Maintenance 8. Calibration

352

N6 Rev.2

8. Calibration

8.1. Overview

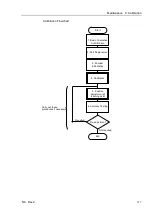

After parts (actuator units, timing belts, etc.) or the battery board have been replaced, the

Manipulator cannot perform positioning properly because a gap exists between the origin

stored in each actuator unit and its corresponding origin stored in the Controller.

After replacing the parts, it is necessary to match these origins.

The process of aligning the two origins is called “Calibration”.

Note that calibration is not the same as teaching*

* “Teaching” means to teach the Controller coordinate points (including poses) anywhere

in the operating area of the Manipulator.

WARNING

■

To ensure safety, a safeguard must be installed for the robot system. For details

on the safeguard, refer to the

Installation and Design Precautions

in the

Safety

chapter of the

EPSON RC+ User’s Guide

.

■ Before operating the robot system, make sure that no one is inside the

safeguarded area. The robot system can be operated in the mode for teaching

even when someone is inside the safeguarded area. The motion of the

Manipulator is always in restricted (low speeds and low power) status to secure

the safety of an operator. However, operating the robot system while someone

is inside the safeguarded area is extremely hazardous and may result in serious

safety problems in case that the Manipulator moves unexpectedly.

There are two methods to move the Manipulator during calibration.

- Releasing the Electromagnetic brake and moving the arms manually.

For details, refer to the

Setup & Operation 1.5 How to Move Arms with the

Electromagnetic brake.

- Moving the Manipulator using Jog & Teach.

For details of Jog & Teach, refer to the following manual.

EPSON RC+ User's Guide 5.11.1 [Robot Manager] Command (Tools Menu)-[Jog and

Teach]

Moving the Manipulator while releasing the Electromagnetic brake involves risk as

described below.

CAUTION

■

Normally, release the brake of joints one by one. Take extra care if you need to

release the brakes of two or more joints simultaneously. Releasing the brakes

of two or more joints simultaneously may cause hands and fingers to be caught

and/or equipment damage to or malfunction of the Manipulator as the arms of the

Manipulator may move in unexpected directions.

■

Be careful of the arm falling when releasing the brake.

While the brake is being released, the Manipulator’s arm falls by its own weight.

The arm falling may cause hands and fingers to be caught and/or may cause

equipment damage to or malfunction of the Manipulator.

Summary of Contents for N6 Series

Page 1: ...Rev 2 EM187R3735F 6 Axis Robots N6 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual N6 series Rev 2 ...

Page 8: ...vi N6 Rev 2 ...

Page 14: ......

Page 27: ...Setup Operation 1 Safety N6 Rev 2 15 N6 A850 R C A D F G F E H G F B G F G F F F N6 A850 BR F ...

Page 34: ...Setup Operation 2 Specifications 22 N6 Rev 2 N6 A850 BR Cable direction Upward ...

Page 52: ...Setup Operation 3 Environment and Installation 40 N6 Rev 2 N6 A850 R Maximum motion range 802 ...

Page 66: ...Setup Operation 4 End Effectors 54 N6 Rev 2 N6 A850 R Unit mm ...

Page 104: ......

Page 274: ...Maintenance 4 Cable 262 N6 Rev 2 4 7 1 Signal Power cable ...

Page 275: ...Maintenance 4 Cable N6 Rev 2 263 ...

Page 276: ...Maintenance 4 Cable 264 N6 Rev 2 4 7 2 User Cable ...