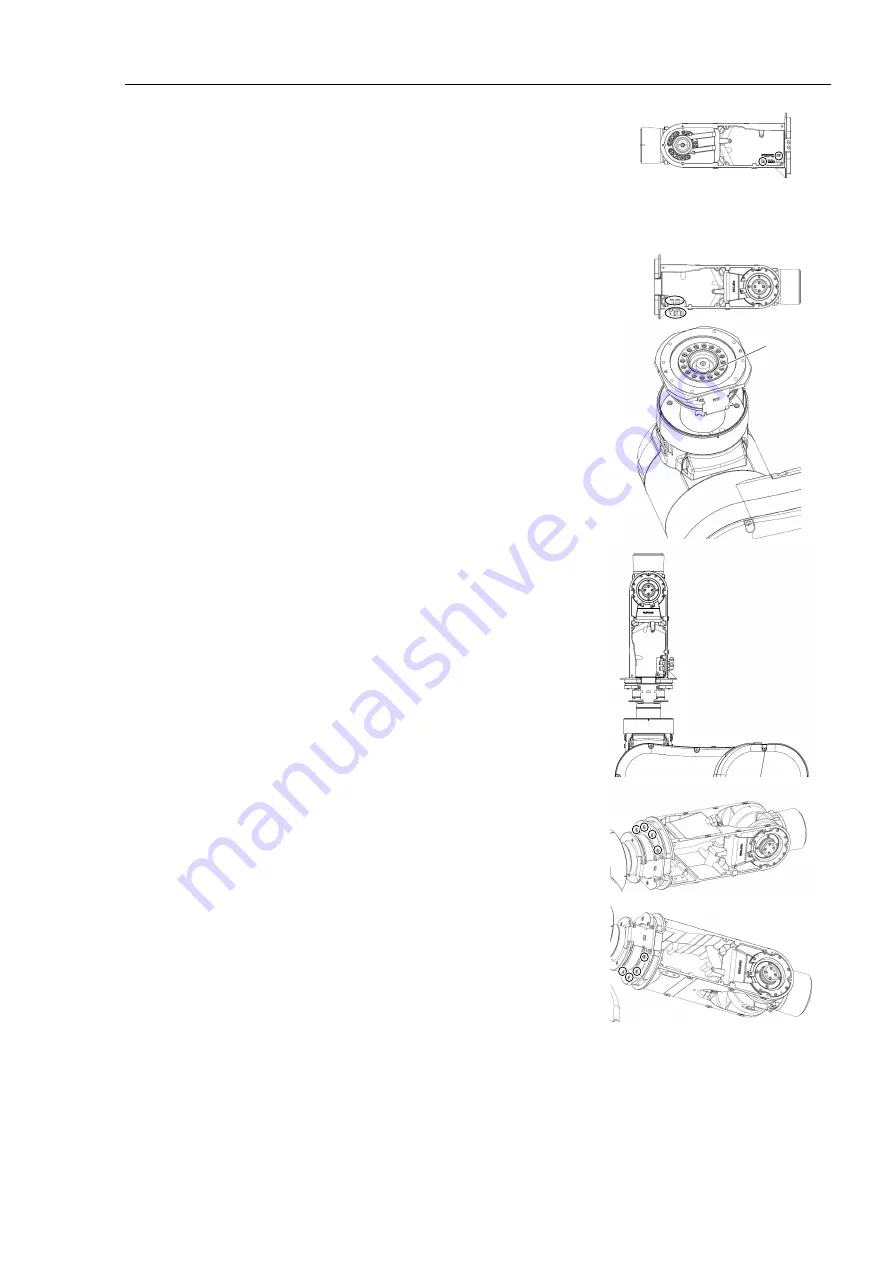

Installation

Joint #5 and #6

Unit

(1) Install the encoder board #4 to the Joint #5 and

#6 units.

Cross recessed binding head machine screws:

2-M3×6

Tightening torque: 0.45

±

0.05 N·m

(2) Install the air tube fittings to the Joint #5 and #6

units.

(3) Install the O-ring to the Joint #4 flange.

O-ring Inner diameter ø 47.5 mm

Wire diameter ø 2.0 mm

Apply a thin coat of grease to the O-ring.

Grease: SK-1A

O-ring

(4) Install the Joint #5 and #6 units on the Joint #4

actuator unit.

Hexagon socket head cap bolts:

8-M4×20 (with plain washer)

Tightening torque: 5.5±0.25 N·m

Be sure to have at least 2 people to perform the

operation since the parts being heavy.

Confirm that the two pins are installed on the

Joint #4 flange. When installing it, make sure to

align the pins with the Joint #5 and #6 units.

Be sure to install the O-ring properly.

Be careful not to get the cables caught in the

units and the actuator unit.

NOTE

NOTE

Summary of Contents for N6 Series

Page 1: ...Rev 2 EM187R3735F 6 Axis Robots N6 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual N6 series Rev 2 ...

Page 8: ...vi N6 Rev 2 ...

Page 14: ......

Page 27: ...Setup Operation 1 Safety N6 Rev 2 15 N6 A850 R C A D F G F E H G F B G F G F F F N6 A850 BR F ...

Page 34: ...Setup Operation 2 Specifications 22 N6 Rev 2 N6 A850 BR Cable direction Upward ...

Page 52: ...Setup Operation 3 Environment and Installation 40 N6 Rev 2 N6 A850 R Maximum motion range 802 ...

Page 66: ...Setup Operation 4 End Effectors 54 N6 Rev 2 N6 A850 R Unit mm ...

Page 104: ......

Page 274: ...Maintenance 4 Cable 262 N6 Rev 2 4 7 1 Signal Power cable ...

Page 275: ...Maintenance 4 Cable N6 Rev 2 263 ...

Page 276: ...Maintenance 4 Cable 264 N6 Rev 2 4 7 2 User Cable ...