EPSON PhotoPC 800

Revision A

Operating Principle

Operating principles of the Circuit Boards

43

2.2.2.3 LCD Block

During monitoring, YUV conversion is carried out for the 10-bit CCD data which

is input from the A/D conversion block to the ASIC and is then transferred to

the DRAM so that the CCD data can be displayed on the LCD.

The data which has accumulated in the DRAM is passed through the NTSC

encoder, and after D/A conversion is carried out to change the data into a Y/C

signal, the data is sent to the LCD panel and displayed.

If the shutter button is pressed in this condition, the 10-bit data which is output

from the A/D conversion block of the CCD is sent to the DRAM (DMA transfer),

and after processor, it is displayed on the LCD as a freeze-frame image.

During playback, the JPEG image data which has accumulated in the flash

memory is converted to YUV signals, and then in the same way as during

monitoring, it is passed through the NTSC encoder, and after D/A conversion is

carried out to change the data into a Y/C signal, the data is sent to the LCD

panel and displayed. The two analog signal (Y/C signals) from the ASIC are

converted into RGB signals by the LCD driver, and these RGB signals and the

control signal which is output by the LCD driver are used to drive the LCD

panel. The RGB signals are 1H transposed so that no DC component is

present in the LCD element, and the two horizontal shift register clocks drive

the horizontal shift registers inside the LCD panel so that the 1H transposed

RGB signals are applied to the LCD panel. Because the LCD closes more as

the difference in potential between the COM (common polar voltage: fixed at

DC) and the R, G and B signals becomes greater, the display becomes darker;

if the difference in potential is smaller, the element opens and the LCD become

brighter.

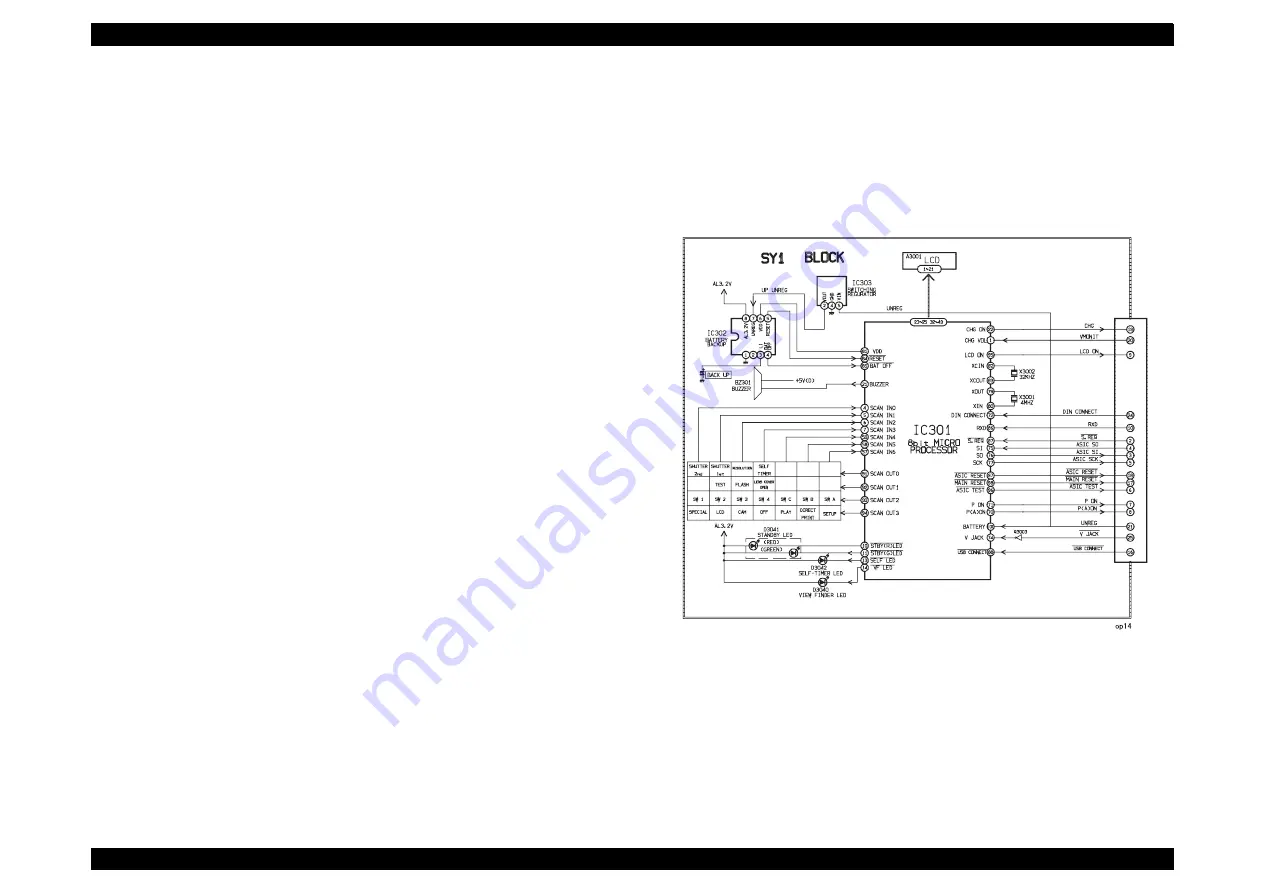

2.2.3 SY1 Circuit Description

2.2.3.1 Configuration and Functions

For the overall configuration of the SY1 circuit board, refer to the block

diagram. The configuration of the SY1 circuit board centers around a 8-bit

microprocessor (IC301).

Figure 2-13. SY1 Circuit Block Diagram

The 8-bit microprocessor handles the following functions;

1. Operation Key

2. Mode LCD display

3. Clock control

4. Power ON/OFF

5. Strobe charge control

Summary of Contents for PhotoPC 800

Page 1: ...EPSONPhotoPC800 Digital Still Camera SEDC99002 6 59 0 18 6 59 0 18 6 59 0 18 6 59 0 18 ...

Page 5: ...Revision Status Revision Issued Date Description A June 10 1999 First Release ...

Page 8: ... 3 7 5 4 PRODUCT DESCRIPTION ...

Page 32: ... 3 7 5 5 OPERATINGPRINCIPLE ...

Page 52: ... 3 7 5 6 TROUBLESHOOTING ...

Page 55: ... 3 7 5 7 DISASSEMBLYANDASSEMBLY ...

Page 74: ... 3 7 5 8 ADJUSTMENT ...

Page 90: ... 3 7 5 9 MAINTENANCE ...

Page 92: ... 3 7 5 APPENDIX ...

Page 94: ......

Page 96: ...ca1_pcb ...

Page 97: ...ca2_pcb ...

Page 98: ...sy1_pcb ...

Page 99: ...pw1_pcb ...

Page 101: ......

Page 102: ...NTSC ...

Page 103: ...PAL ...

Page 104: ......

Page 105: ......

Page 110: ......